Natural composite preservative special for chilled fresh meat

A technology of preservative and chilled meat, which is applied in the fields of using chemicals to preserve meat/fish, biochemical equipment and methods, microorganisms, etc. , the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1, the acquisition of plantaractobacillus b-2

[0052] 1. Strain screening

[0053] 1. Weigh 25 g of sour kimchi, add it to 225 mL of sterile normal saline, and take 200 μL of the diluted solution after 10-fold gradient dilution with sterile normal saline and spread it on the MRS medium plate containing 0.5% (mass percentage) calcium carbonate On, 37 ℃ static culture 48h.

[0054] 2. After completing step 1, pick a single colony with a calcium-dissolving circle from the MRS medium plate, and repeatedly streak and purify it.

[0055] 3. Screen the bacterial strains purified in step 2, and use the cup and saucer method to screen the bacterial strains with antibacterial activity with Lactobacillus plantarum PL2 as the indicator bacterium, to DPPH , OH, O 2 - · The clearance rate of the index was further screened to obtain a strain with high antioxidant activity, which was named strain b-2.

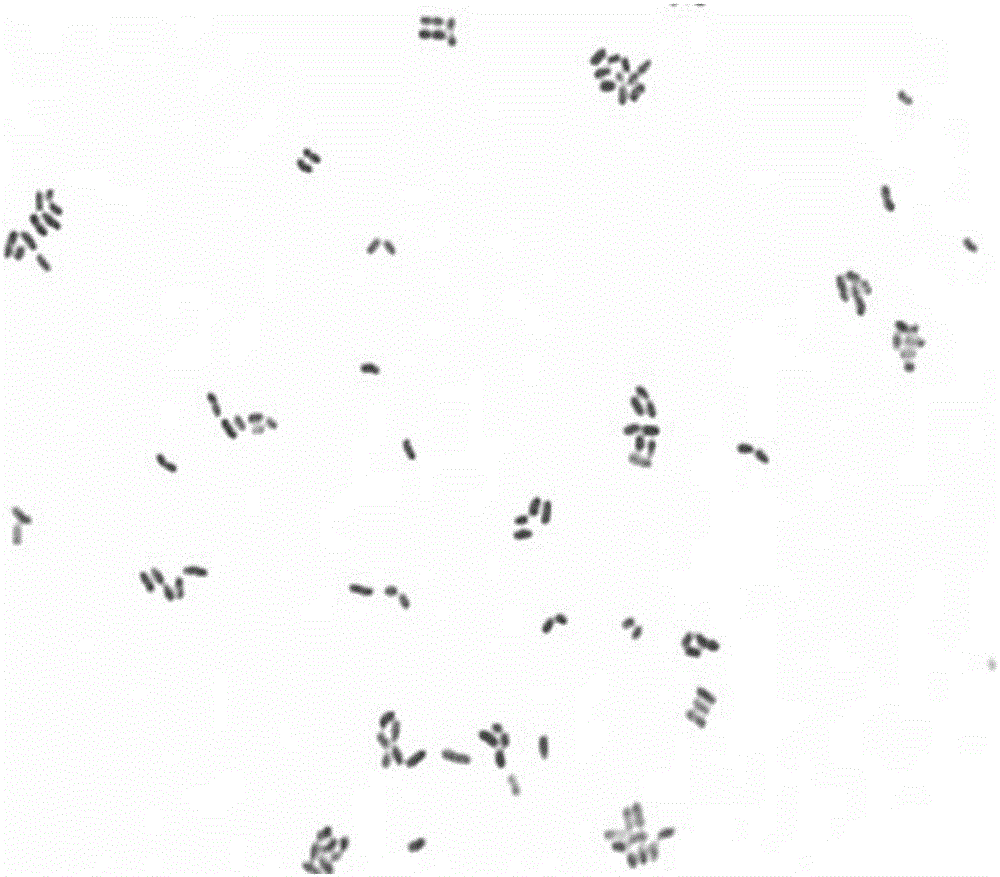

[0056] 2. Morphological identification and molecular identification o...

