Multi-segment slitting type paper shredder and paper shredding method

A paper shredder and paper shredding technology, applied in grain processing, etc., can solve the problems of high load power of the drive mechanism, affecting the life of the paper shredder, and high cost of the paper shredder, achieving the goals of reducing load power, low cost, and increasing life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

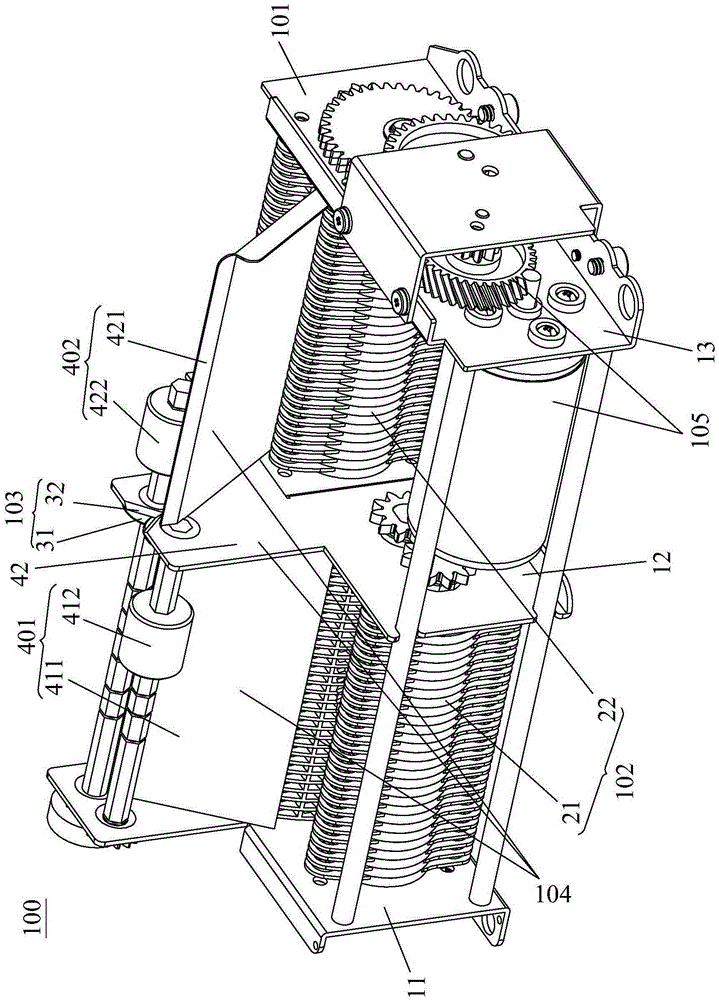

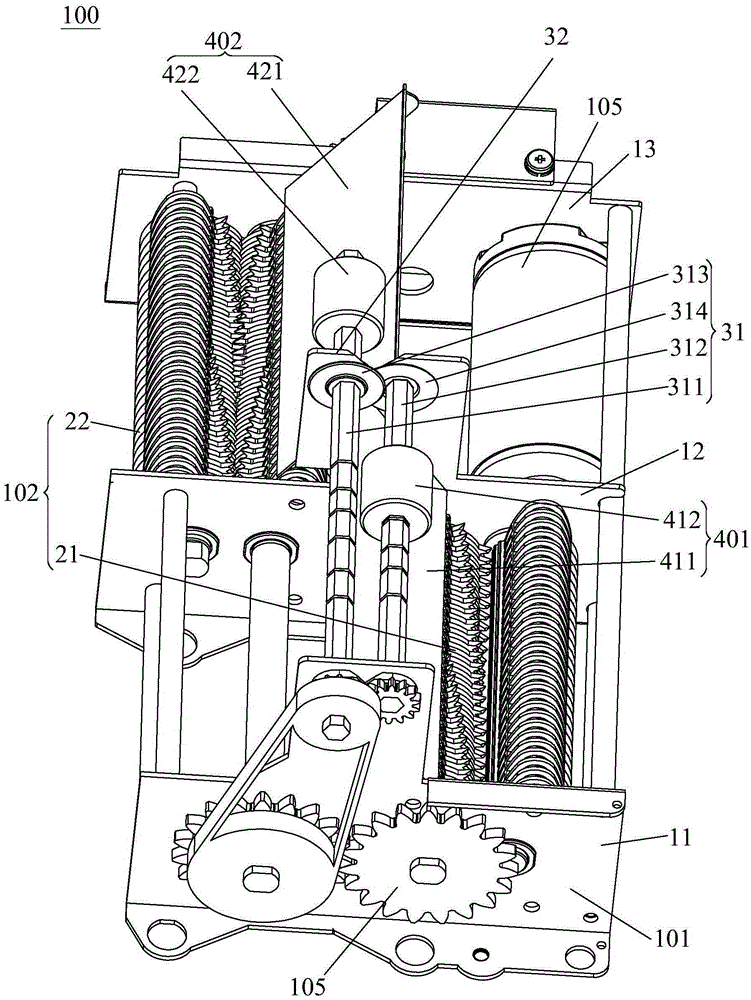

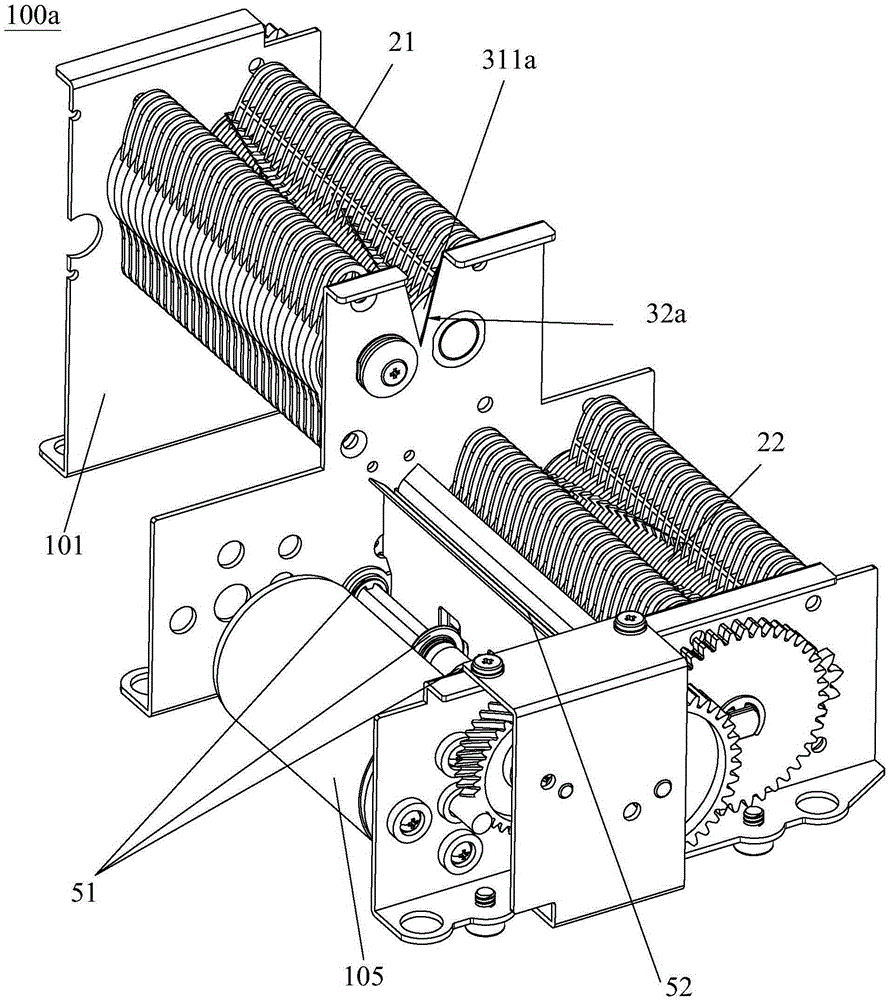

[0047] refer to Figure 1 to Figure 2 , the present invention discloses a multi-section shredder 100, including a frame 101, a shredding mechanism 102, a paper separating mechanism 103, a paper guiding mechanism 104 and a driving mechanism 105. In this embodiment, the shredding There are two mechanisms 102, namely the first shredding mechanism 21 and the second shredding mechanism 22, and the paper separating mechanism 103 includes a straight cutter group 31, and the straight cutter group 31 and the first shredder The mechanism 21 corresponds to the middle position of the second shredding mechanism 22 and divides the paper into two along its longitudinal direction. The paper guide mechanism 104 includes two guides corresponding to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com