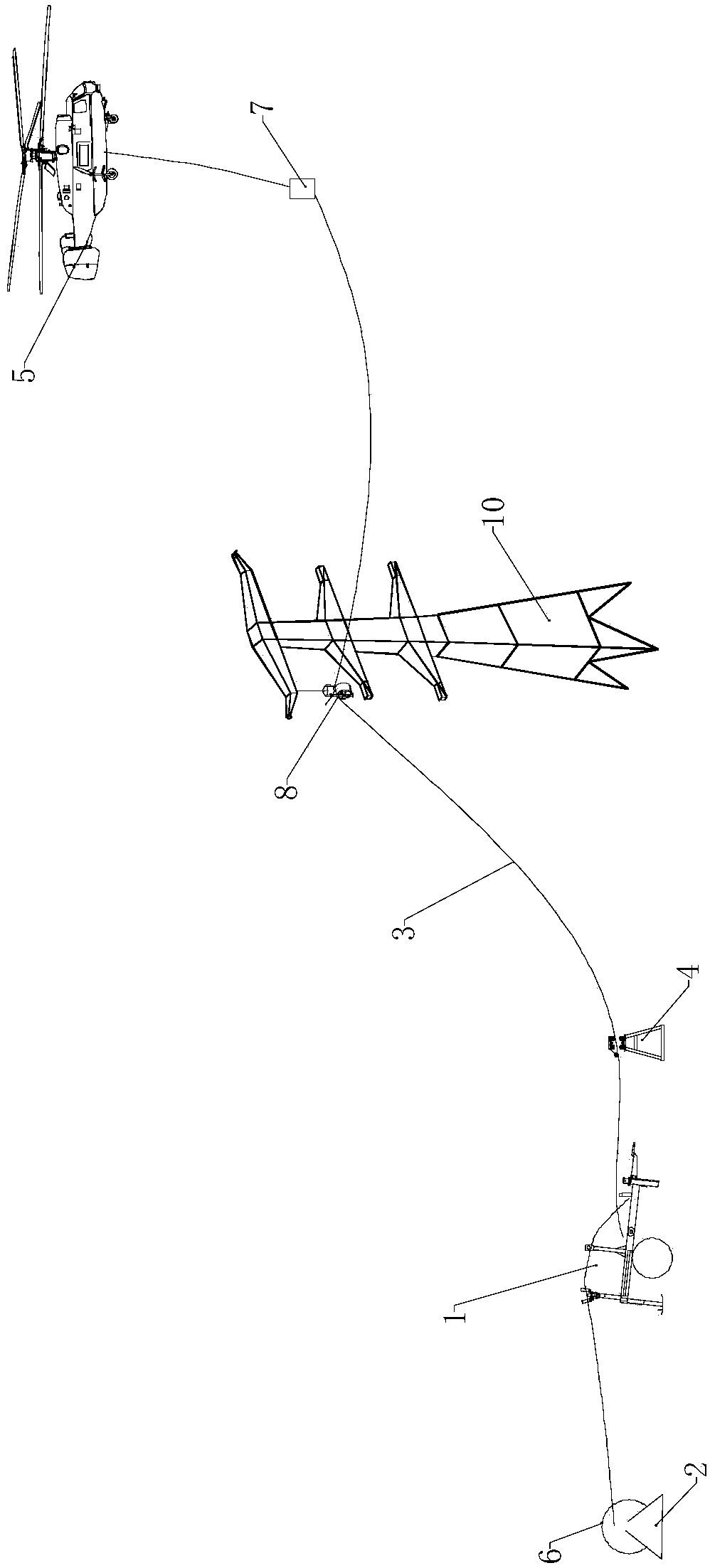

A method for a helicopter to deploy a guide rope

A guide rope and helicopter technology, which is applied in the direction of thin material handling, overhead line/cable equipment, and conveying filamentous materials, etc., can solve the problems of multiple winding layers and long time consumption, so as to reduce work, improve safety and The effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

