Multi-element circulating straw biogas fermentation system

A biogas fermentation and circulation technology, applied in solid-phase fermentation bioreactor, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem of low substrate degradation rate and biogas yield , fermentation system temperature instability, restricting the development of new energy technology and other issues, to achieve the effect of improving fermentation efficiency and biogas production rate, good practical value and promotion significance, good economic benefits and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

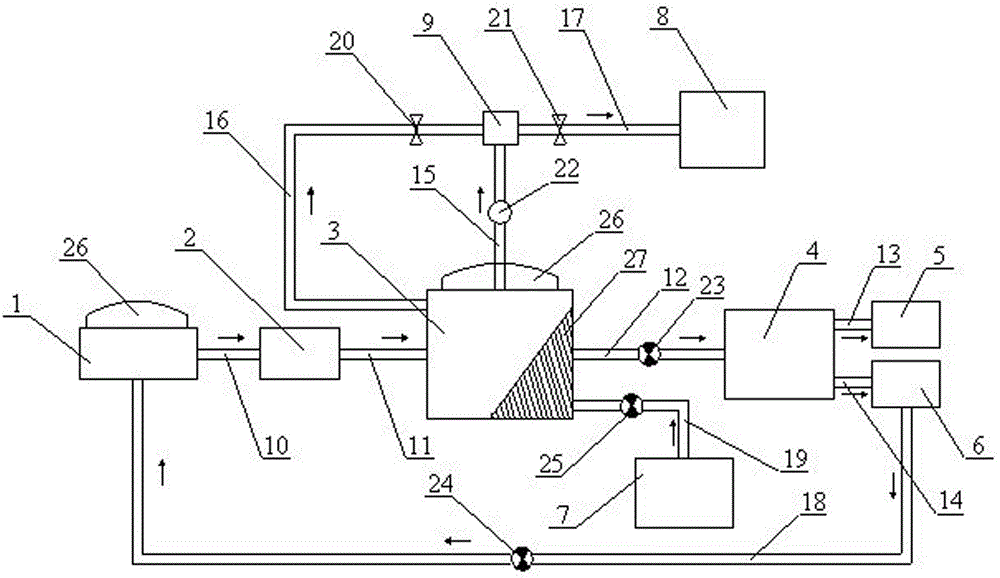

[0009] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

[0010] Such as figure 1 As shown, the present invention provides a multi-component circulation type straw biogas fermentation system, including a straw pretreatment pond 1, a stirring pond 2, a fermentation pond 3, a solid-liquid separation pond 4, a first biogas residue storage pond 5, a second biogas residue The storage pool 6, the replenishment pool 7, the gas storage tank 8, the three-way valve 9, the straw pretreatment pool 1 and the stirring pool 2 are connected through the first connecting pipe 10, and the stirring pool 2 and the fermentation pool 3 are connected through the second connecting pipe 11 The fermentation tank 3 is connected with the solid-liquid separation tank 4 through the third connecting pipe 12, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com