Equipment for carding or carding machines

A carding machine and carding machine technology, used in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of export and heat loss, and achieve the effect of reducing cooling effect and small deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

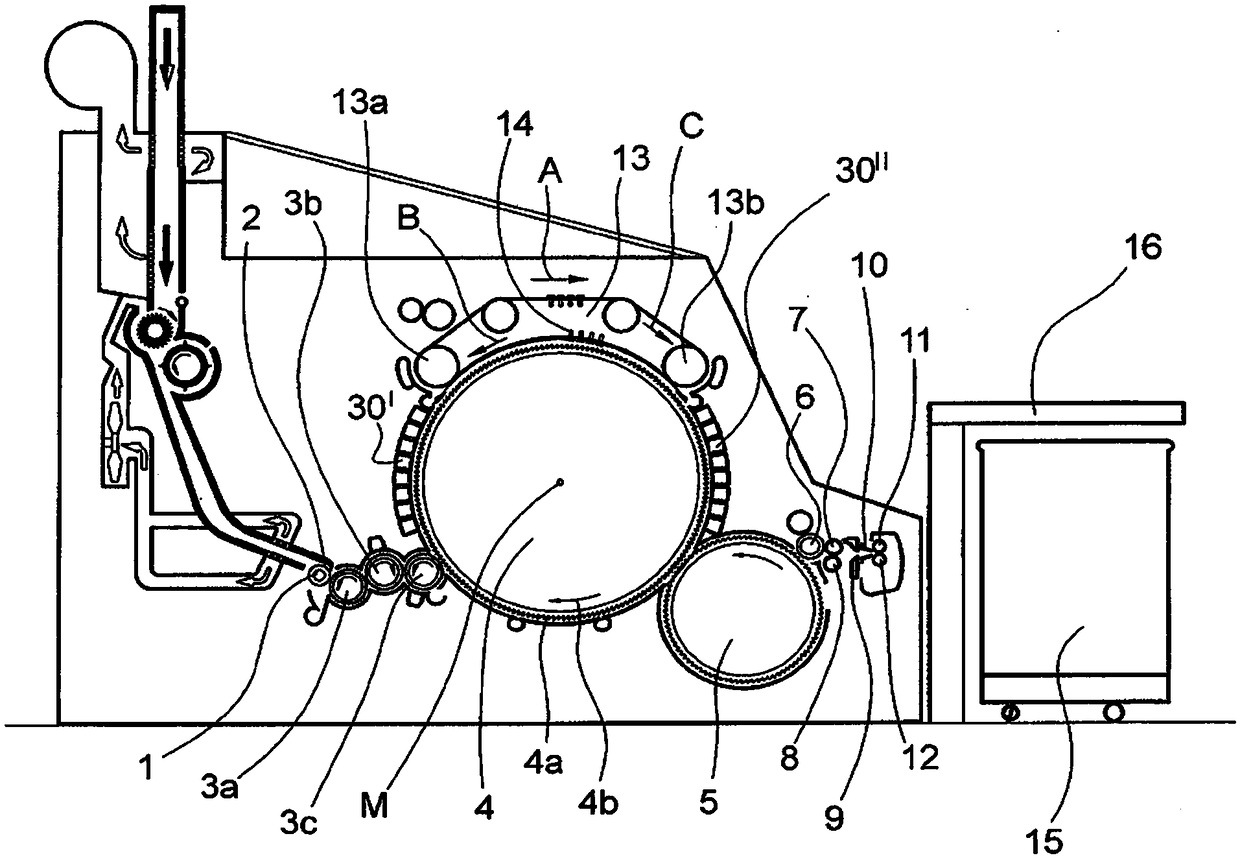

[0019] figure 1 Shown is a card, for example a Truetzschler card TC, which has a feed roller 1, a feed table 2, licker-in covers 3a, 3b, 3c, a cylinder 4, a doffer 5, a stripping Roller 6, pressure rollers 7, 8, web forming guide unit 9, fiber web collection bell mouth 10, separation rollers 11, 12, revolving cover plate 13 with cover plate turning guide rollers 13a, 13b and cover plate rod 14, bar Barrel 15 and coiler 16. The direction of rotation of the rollers is shown with curved arrows. Mark the middle point (axis) of cylinder 4 with M. 4a shows the card clothing and 4b shows the direction of rotation of the cylinder 4 . The direction of rotation of the revolving flat 13 in the carding position is marked with B and the return direction of the flat bar 14 with C, the functional elements with 30 ′, 30 ″ and the flat deflection guide rollers with 13 a and 13 b. Arrow A Mark the working direction.

