Making method of potato and coarse cereal cakes

A technology for potatoes and miscellaneous grains, which can be applied to dough processing, baking, baked foods with modified ingredients, etc., and can solve problems such as single structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

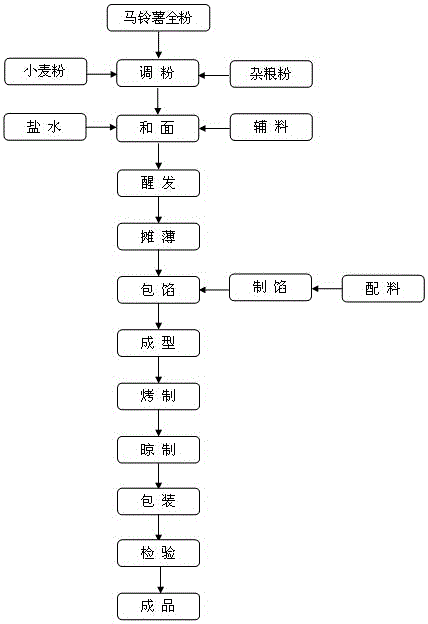

Image

Examples

Embodiment 1

[0021] Weigh 23.5kg of potato whole flour, 41.6kg of wheat flour, 10.3kg of corn flour, 5.2kg of soybean flour, 8.6kg of sweet potato flour, 3.4kg of lily flour, 2.1kg of highland barley flour, and 5.3kg of oat flour, mix and stir, and place the dough after mixing. Spray 5% salt water at 40°C into the machine and mix the dough, and stir to form a dough; transfer to a proofing room with a temperature of 35°C and a humidity of 80% to proof for 30 minutes; after proofing is mature, move the dough to the dough machine, squeeze and knead for 30 minutes. ~40min, form a uniform and stable dough; flatten it and cut it into 100cm 2 The dough cakes are wrapped with pre-prepared fillings, transferred to a mold at 70°C for 30-40 minutes, and pressed into different shapes; sent to a baking box at about 200°C for 30 minutes, and then taken out and dried for 30 minutes for packaging. finished product.

Embodiment 2

[0023] Weigh out 25.5kg of potato whole flour, 47.3kg of wheat flour, 8.8kg of corn flour, 4.5kg of soybean flour, 6.2kg of sweet potato flour, 2.4kg of lily flour, 1.7kg of highland barley flour, and 3.6kg of oat flour, mix and stir, and place the dough after mixing. Spray 5% salt water at 40°C into the machine and mix the dough, and stir to form a dough; transfer to a proofing room with a temperature of 35°C and a humidity of 80% to proof for 30 minutes; after proofing is mature, move the dough to the dough machine, squeeze and knead for 30 minutes. ~40min, form a uniform and stable dough; flatten it and cut it into 100cm 2 The dough cakes are wrapped with pre-prepared fillings, transferred to a mold at 70°C for 30-40 minutes, and pressed into different shapes; sent to a baking box at about 200°C for 30 minutes, and then taken out and dried for 30 minutes for packaging. finished product.

Embodiment 3

[0025] Weigh out 24.2kg of potato whole flour, 53.5kg of wheat flour, 7.0kg of corn flour, 3.8kg of soybean flour, 4.1kg of sweet potato flour, 2.0kg of lily flour, 1.4kg of highland barley flour, and 4.0kg of oat flour, mix and stir, and place the dough after mixing. Spray 5% salt water at 40°C into the machine and mix the dough, and stir to form a dough; transfer to a proofing room with a temperature of 35°C and a humidity of 80% to proof for 30 minutes; after proofing is mature, move the dough to the dough machine, squeeze and knead for 30 minutes. ~40min, form a uniform and stable dough; flatten it and cut it into 100cm 2 The dough cakes are wrapped with pre-prepared fillings, transferred to a mold at 70°C for 30-40 minutes, and pressed into different shapes; sent to a baking box at about 200°C for 30 minutes, and then taken out and dried for 30 minutes for packaging. finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com