Plastic liner for a composite pressure vessel

A technology of plastics and linings, applied in the direction of pressure vessels, container discharge methods, container structure manufacturing, etc., can solve problems such as hydrogen permeability problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

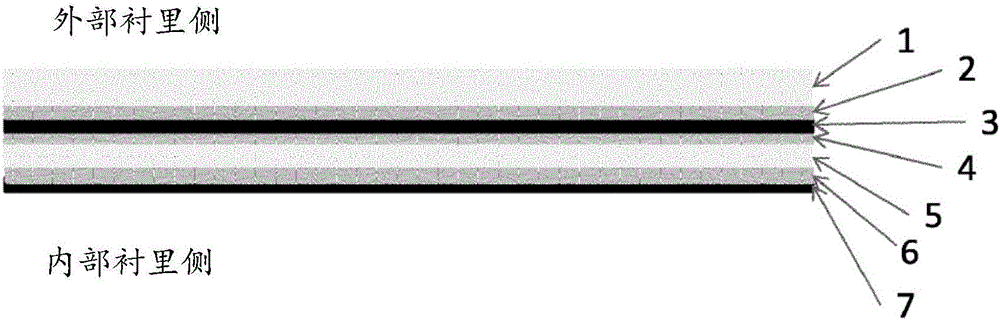

[0056] figure 1 is a schematic cross-sectional view of a multilayer structure of a plastic liner according to a first embodiment of the present invention. like figure 1 As shown, the plastic liner may comprise a PVDF-based inner layer 7, a first adhesive layer 6, an HDPE-based middle layer 5, a second adhesive layer 4, an EVOH-based barrier layer 3, a third adhesive layer 2 and HDPE-based outer layer1.

[0057] The multilayer structure combining PVDF layer and EVOH layer has the advantage of enhancing the barrier effect (ie reducing / eliminating the risk of gas permeation) while effectively protecting the liner from cracking effects due to foaming.

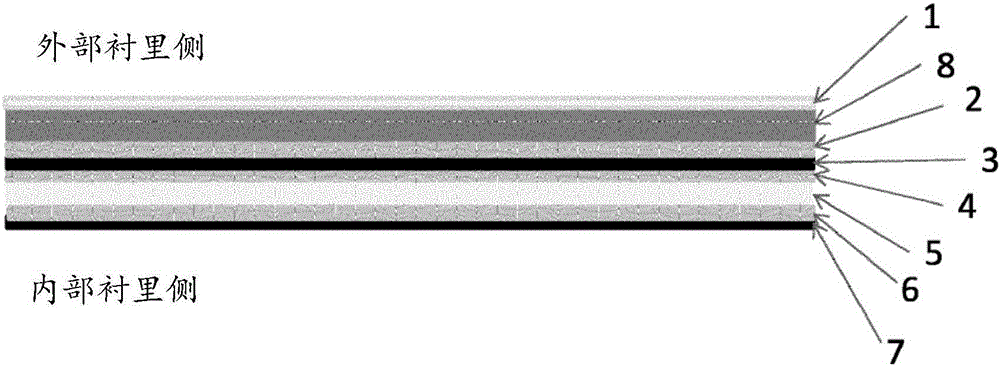

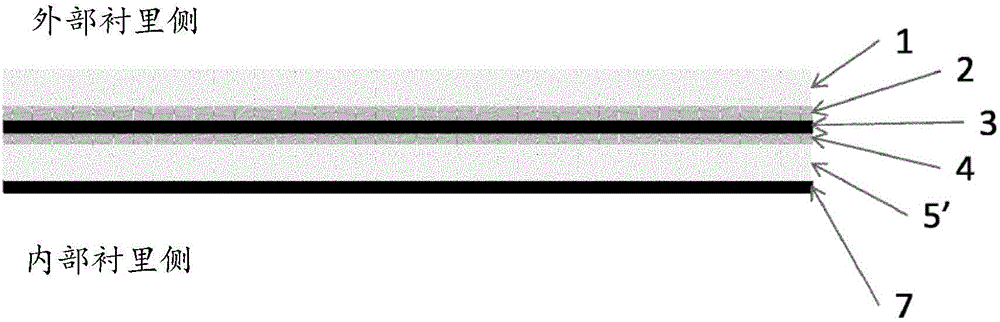

[0058] figure 2 is a schematic cross-sectional view of a multilayer structure of a plastic liner according to a second embodiment of the present invention. like figure 2 As shown, the plastic liner may comprise a PVDF-based inner layer 7, a first adhesive layer 6, an HDPE-based middle layer 5, a second adhesive layer 4, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com