Urea grease

A urea-based grease, aliphatic technology, used in lubricating compositions, thickeners, petroleum industry, etc., can solve problems such as poor acoustic characteristics, and achieve the effect of maintaining heat resistance and acoustic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

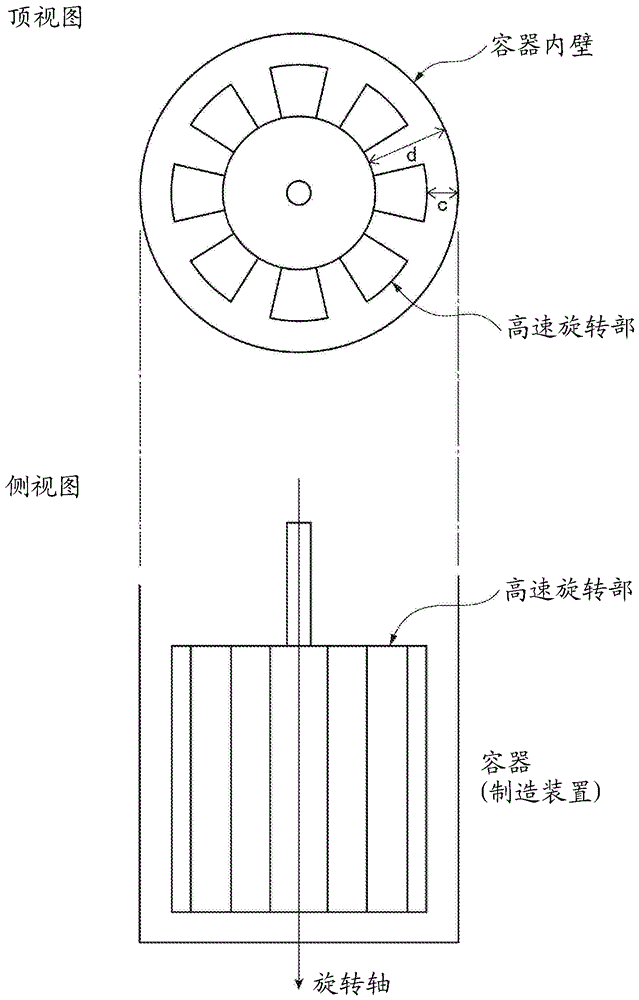

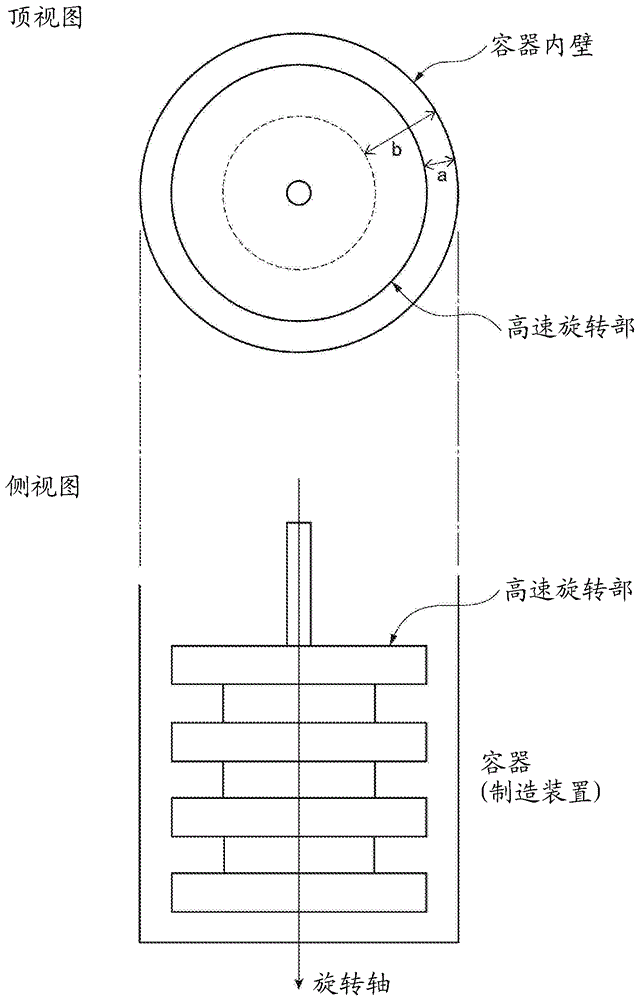

[0077] pass image 3 A urea-based grease manufacturing apparatus of the type shown is used to manufacture grease. A specific method for producing the grease is as follows.

[0078] PAO base oil [poly-α-olefin (40°C kinematic viscosity is 63mm at 40°C) heated to 70°C 2 / s, the kinematic viscosity at 100°C is 9.8mm 2 / s), containing 3.4% by mass of cyclohexylamine and 13.7% by mass of octadecylamine] and the same heated to 70°C PAO base oil [polyα-olefin (40°C kinematic viscosity is 63mm 2 / s, the kinematic viscosity at 100°C is 9.8mm 2 / s), containing 6.0% by mass of MDI] were continuously introduced into the manufacturing device at flow rates of 508mL / min and 890mL / min, respectively, and immediately applied to the mixed solution for 216,000s through the high-speed rotating part while the mixed solution passed through the gap. -1 the highest shear rate. In addition, the ratio (Max / Min) of the highest shear rate (Max) to the lowest shear rate (Min) during passage through th...

Embodiment 2

[0081] In Example 1, grease was produced in the same manner except that the flow rate of the amine solution was 178 mL / min and the flow rate of the MDI solution was 331 mL / min.

Embodiment 3

[0083] In Example 1, grease was produced in the same manner except that the flow rate of the amine solution was 253 mL / min and the flow rate of the MDI solution was 444 mL / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com