Pile turning machine having mud shoveling board

A mud scraper and pile turner technology, applied in the field of pile turners, can solve the problems of high power consumption and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

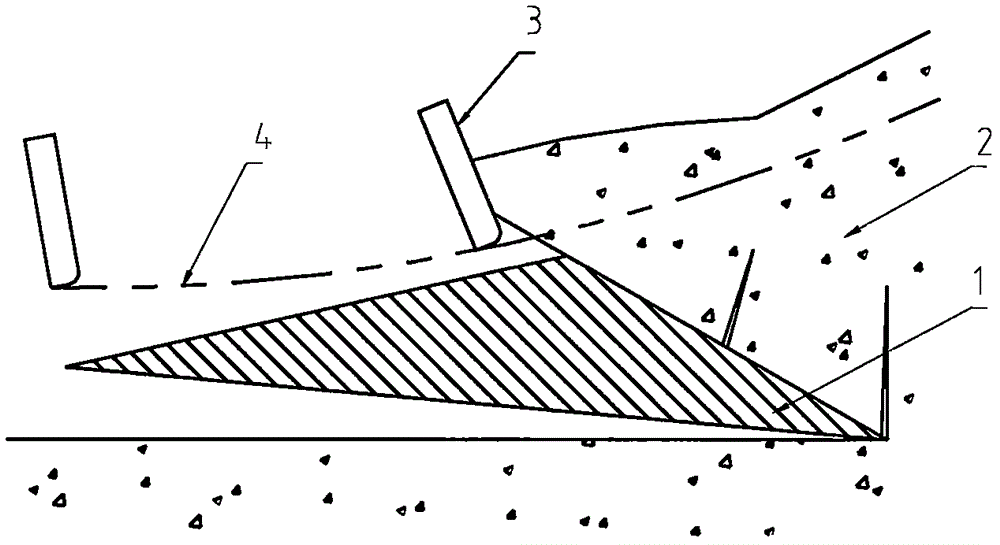

[0011] specific implementation plan

[0012] Below in conjunction with accompanying drawing, technical solution of the present invention is described in further detail:

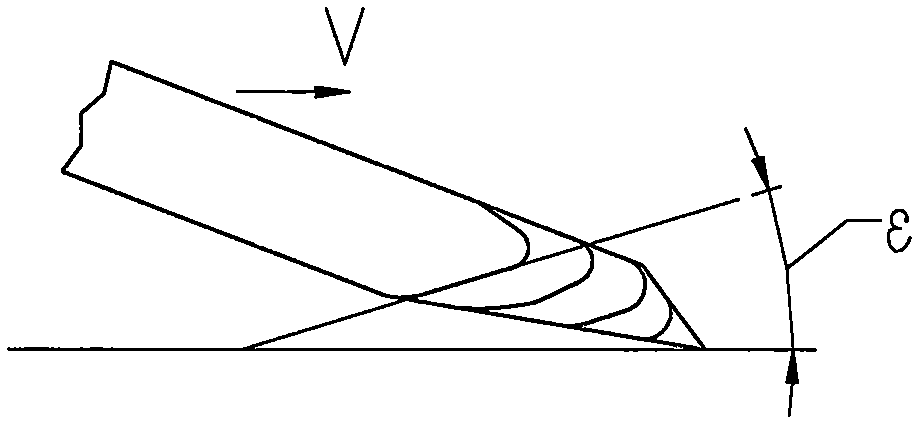

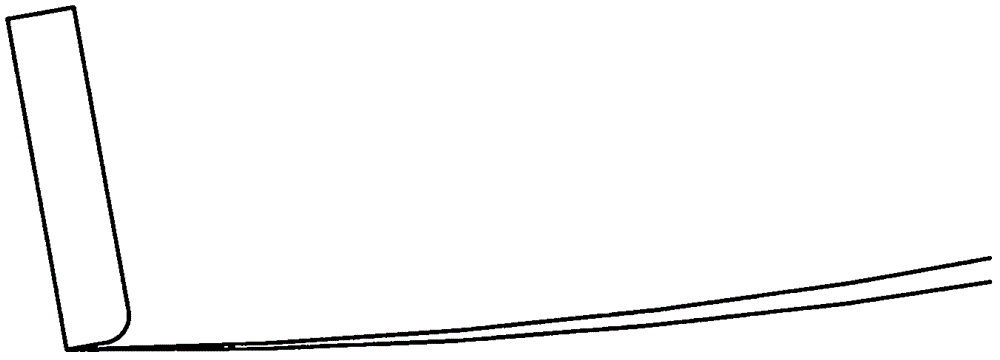

[0013] figure 1 Shown is the change process of the shape of the single metal plowshare blade when plowing hard loam in the article "Theory and Calculation of Soil Tillage Machinery" written by the former Soviet Union Sineakov, etc. The change shows that the cutter teeth of the turning machine will inevitably form rounded corners and negative back angles during the turning and throwing process. This phenomenon has also been confirmed from the actual wear and tear. , the formation of the negative relief angle further increases the thickness of the wiper pressure, resulting in the formation of a compacted layer on the surface. In the next cutting, the compacted layer is pulled by the pressure point around the edge and sinks around the cutter teeth, which further deteriorates the cutting process. condition.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com