Automatic retractable belt machine

An automatic telescopic and belt conveyor technology, applied in conveyors, transportation and packaging, can solve the problems of high operating costs and low transfer efficiency, and achieve the effect of increasing the storage space, saving labor, and being fast and convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

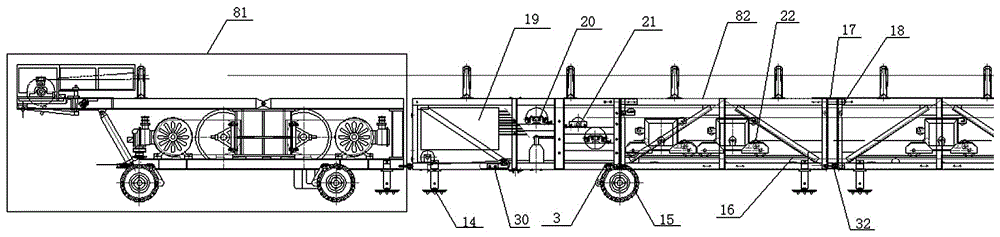

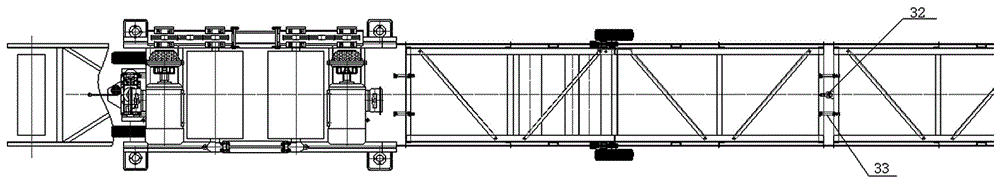

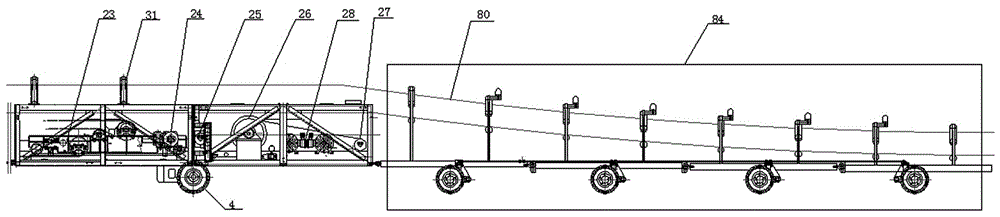

[0052] Such as figure 1 , 2 , shown in 3, 4, a kind of automatic retractable belt machine, comprises steel truss train, transition train 84, telescopic train 85, material receiving navigation tractor 83 and adhesive tape 80, steel truss train, transition train 84, telescopic train 85, receiving The material navigation tractor 83 is articulated successively by the articulation seat 32 and the compression spring device 33, and the compression spring device 33 is symmetrically arranged on the left and right sides of the articulation seat 32; Between several steel truss gun carriages 82 and between the steel truss gun carriage 82 at the end and the navigation nose 81, hinge seats 32 and compression spring devices 33 are used to hinge, and the compression spring devices 33 are symmetrically arranged on the left and right sides of the hinge seat 32 , the front end of the navigation nose 81 and the tail end of the receiving navigation tractor 83 are respectively equipped with an unm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com