Disc-shaped memory alloy damper

A technology of memory alloy and memory alloy wire, which is applied to building components, building structures, building types, etc., can solve the problems of large plastic residual deformation of mild steel dampers, high maintenance cost of viscous dampers, and large residual friction dampers. Deformation and other problems, to achieve the effect of optimization of seismic performance, improvement of seismic performance, and improvement of bending bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

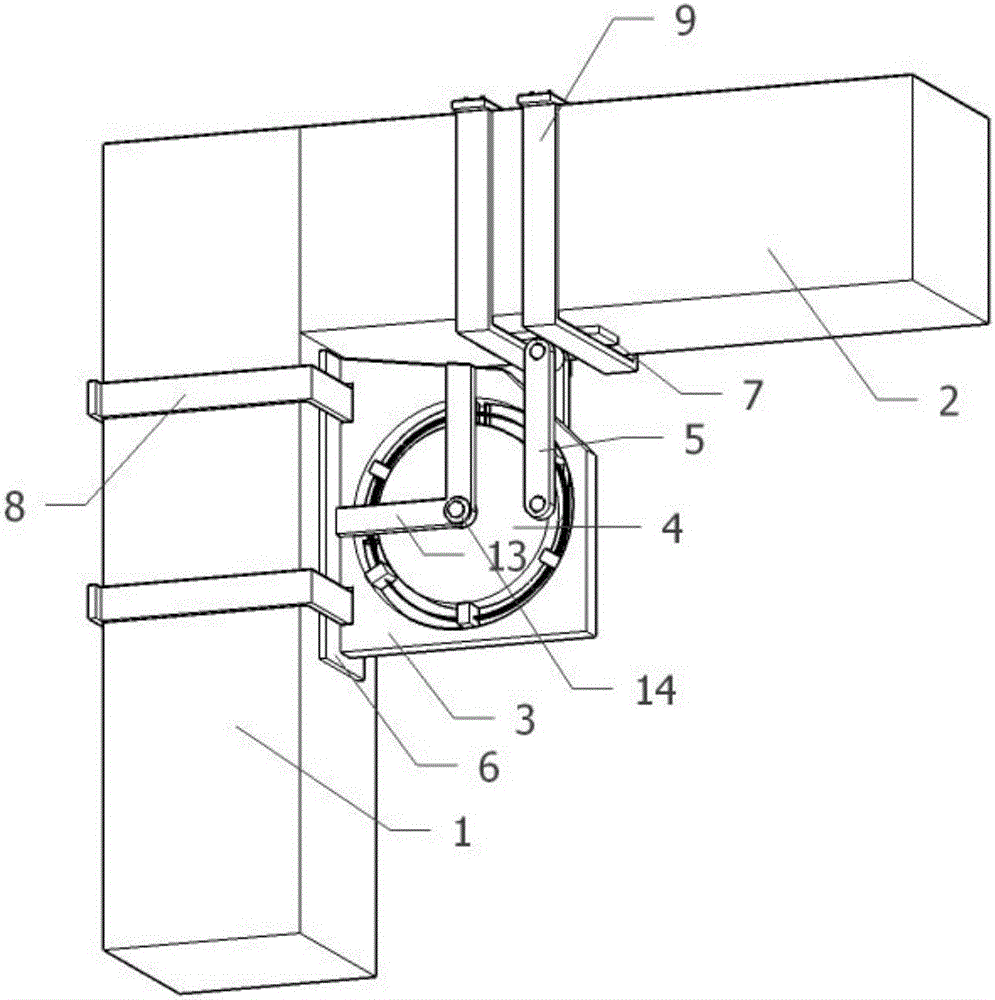

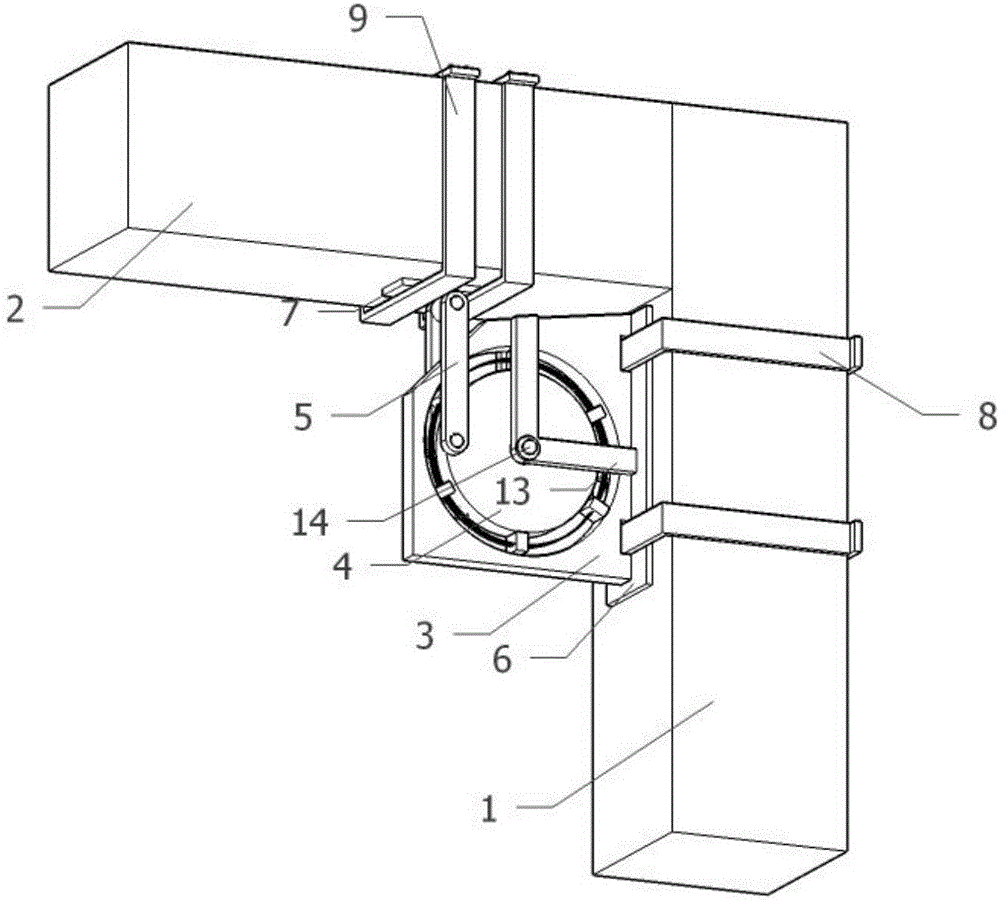

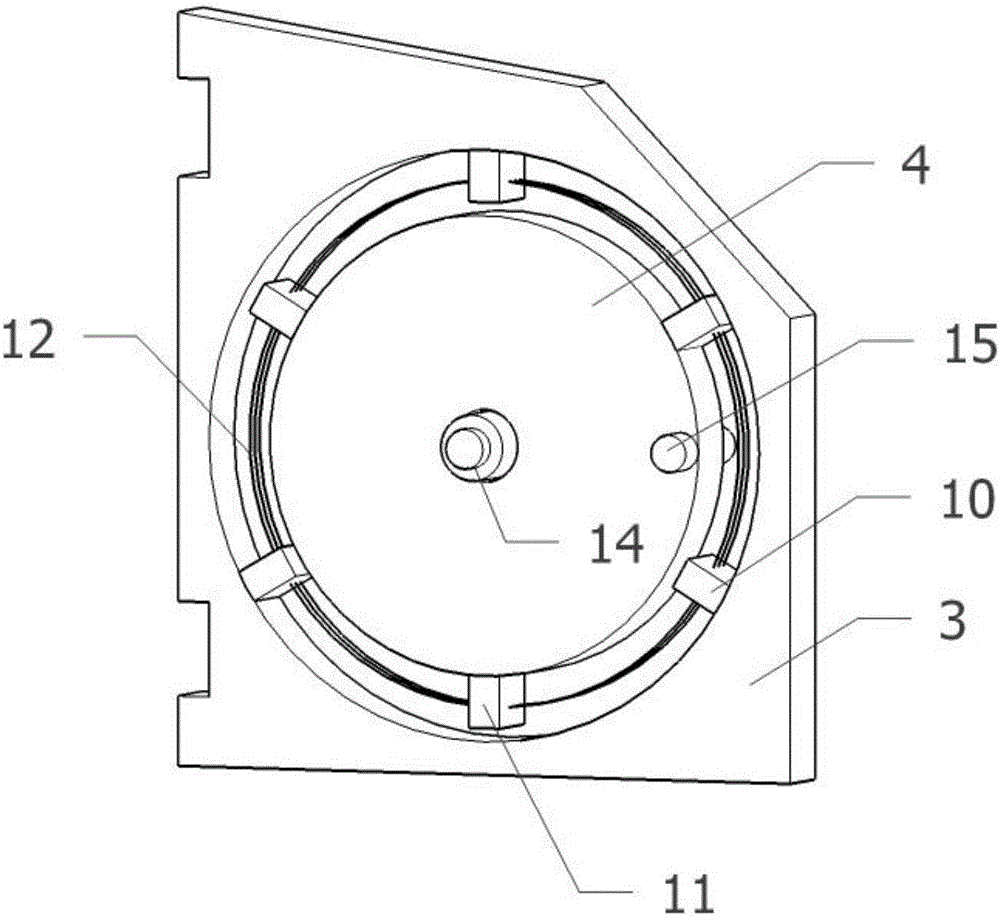

[0030] like figure 1 , figure 2 As shown, a disk shape memory alloy damper includes a wooden column 1 and a wooden beam 2 connected to the wooden column 1, and a base 3 is connected at the corner where the wooden column 1 and the wooden beam 2 are connected, and the base 3 is provided with There is a rotating disk 4 that can rotate along it, and the base 3 is fixed on the inside of the wooden column 1 through a vertically connected steel plate 6 and a wooden column clamp 8; the rotating disk 4 is connected to its central circular shaft 14 through an L-shaped fixed steel plate 13 It is connected with the vertically connected steel plate 6 and the wooden beam 2, and the rotating disk 4 is connected to the bottom surface of the wooden beam 2 through the rigid tie rod 5 to connect its ec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com