Method for preparing livestock wastewater adsorbent from acid modified kaolin

A technology of kaolin and acid modification, which is applied in the field of environmental pollutant adsorption materials, and can solve problems such as poor effect of bentonite on wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Preparation of livestock and poultry wastewater phosphorus adsorption material:

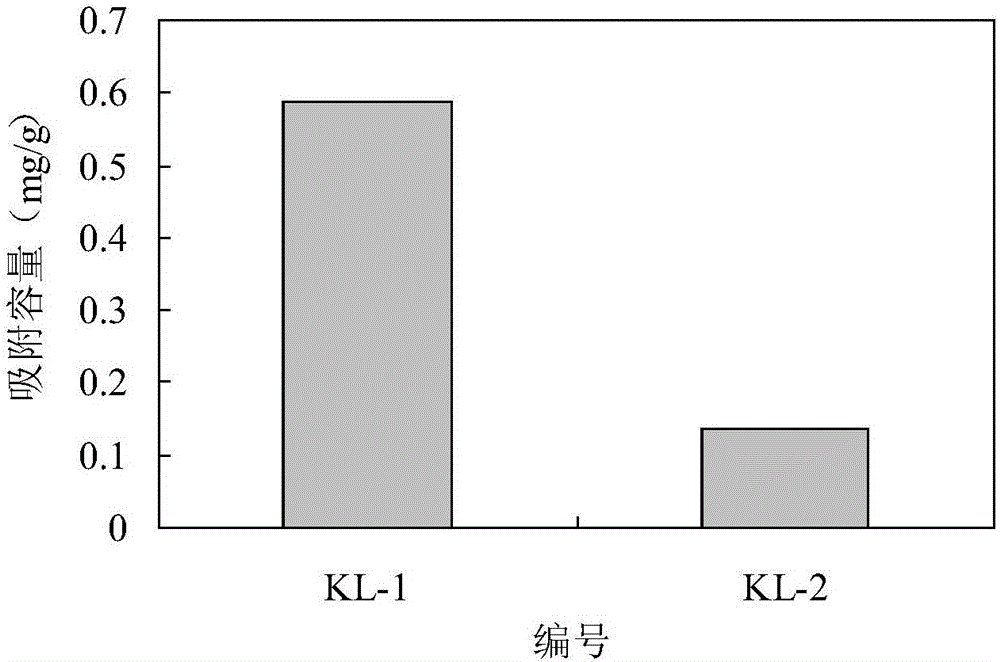

[0021] 1) Screening of natural kaolin: There are two kinds of kaolin for testing, which are from Jiangsu Suzhou (KL-1) and Sinopharm Co., Ltd. (KL-2). Accurately weigh 0.5g of two different kaolin mineral materials into a 150mL centrifuge tube, add 50mL of simulated wastewater with a phosphorus concentration of 50mg / L at a constant temperature (20±1)°C, shake at 180r / min for 1h, and let stand for 24h , centrifuge at 4 000r / min for 10min, separate the supernatant, measure the phosphorus content, calculate the amount of phosphorus adsorbed according to the concentration change, and screen out the kaolin with phosphorus adsorption capacity as the next experimental material.

[0022] 2) Preparation of modified kaolin with different acid concentrations: Take 30 g of kaolin in a round bottom flask, add 250 mL of hydrochloric acid solution with different concentrations (1%, 3%, 9% b...

