Winding machine for producing laps and method for winding slivers

A technology of winding machine and fiber strip, which is applied in the field of winding fiber strip, can solve the problems of uneven coiling and unusability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

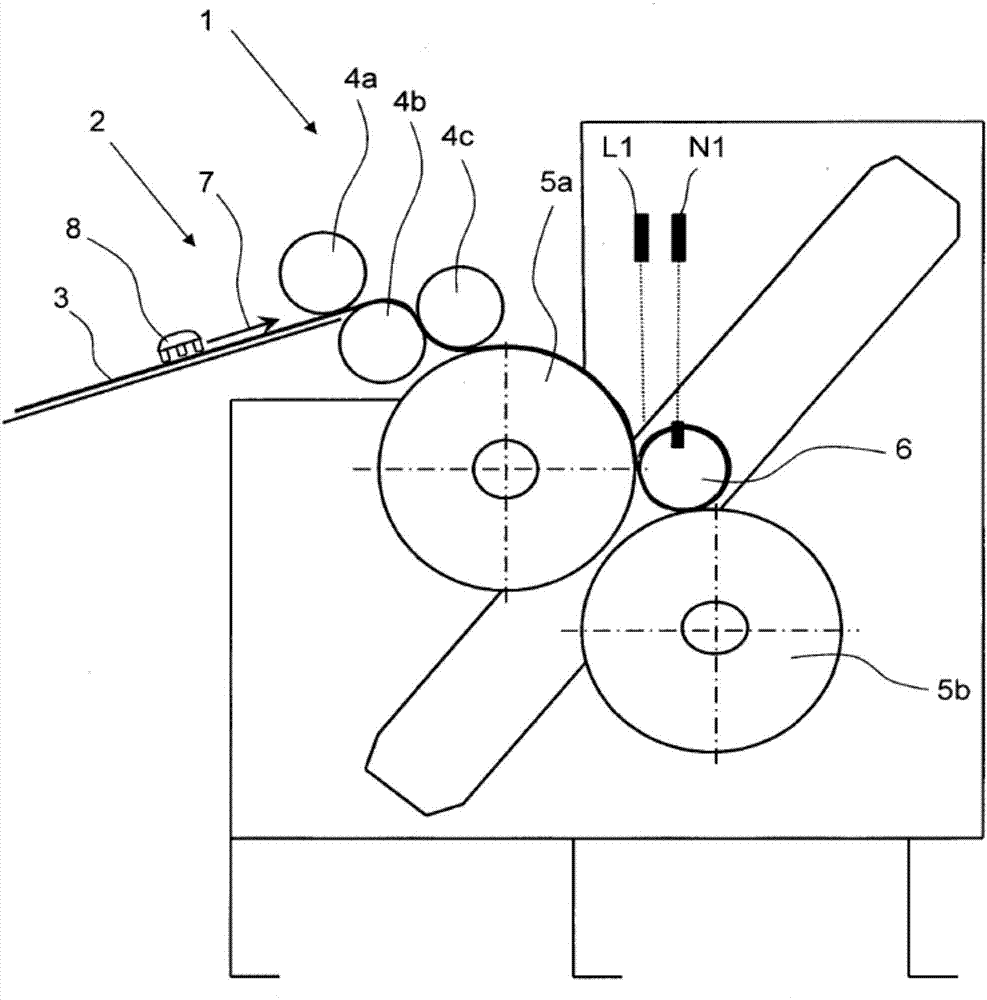

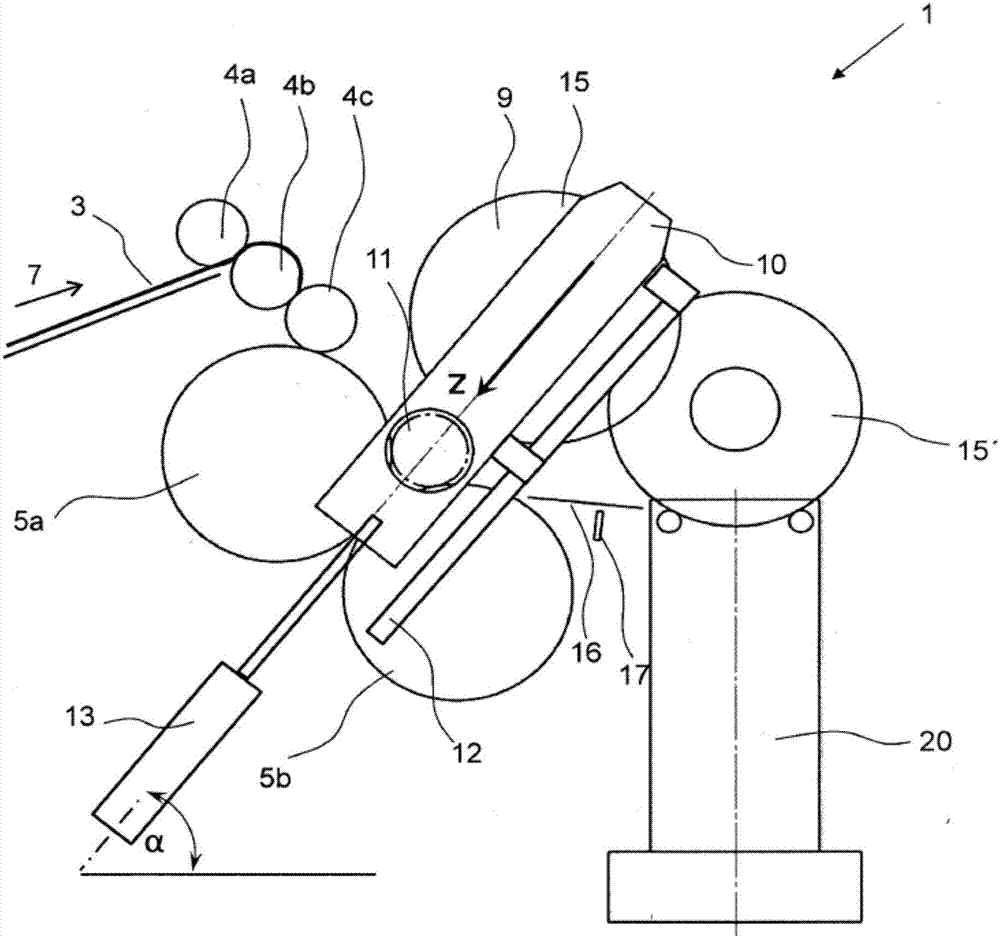

[0024] exist figure 1 shows how a winder 1 is used, for example, in the textile industry in combing preparations. A plurality of fiber strands 3 , which may be made of natural or synthetic fibers, are conveyed through the cans of the winder 1 and stretched in a drafting device (not shown). The fiber sliver 3 is further guided through the feed area 2 to a plurality of press rollers 4a-4c, which guide the fiber sliver 3 between the two winding rollers 5a, 5b and the winding bobbin 6 for making the lap. in the pull-in area between them. A booster 8 can be arranged in or above the feed region 2 , which homogenizes the fiber sliver 3 . The table calender arranged in the feed area 2 , the drafting device arranged upstream of the table calender and the creel arranged upstream of the winder 1 are not shown. Alternatively, the laps can also be produced in the continuous endless conveyor belt or between one or two pressure rollers and the endless conveyor belt. Furthermore, a sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com