Spectacle frame drilling machine capable of achieving multi-angle rotation

A technology of eyeglass frame and drilling machine, applied in boring/drilling, eyeglasses/goggles, eyeglasses/safety goggles and other directions, can solve the problems of inconvenient adjustment of the position of the eyeglass frame and no movement adjustment function, etc. Ingenious, easy to adjust, easy to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

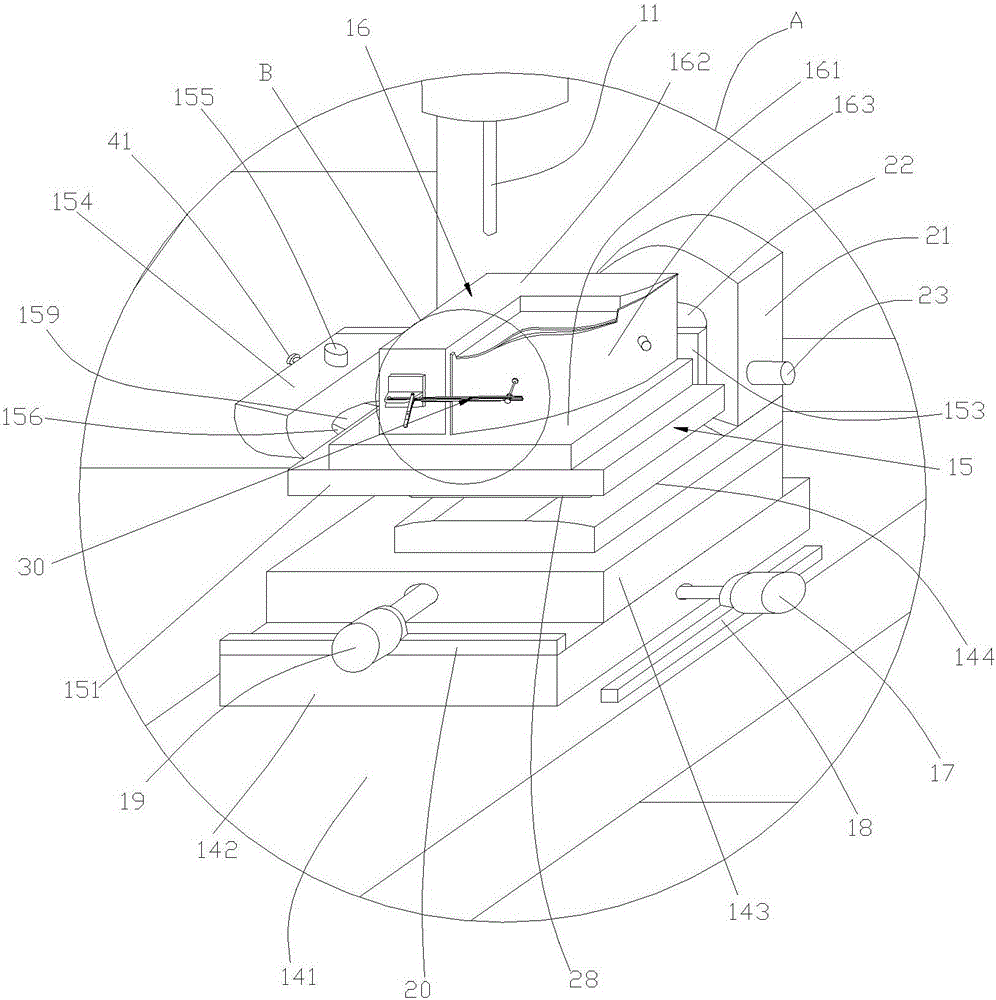

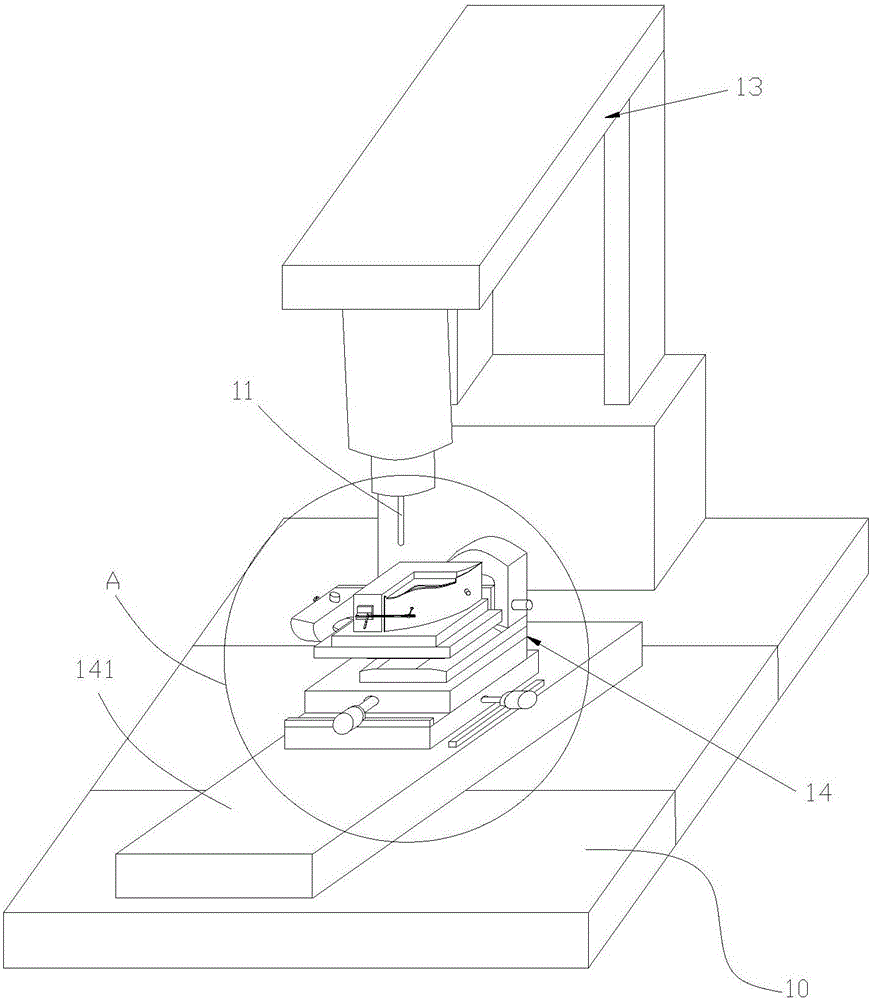

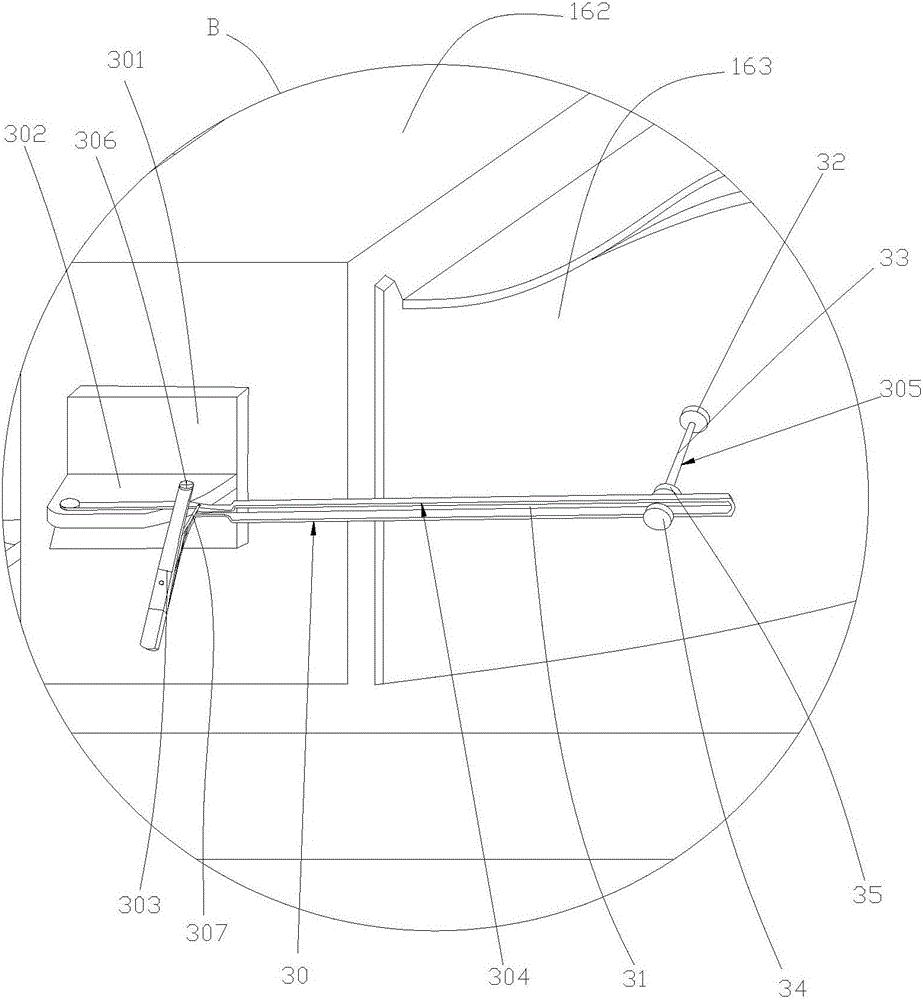

[0017] refer to figure 1 A drilling machine for eyeglass frames that can rotate at multiple angles, including a base 10, a drill bit 11 mounted on the base 10, and a fixing device 14 for fixing the eyeglass frame. The drill bit 11 is installed on the base 10 through the support frame 13 . Described drill bit 11 can move up and down and is installed on described support frame 13 (this moving up and down mode can adopt screw mandrel, motor drive, and this technology is prior art, or also can other those skilled in the art conventional up and down moving technology , will not be described in detail here). The fixing device 14 is installed below the drill bit 11 . The fixing device 14 includes a mounting plate 141 fixedly installed on the base 10, a left and right moving block 142 mounted on the mounting plate 141 movable left and right (the left and right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com