Embodiment 2

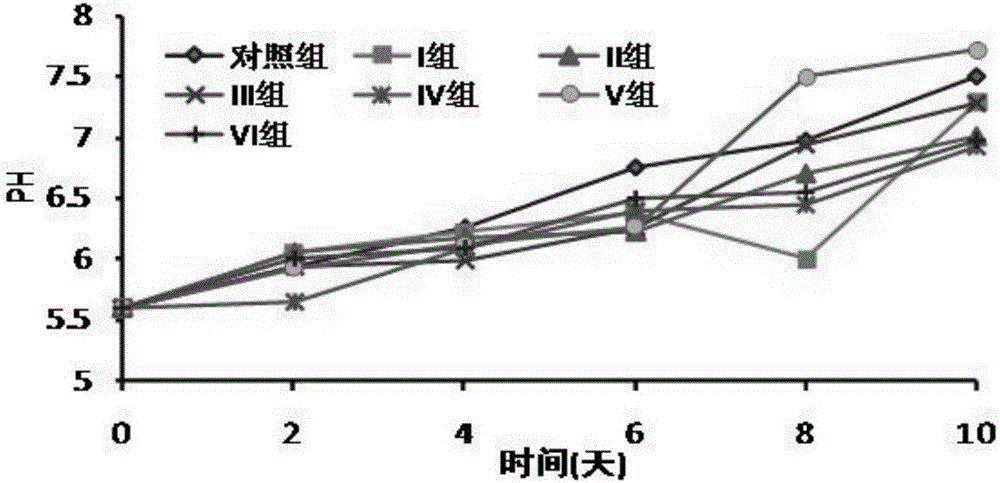

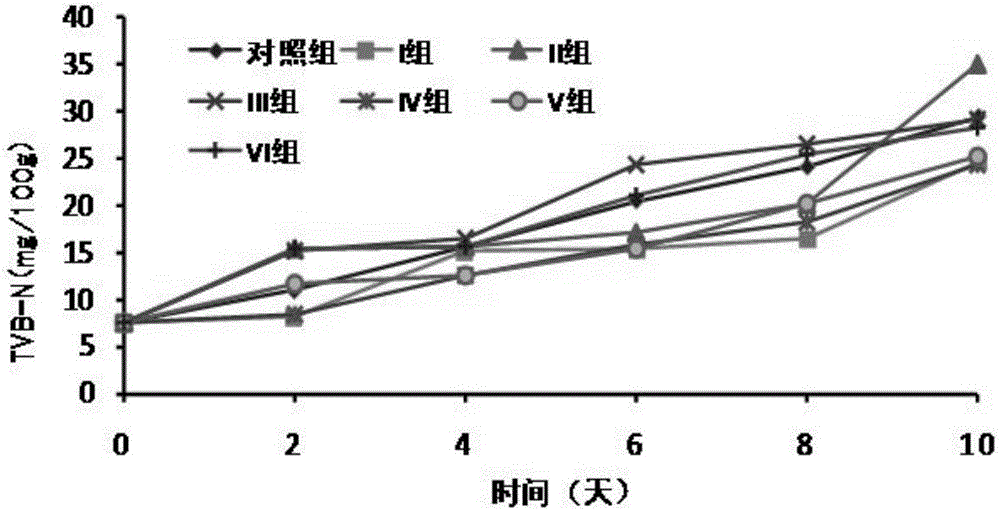

[0064] Embodiment 2, preparation and effect evaluation of natural composite antiseptic preservative

[0065] One, the preparation of Lactobacillus plantarum b-2 bacteriocin

[0066] 1, the plantaractobacillus b-2 that embodiment 1 obtains is inoculated in the MRS medium (final concentration is 10 7 CFU / ml), culture at 37°C for 30 hours, then centrifuge at 10,000 r / min for 10 minutes at 4°C, and collect the supernatant.

[0067] 2. Take the supernatant obtained in step 1, add ammonium sulfate powder while stirring at room temperature until reaching 70% saturation, then stand at 4°C for 2h, centrifuge at 12000rpm at 4°C for 10min, and collect the precipitate.

[0068] 3. Take the precipitate obtained in step 2, redissolve it in sterile water, desalt it with an ultrafiltration membrane with a pore size of 3500 Da, and then dry it in a freeze-vacuum dryer to obtain a powder, which is bacteriocin.

[0069] About 3.0 g of bacteriocin was obtained per 1 L of the culture system of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com