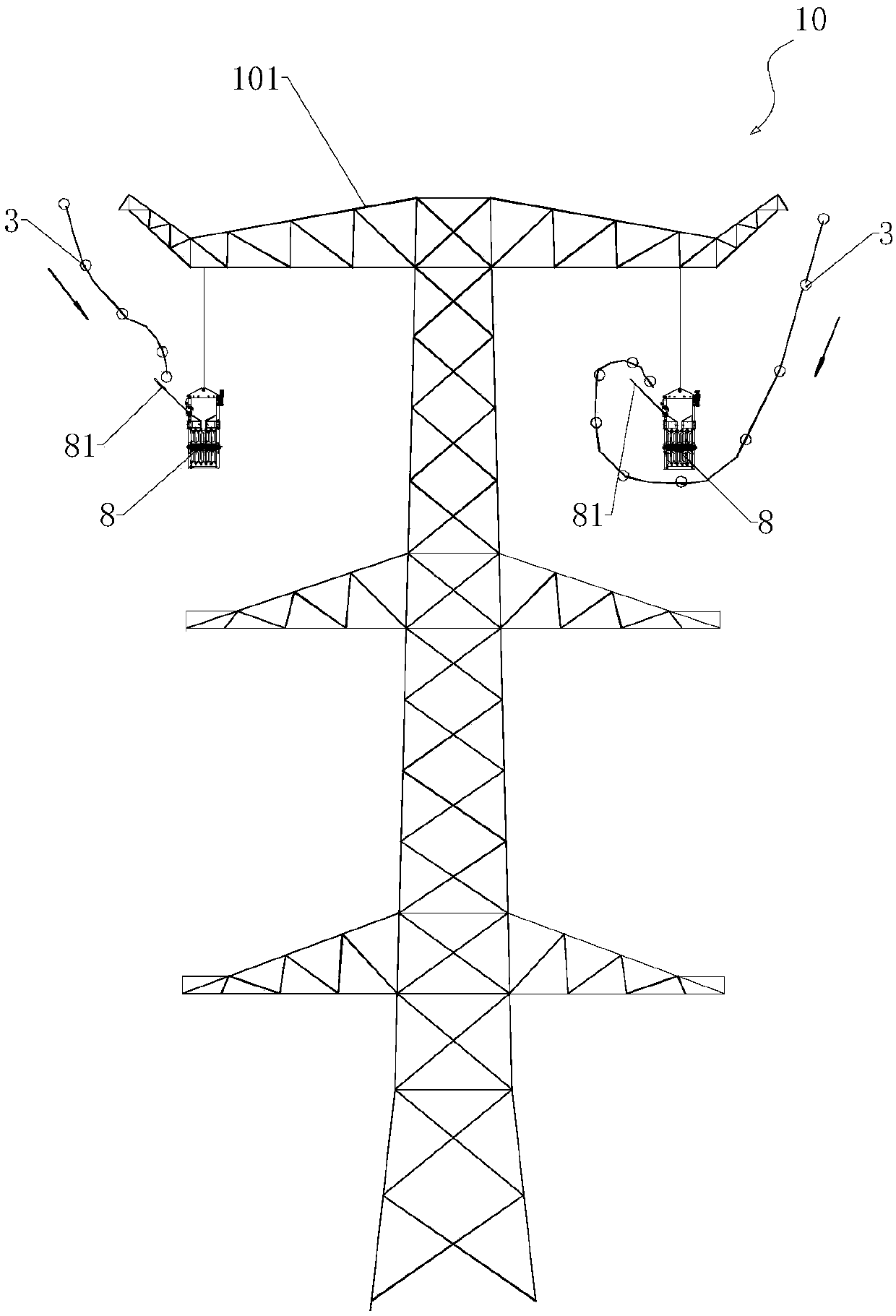

[0054] Such as figure 2 As shown, corresponding to the iron tower 10 is provided with a side cross arm 101, the two ends of the side cross arm 101 hang the situation of the guide rod type tackle 8 respectively; the helicopter 5 flies over the iron tower 10, Control the flight trajectory of the helicopter 5 so that the guide rope 3 slowly approaches the guide rod block 8 until it can pass through the guide rod of the guide rod block 8 and automatically fall into the guide rod block 8, The helicopter 5 then flies forward at normal speed.

[0055] If the guide rod 81 of the guide rod type block 8 stretches out to the outside of the iron tower 10, as figure 2 In the case on the left side of the figure, the movement track of the cross section of the guide rope 3 is used to represent the movement track of the guide rope 3 under the traction of the helicopter 5. The guide rope 3 descends from the outside of the iron tower 10 and approaches Described guide rod 81 directly slides a...

