Method for calculating length of head subcooling region and length of tail subcooling region in water cooling process of steel plate

A technology of supercooling zone and steel plate, applied in the direction of tail end control, temperature control, workpiece cooling device, etc., can solve the problem of inaccurate setting of the length of supercooling zone, achieve the effect of getting rid of one-sidedness, facilitating analysis and realizing data management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

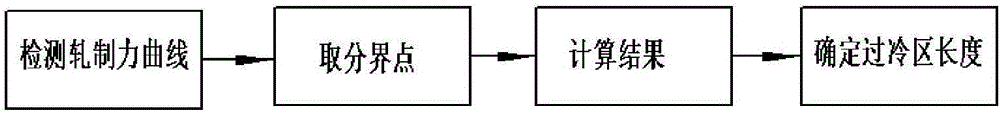

[0016] A method for calculating the length of the head-to-tail supercooling zone in the steel plate water cooling process, the steps are:

[0017] 1) Find the rolling process data of a certain steel type according to the secondary data of the rolling mill, such as Q345B, and collect the rolling force curve during the rolling process;

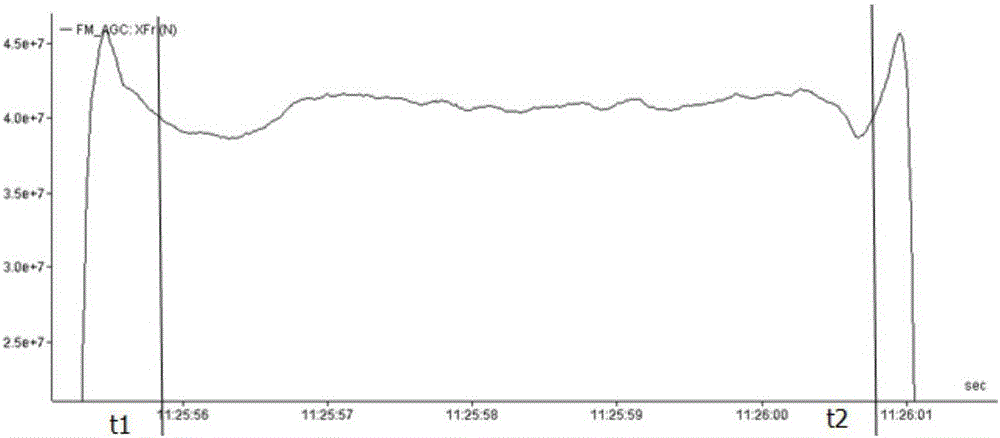

[0018] 2) According to the rolling force curve of the last rolling pass, take the length of time corresponding to the 10% difference between the rolling force of the head and tail rolling process and the stable rolling, for example, the rolling force curve of the last pass is 4000KN during stable rolling , while the rolling force at the head position of the rolled piece exceeds 10% for 0.3s;

[0019] 3) According to the speed curve of the rolling process, the rolling speed is 2m / s;

[0020] 4) Length L1 of the supercooled zone at the head = t*v=2*0.3=0.6m.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com