Method for purifying gallic acid production waste water through nanometer silica gel

A technology for producing gallic acid and wastewater, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, multi-stage water treatment, etc., to achieve the effects of simplified resource recycling, low economic cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

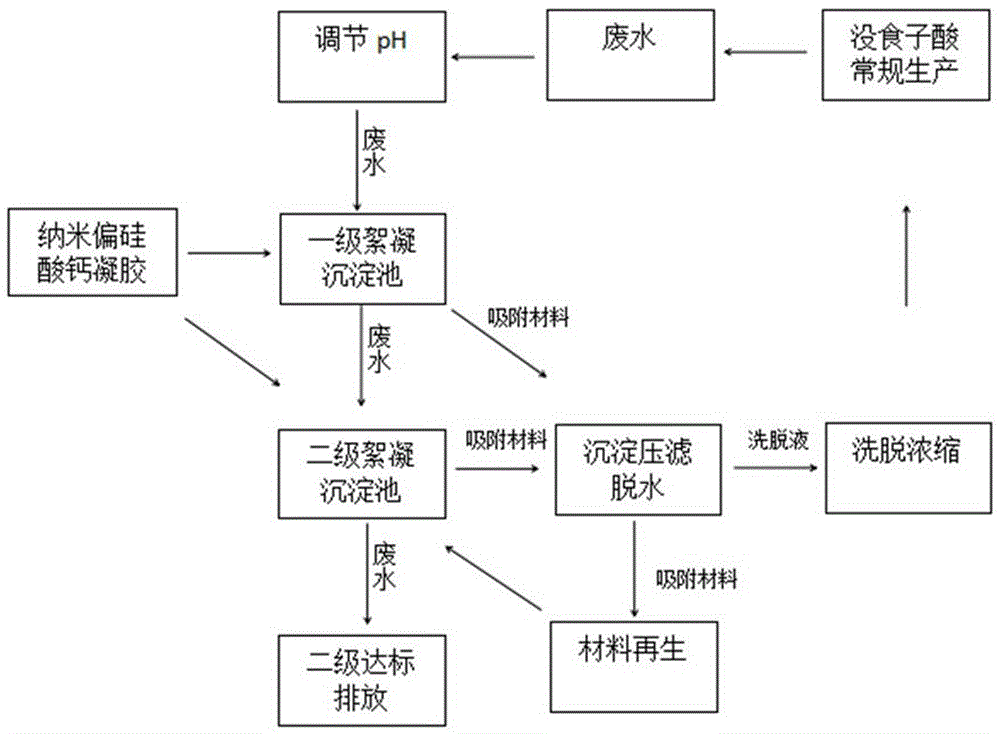

Image

Examples

Embodiment 1

[0022] Example 1: Processing wastewater of gallnut treated with the maximum dosage of nano-silica gel

[0023] pH value 1.41, gallic acid content 1.46%, salt content 10.21%, COD CrThe 28086 mg / L gall processing wastewater was adjusted to pH 10 with lime milk with a concentration of 15% by mass in the storage tank, and then introduced into the first-level flocculation sedimentation tank. Add calcium metasilicate nanogel at a dosage of 50 g / L to the first-level flocculation tank, stir and adsorb for 4 hours, and then precipitate for 2 hours. The wastewater treated in the primary tank flows into the secondary flocculation tank, and the amount of calcium metasilicate nanogel added is 50g / L, stirred and adsorbed for 3 hours, and then precipitated for 2 hours. The gallic acid removal rate of the wastewater purified by this secondary flocculation tank is 93.57%, and the wastewater COD = 88.75mg / L.

[0024] The nano-silica gel precipitate in the primary or secondary flocculation sed...

Embodiment 2

[0026] Example 2: The minimum dosage of nano-silica gel to treat the processing wastewater of Galla japonica

[0027] pH value 1.41, gallic acid content 1.46%, salt content 10.21%, COD Cr The 28086 mg / L gall processing wastewater was adjusted to pH 10 with lime milk with a concentration of 15% by mass in the storage tank, and then introduced into the first-level flocculation sedimentation tank. Add calcium metasilicate nanogel at a dosage of 40 g / L to the primary flocculation tank, stir and adsorb for 4 hours, and then precipitate for 2 hours. The wastewater treated in the primary tank flows into the secondary flocculation tank, and the amount of calcium metasilicate nanogel added is 40g / L, stirred and adsorbed for 3 hours, and then precipitated for 2 hours. The gallic acid removal rate of the wastewater purified by this secondary flocculation tank is 90.24%, and the wastewater COD = 94.46mg / L.

[0028] The nano-silica gel precipitate in the primary or secondary flocculation...

Embodiment 3

[0030] Example 3: Optimum dosage of nano-silica gel to treat processing wastewater of gallnut

[0031] pH value 1.41, gallic acid content 1.46%, salt content 10.21%, COD Cr The 28086 mg / L gall processing wastewater was adjusted to pH 10 with lime milk with a concentration of 15% by mass in the storage tank, and then introduced into the first-level flocculation sedimentation tank. Add calcium metasilicate nanogel at a dosage of 50 g / L to the first-level flocculation tank, stir and adsorb for 4 hours, and then precipitate for 2 hours. The wastewater treated in the primary tank flows into the secondary flocculation tank, and the amount of calcium metasilicate nanogel added is 40g / L, stirred and adsorbed for 3 hours, and then precipitated for 2 hours. The wastewater purified by this secondary flocculation tank has a gallic acid removal rate of 92.26% and wastewater COD = 90.05mg / L.

[0032] The nano-silica gel precipitate in the primary or secondary flocculation sedimentation ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com