Embodiment 2

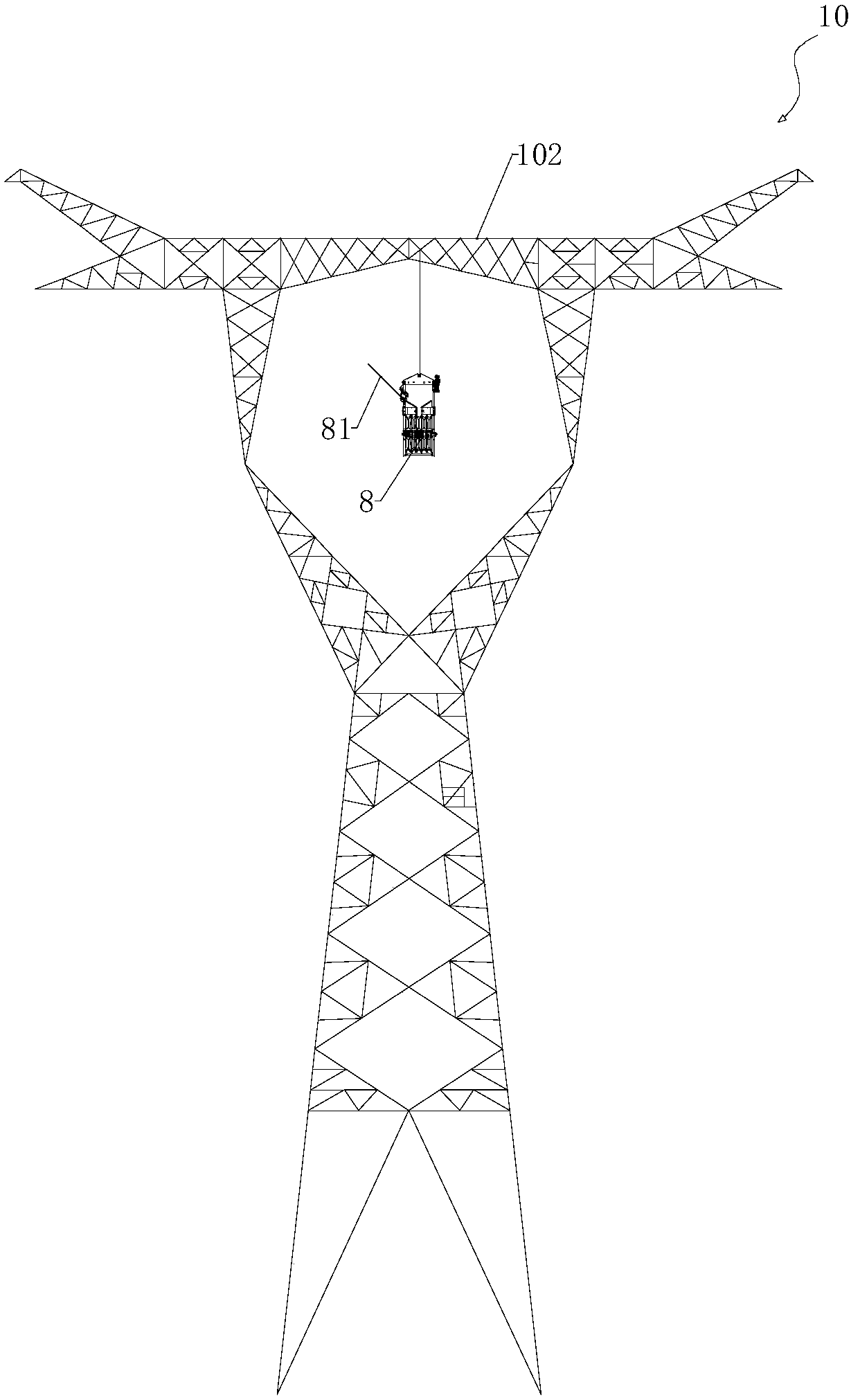

[0057] Such as image 3 As shown, corresponding to the iron tower 10 is provided with a middle phase cross arm 102, the middle part of the middle phase cross arm 102 hangs the situation of the guide rod type block 8; the guide rod type block 8 is suspended on the single circuit wine glass tower In the middle window, the helicopter 5 flies to the sky above the iron tower 10, controls the flight path of the helicopter 5, and cooperates with the operator on the iron tower 10 to operate the intermediate phase device 9 to make the intermediate phase device 9 Pass the guide rope 3 under the middle phase cross-arm 102 (that is, inside the window), and make the guide rope 3 automatically fall into the In the guide rod type block 8. Its specific implementation steps can be understood in conjunction with the part about the use method of the intermediate phaser 9 in the patent document CN 204407794 U. Here, compare Figures 4A-4IGive an example.

[0058] Figure 4A Shown as step 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com