Embodiment 2

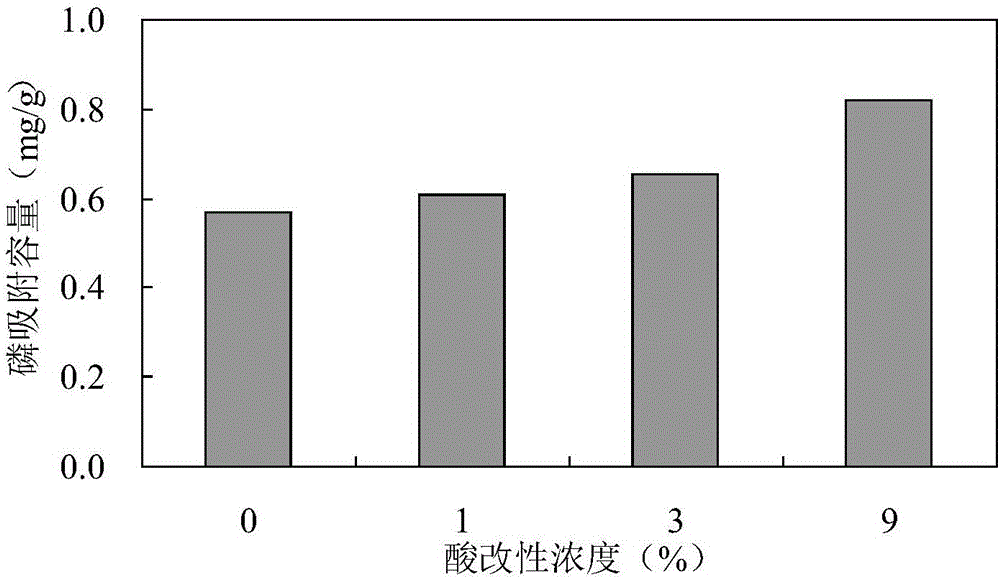

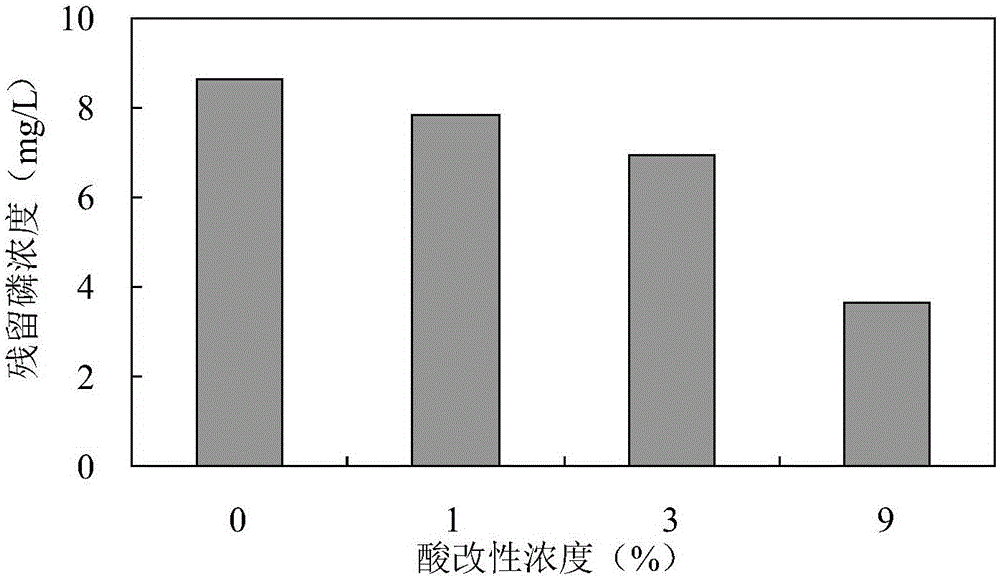

[0030] Embodiment 2: Comparison of the adsorption capacity of different concentrations of acid-modified kaolin to phosphorus:

[0031] Accurately weigh 0.5 g of the acid-modified sample into a 150 mL centrifuge tube, and add 25 mL of simulated wastewater solution with a phosphorus concentration of 20 mg / L. Under constant temperature (20±1)°C, shake at 200r / min for 24h, centrifuge at 4000r / min for 10min, separate the supernatant, and measure the concentration of phosphorus. According to the change of initial and final concentration, calculate the amount of phosphorus adsorbed by it. The results showed that with the increase of the amount of acid, the adsorption capacity of modified kaolin for phosphorus gradually increased ( figure 2 ). Considering the consumption cost and practical operability of hydrochloric acid, the maximum dosage of hydrochloric acid in this test is 9% (V / V). When the amount of acid is 9%, the adsorption capacity of kaolin to phosphorus is 0.82mg / g, an...

Embodiment 3

[0032] Embodiment 3: the adsorption isotherm curve of optimum concentration acid-modified kaolin to phosphorus:

[0033] Accurately weigh 0.5g of the best acid-modified sample and its natural sample into a 150mL centrifuge tube, add 50mL of phosphorus containing , 200, 400mg / L simulated wastewater solution. Shake at a constant temperature (20±1)°C for 24 hours, and the rest of the steps are the same as above, and draw the phosphorus isotherm adsorption curve. The adsorption of phosphorus by natural kaolin increases with the concentration of phosphorus in the solution, and the slope of the curve gradually decreases from large to finally reaches equilibrium, showing the characteristics of monomolecular layer adsorption. It can be seen that with the increase of phosphorus adsorption by kaolin, its The adsorption affinity of phosphorus gradually decreases; while the acid-modified kaolin increases with the increase of phosphorus concentration, the slope of the curve increases at f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com