Hydrogen production and struvite recovery method for sludge by adopting FNA (free nitrous acid) reinforced microbial electrolysis

A microbial electrolysis and nitrite technology is applied in the field of using free nitrite to strengthen microbial electrolysis sludge for hydrogen production and recovery of struvite, which can solve the problem of low utilization rate of sludge organic matter, low recovery rate of high value-added nutrients, and low recovery rate of high value-added nutrients. Problems such as difficulty in breaking the wall of sludge flocs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

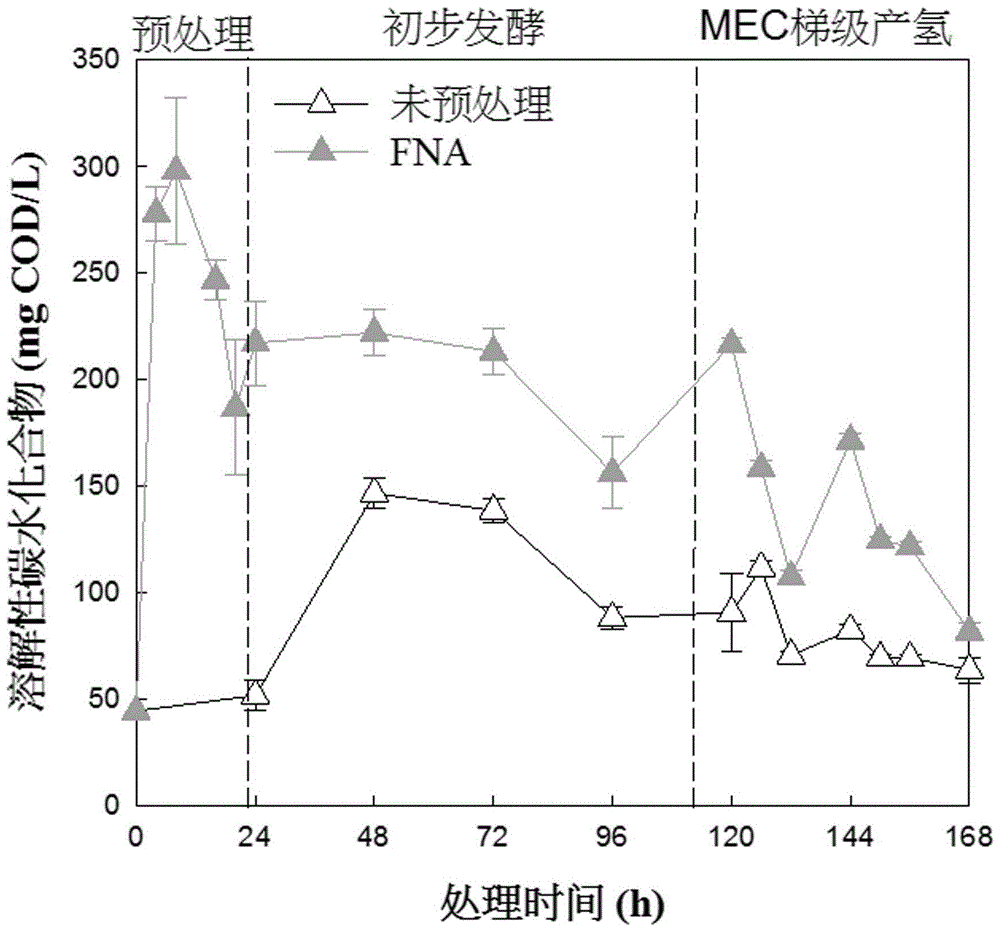

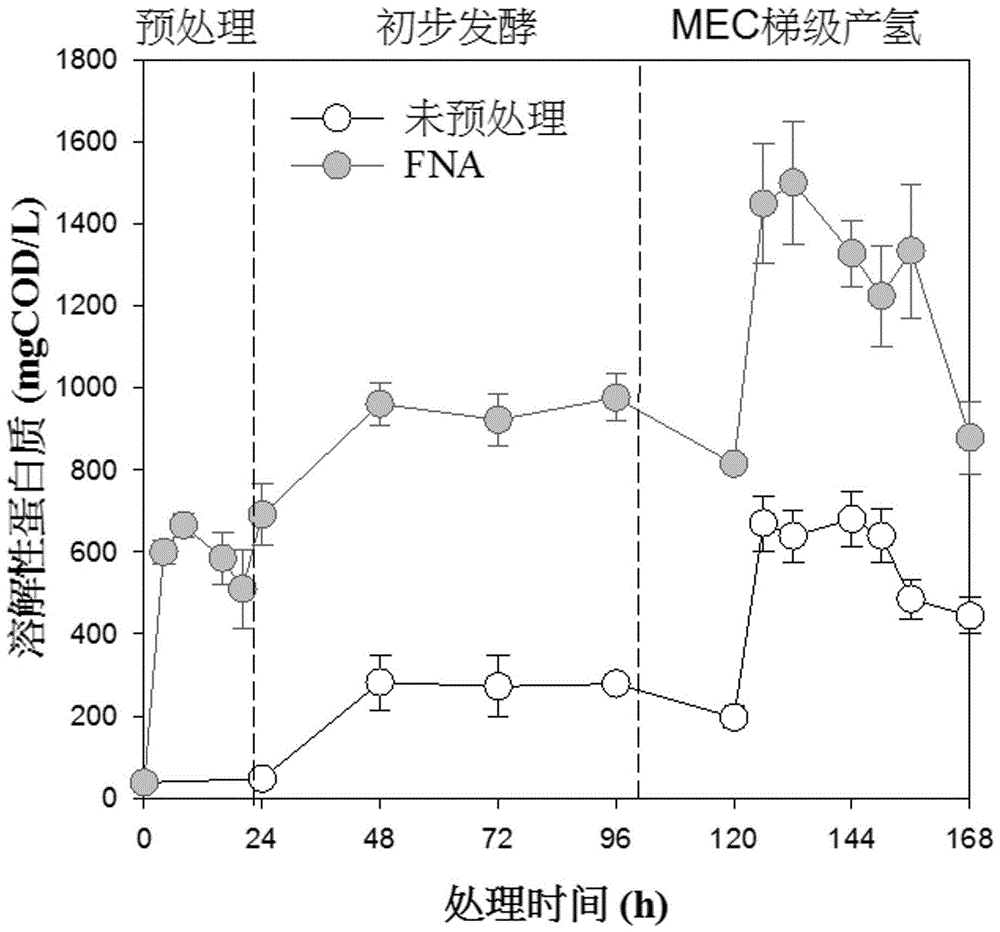

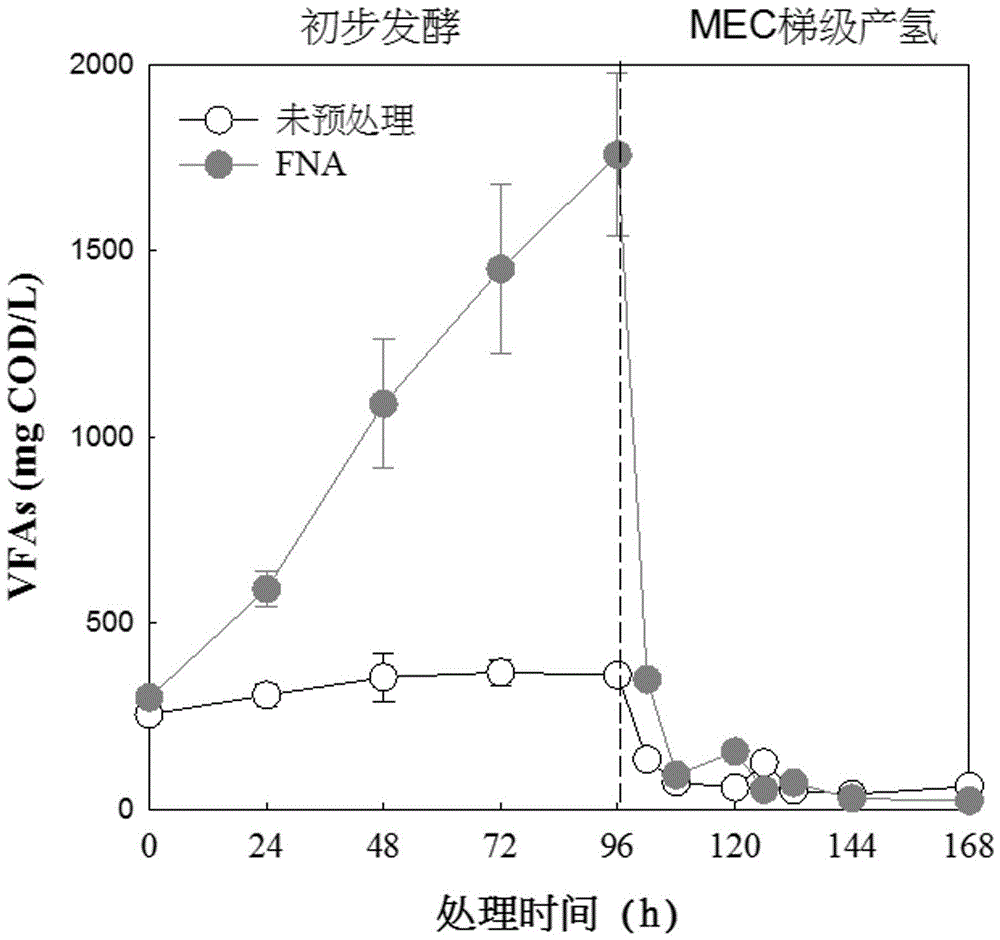

[0018] Specific implementation mode 1: In this implementation mode, free nitrite is used to strengthen the hydrogen production of microbial electrolytic sludge and recover struvite, specifically according to the following steps:

[0019] 1. Sludge pretreatment: Settling the remaining sludge naturally at a temperature of 4 °C, the settling time is 24 h ~ 30 h (optional 24 h, 26 h, 28 h, 30 h), and then drain the supernatant liquid to obtain sludge samples; prepare NaNO 2 Stock solution, so that the concentration of FNA in the reactor reaches 2.13 mgN / L, the rotation speed is 102 rpm / min ~108 rpm / min (102 rpm / min, 104 rpm / min, 106 rpm / min, 108 rpm / min can be selected), and the treatment is 24 h ;

[0020] 2. Preliminary anaerobic fermentation of sludge: After driving oxygen and nitrogen into the reaction bottle for 10 minutes, seal the reaction bottle and put it in an air bath shaker at 100 rpm / min~110rpm / min (100rpm / min, 102rpm / min, 104 rpm / min, 106rpm / min, 108rpm / min, 110rpm...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the pH should be adjusted to 5.5 ± 0.1 using 1.0M NaOH and HCl in step 1, and phosphate buffer solution is added to keep the pH. Others are the same as Embodiment 1. same.

specific Embodiment approach 3

[0025] Specific embodiment three: this embodiment is different from one of specific embodiments one to two in that: the VSS of sludge anaerobic fermentation in step two should be more than 10 g / L, and the sludge after FNA pretreatment should be 1: A ratio of 9 was added to the new inoculated sludge. Others are the same as one of the specific embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com