Stretch-flange crack prediction method, stretch-flange crack prediction device, computer program, and recording medium

A prediction method, crack technology, applied in computer-aided design, calculation, design optimization/simulation, etc., can solve problems such as undisclosed, fracture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

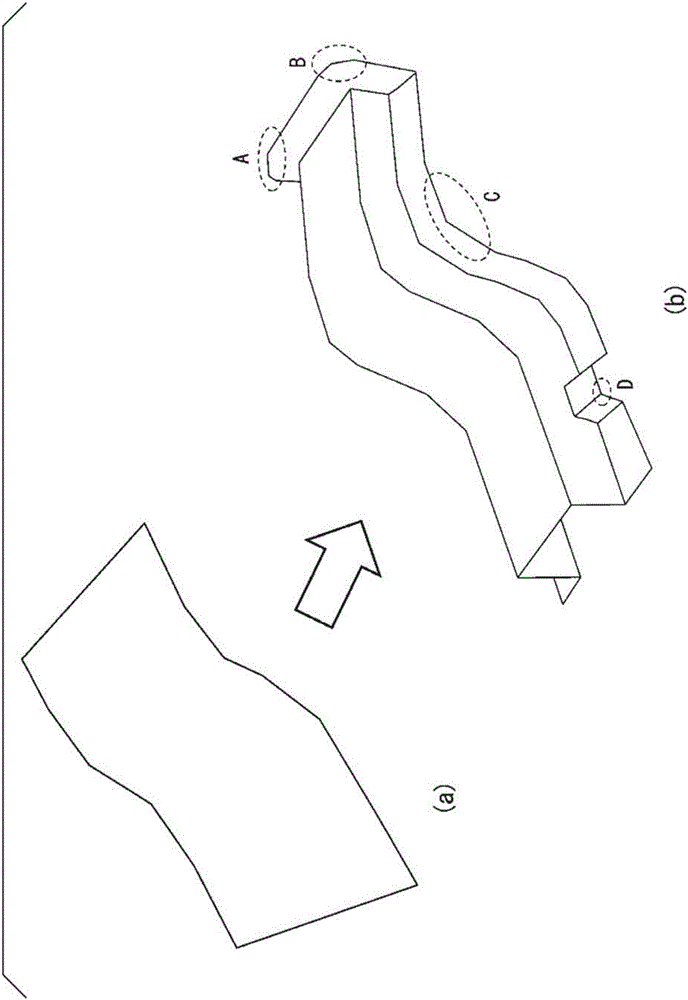

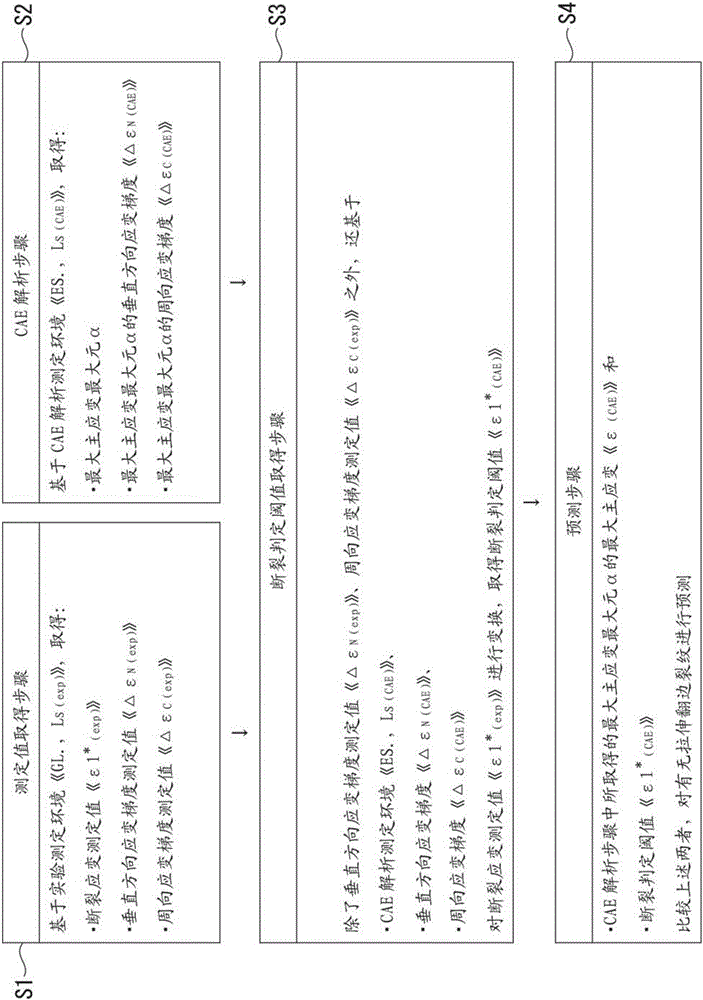

Method used

Image

Examples

no. 2 approach

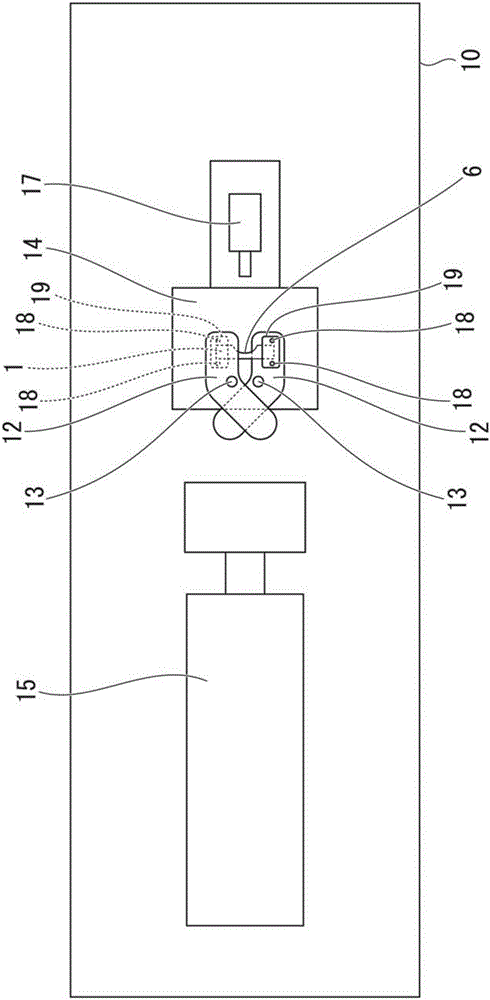

[0333] The stretch flanging crack prediction device 100 according to the second embodiment of the present invention implements the stretch flanging crack prediction method described in the above-mentioned first embodiment based on a built-in computer program. like Figure 17 As shown, the tensile flanging crack prediction device 100 includes: a measurement value acquisition unit 101 , a CAE analysis unit 102 , a fracture determination threshold acquisition unit 103 , and a prediction unit 104 .

[0334] In the measured value acquisition unit 101, based on the experimental measurement environment under the predetermined measurement length and the predetermined gradient evaluation length, the fracture strain measurement value, the vertical strain gradient measurement value, and the circumferential strain are respectively obtained for a plurality of plate test pieces. gradient measurements.

[0335] In the CAE analysis unit 102, the length is evaluated based on the specified ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com