Protection door opening/closing device of tool machine

A technology of opening and closing devices and protective doors, which is applied in the direction of positioning devices, manufacturing tools, metal processing machinery parts, etc., which can solve the problem that the tool changing mechanism 112 cannot move smoothly, hinders the movement of the tool changing mechanism 112, and affects the smoothness of the tool changing operation and other problems, to achieve the effect of reducing production cost and tool changing time, and saving waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make your review committee members have a further understanding of the present invention, the preferred embodiments are hereby given in conjunction with the drawings, and are described in detail as follows:

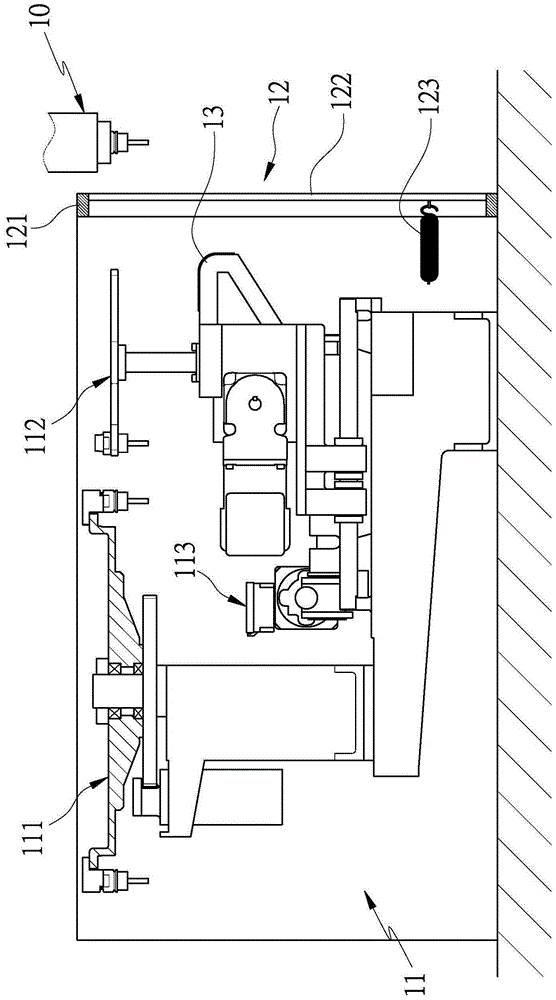

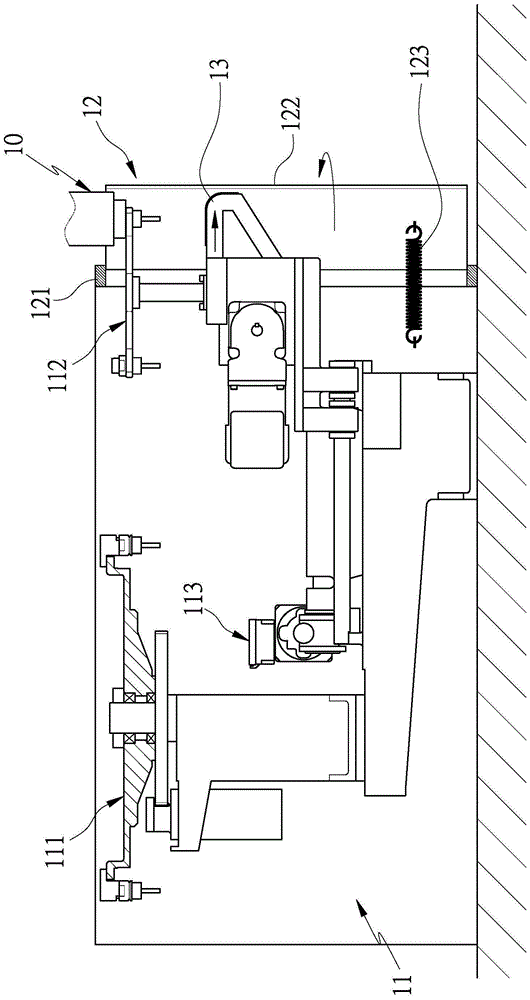

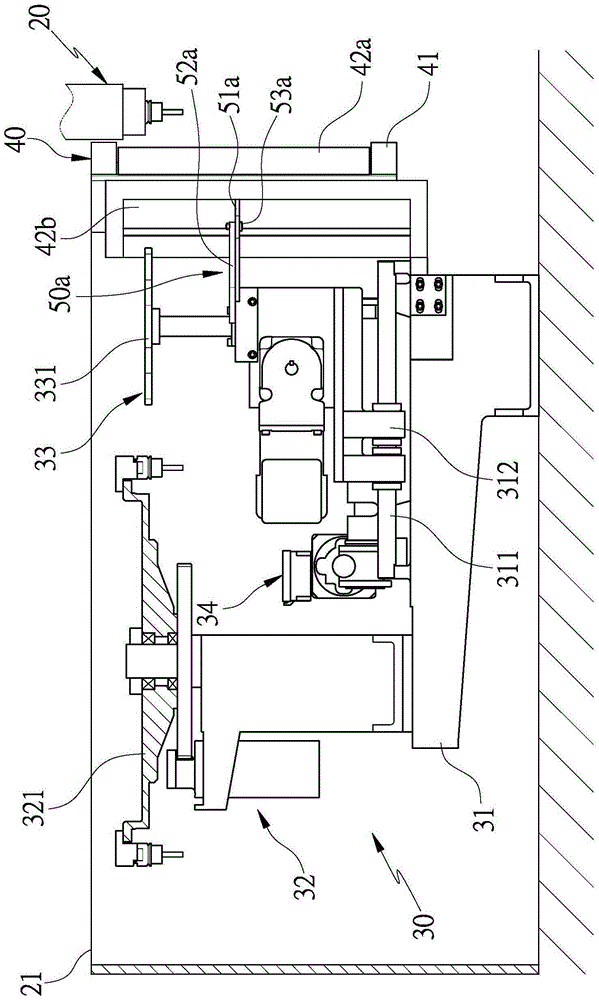

[0045] see image 3 , Figure 4 As shown, the protective door opening and closing device of the machine tool according to the first embodiment of the present invention is provided with a machining spindle 20 on the machine tool, and an accommodating space is surrounded by a plate 21 at the side of the machining spindle 20 , a tool changing device is installed in the accommodation space, and a driving source is used to drive the tool changing device to move to the tool changing position, so as to perform the tool changing operation of the machining spindle 20, wherein the tool changing device can be without Arm type or knife arm type, the armless tool changer is only equipped with a tool magazine, and the tool magazine of the tool changer is directly dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com