Automatic control method for combustion of cement decomposition furnace

A cement calcining furnace and calcining furnace technology, which can be used in furnaces, charging materials, rotary drum furnaces, etc., can solve problems such as high energy consumption, unstable quality, and economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

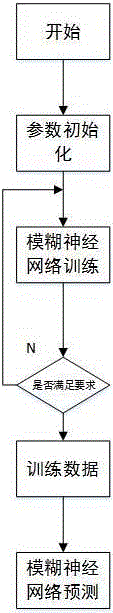

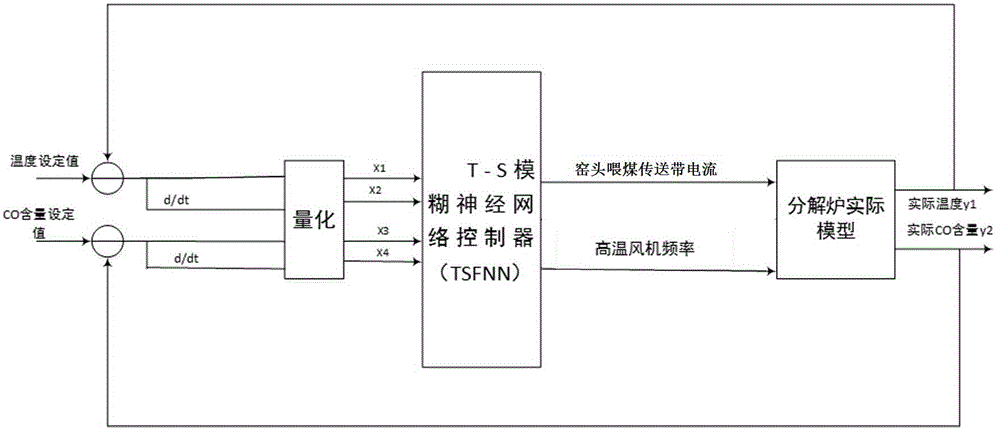

[0057] Combine below Figure 1 to Figure 2 Examples of the present invention are further described in figure 1 System block diagram. First, collect data on site, mainly coal consumption and kiln head coal feeding conveyor belt current, calciner outlet temperature, CO content in exhaust gas, and high-temperature fan frequency data. Abnormal data processing is performed on the data to obtain training data and test data. As well as determine the relationship between coal consumption and current, and the approximate relationship between fan frequency and oxygen.

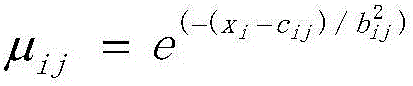

[0058] The inventor combines the BP algorithm of the neural network with the T-S fuzzy control to form an algorithm, and its algorithm module is in figure 1 T-S fuzzy neural network control. exist figure 1 The quantification in is as follows, the temperature difference at the outlet of the calciner, the threshold range of the temperature difference change is -40,40, so the fuzzy subset universe corresponding to X1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com