Magnetic micro-sphere, method for preparing same and application of magnetic micro-sphere to treating antibiotic wastewater

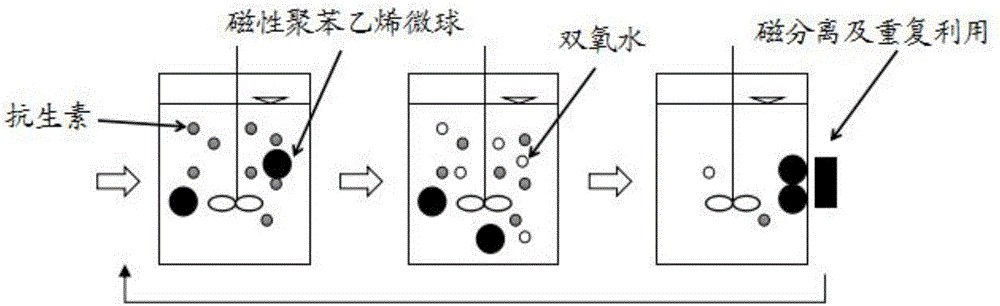

A technology of antibiotic wastewater and magnetic microspheres, which is applied in water/sewage treatment, natural water treatment, chemical instruments and methods, etc., can solve the problems of harsh preparation conditions, high comprehensive cost, and difficulty in mass production, and achieve good reuse effects , good durability, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The invention provides a kind of preparation method of magnetic microsphere, comprises the following steps:

[0039] (1) Adopt ethylenediamine and chloroacetic acid to modify chloromethyl polystyrene microspheres to obtain modified polystyrene microspheres;

[0040] Mixing ferric ammonium oxalate, surfactant, ion buffer and alcoholic organic solvent to obtain ferric ammonium oxalate solution;

[0041] (2) the modified polystyrene microspheres obtained by the step (1) are mixed with ferric ammonium oxalate solution, and pre-reaction is carried out under the condition of cutting off oxygen;

[0042] (3) performing a solvothermal reaction on the pre-reaction product obtained in the step (2) to obtain magnetic microspheres.

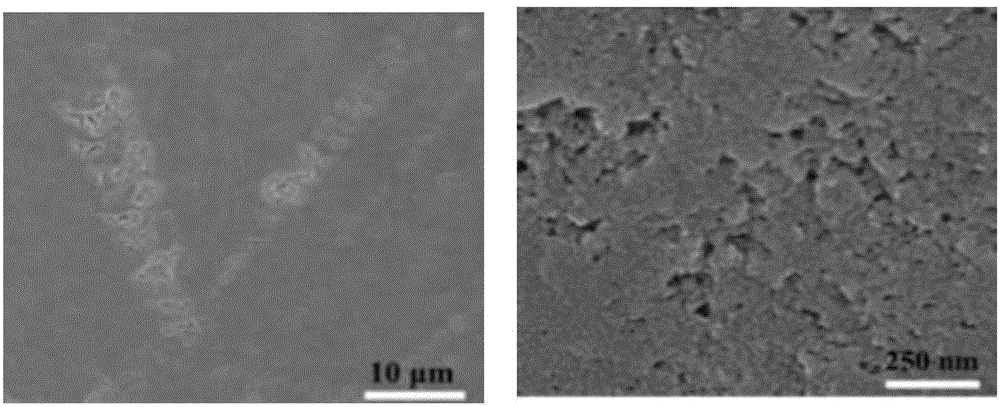

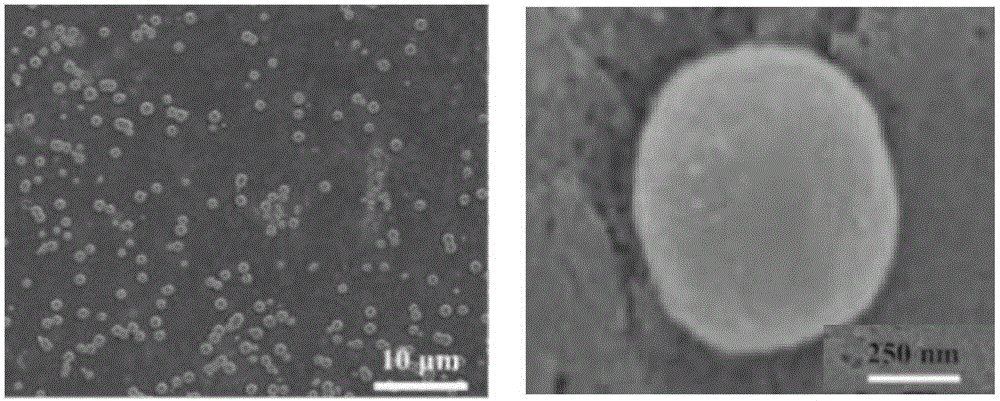

[0043] The invention adopts ethylenediamine and chloroacetic acid to modify the chloromethyl polystyrene microspheres to obtain the modified polystyrene microspheres. The invention adopts ethylenediamine and chloroacetic acid to modify the chlorometh...

Embodiment 1

[0086] (1) 2 g of commercially available chloromethyl polystyrene microspheres (PSC, CAS NO 55844-94-5, with a particle size of about 1 mm and a density of about 1.05 g / cm 3 ) in 20mL 1,4-dioxane for 2h, and then mixed with alkaline solution (2.5g sodium hydroxide, 0.1g phase transfer catalyst tetrabutylammonium bromide and 20mL water) and 25mL ethylene dioxane Mix the amines, heat in a water bath at 80-85°C, stir and react at 60rpm for 6h, filter the material obtained after the reaction, wash with water and methanol, and vacuum-dry for 4 days at a vacuum degree of 0.1MPa and 25°C , to obtain the precursor of modified polystyrene microspheres; 2.52g chloroacetic acid was neutralized with saturated sodium carbonate solution, and then mixed with alkaline solution (2.5g sodium hydroxide, 0.1g phase transfer catalyst tetrabutylammonium bromide and 20mL mixed solution of water) mixed with the obtained modified polystyrene microsphere precursor, heated in a water bath at 80-85° C., ...

Embodiment 2

[0093] With 100mg / L tetracycline aqueous solution as the antibiotic wastewater to be treated, the adsorption performance of the magnetic microspheres provided by the invention is verified, comprising the following steps:

[0094] The pH value of the tetracycline aqueous solution was adjusted to 6.5, based on the volume of the tetracycline aqueous solution, 2 g / L of the magnetic microspheres prepared in Example 1 were added, and the adsorption reaction was carried out at normal temperature and pressure, and the stirring rate was 60 rpm for 12 hours.

[0095] Sampling and analysis in the adsorption process, the results are as follows Figure 5 shown. Depend on Figure 5 From the curve shown in , it can be seen that the magnetic microspheres of the present invention have a certain adsorption performance for tetracycline, and 30% of tetracycline can be adsorbed within 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com