A Computer Graphics Recognition Technology and Three-dimensional Modeling Method for the Mesostructure of Composite Materials

A computer identification and composite material technology, applied in the field of computer graphics recognition technology and three-dimensional modeling of composite material mesostructure, can solve the problems of difficult and unstable identification of material components, reduce boundary point extraction errors and save time , the effect of reducing the boundary fitting error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] A computer graphics recognition technology and a three-dimensional modeling method for a 2.5D composite material mesostructure, comprising the steps of:

[0056] Step 1: Using XCT technology to obtain slices of the internal structure of the 2.5D composite material. The length direction of the picture is the length direction of the material, and the out-of-plane direction of the picture is the axial direction of the weft yarn, such as figure 1 shown.

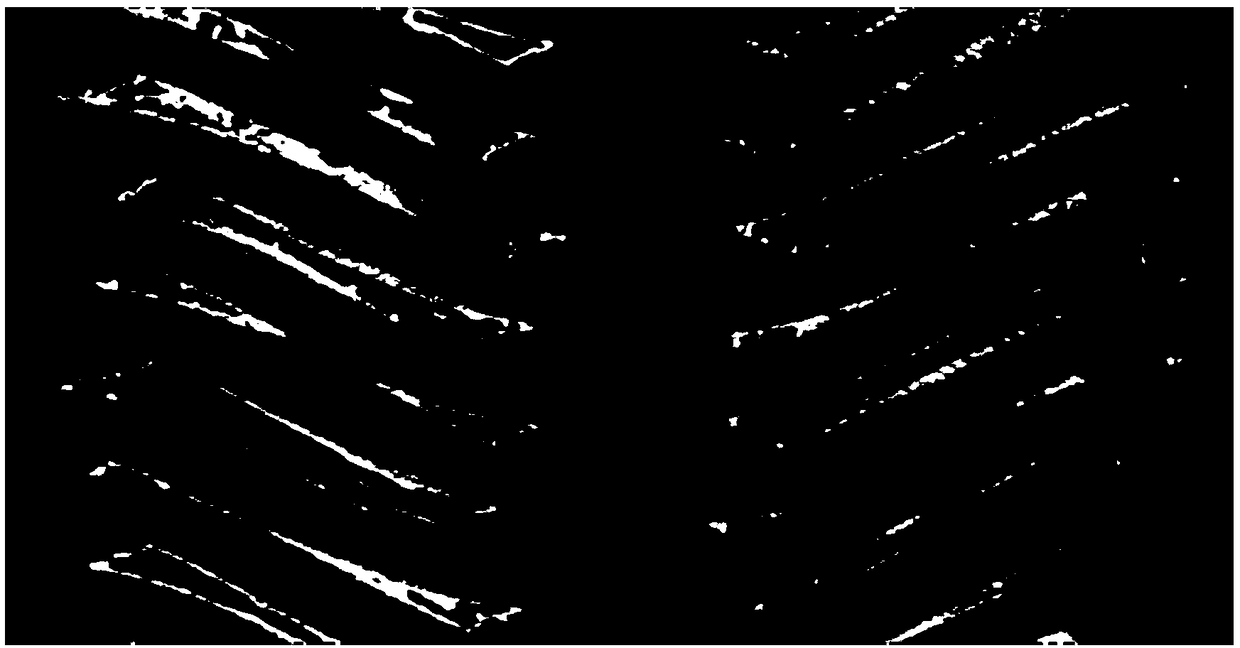

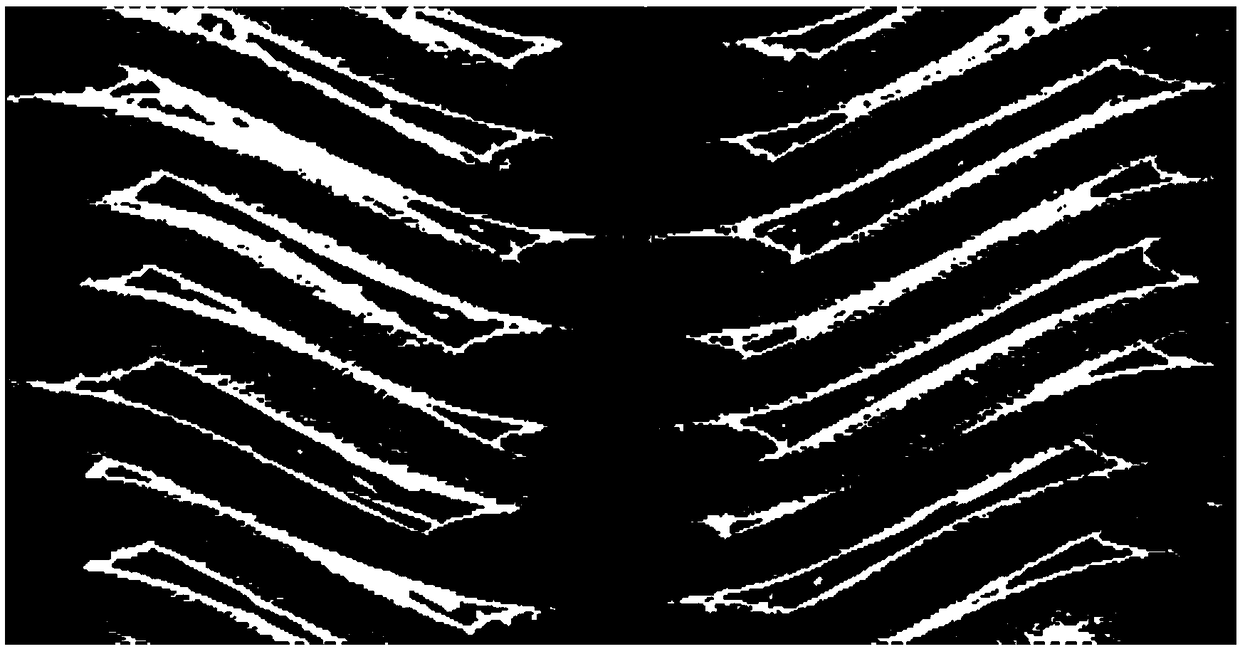

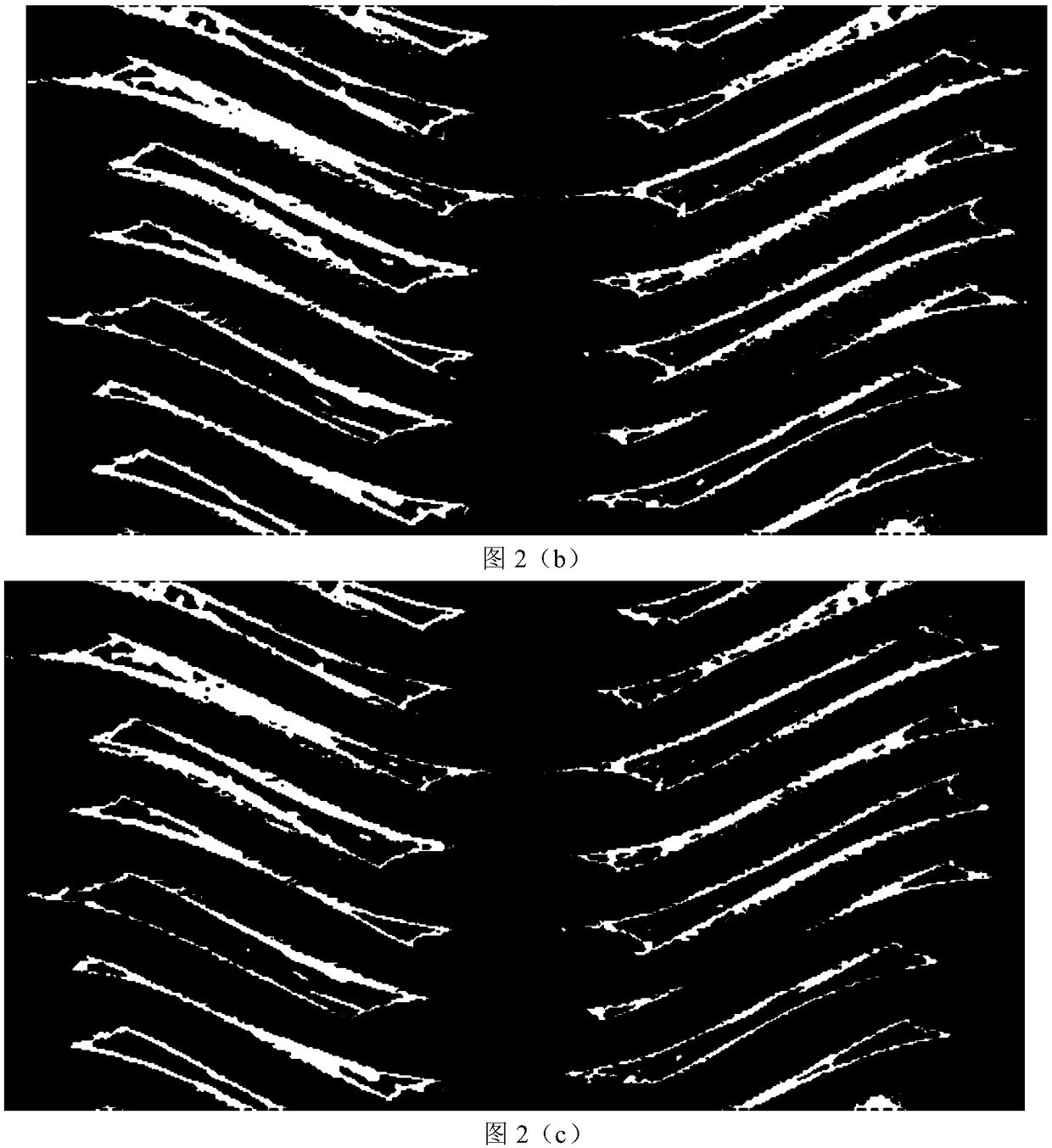

[0057] Step 2: Calculate the theoretical threshold m0 by using the outu threshold segmentation method, and compare the threshold segmentation effects adjacent to m. Such as figure 2 (a), (b), and (c) are binary images segmented by thresholds m0, m0+1, and m0+2 in turn, and the total number of corresponding independent small regions is 328, 196, and 228 in turn. It can be seen from the figure that after the threshold m0 is used for segmentation, there are more noise points in the picture, so the number of independent sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com