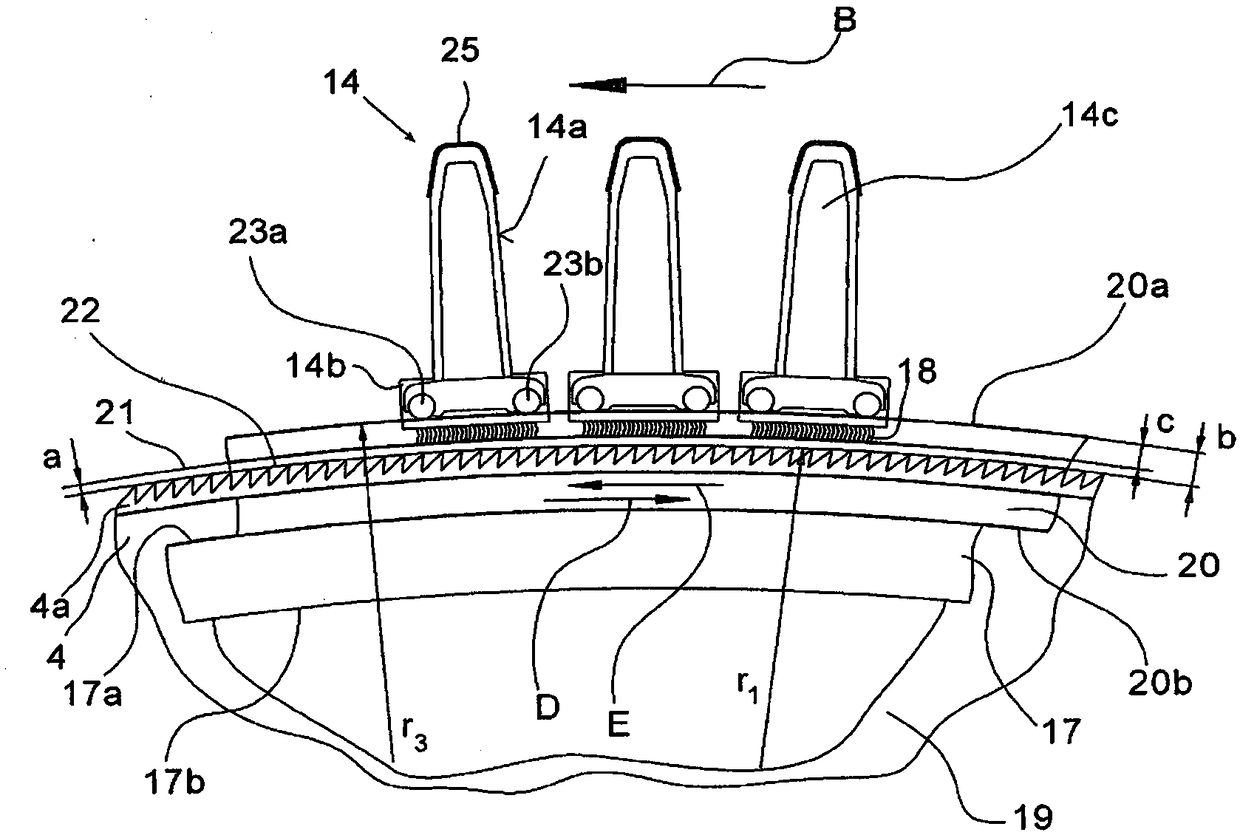

[0020] according to figure 2 , on each side of the carding machine the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com