An electric vehicle battery thermal management system

A battery thermal management, electric vehicle technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as poor heat dissipation, and achieve the effect of improving heat exchange rate, small resistance loss, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

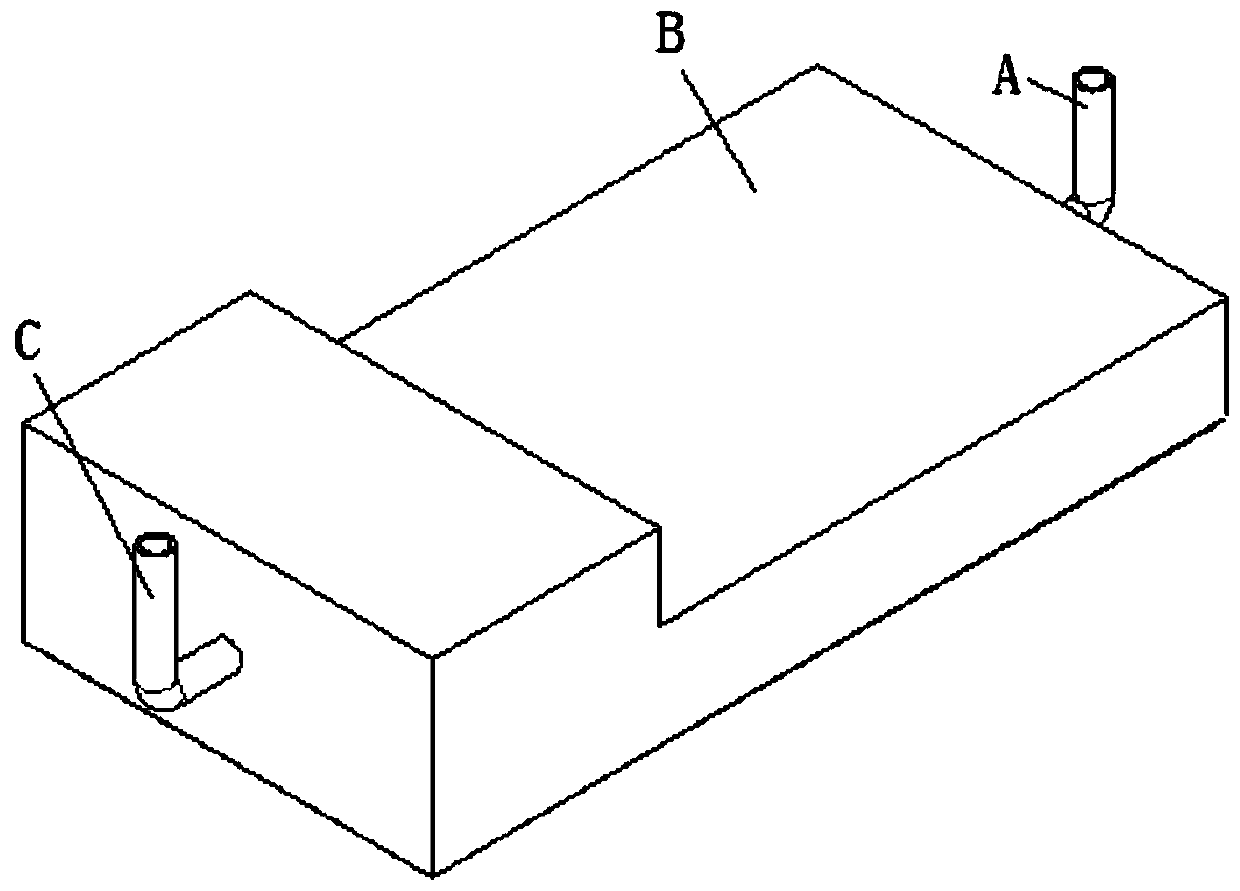

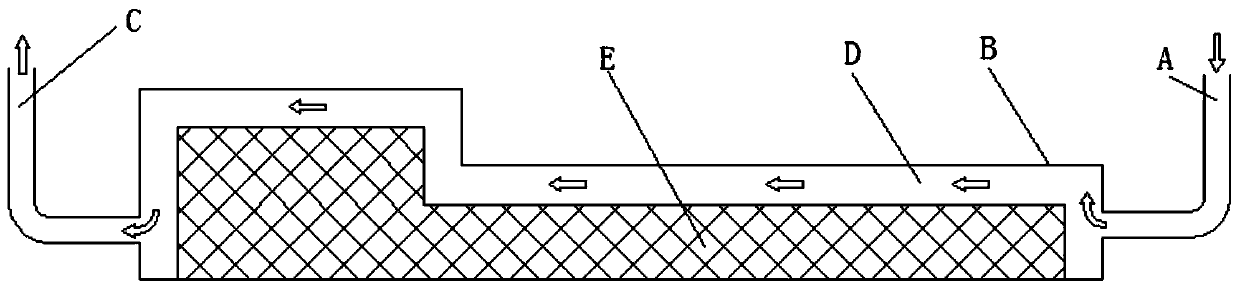

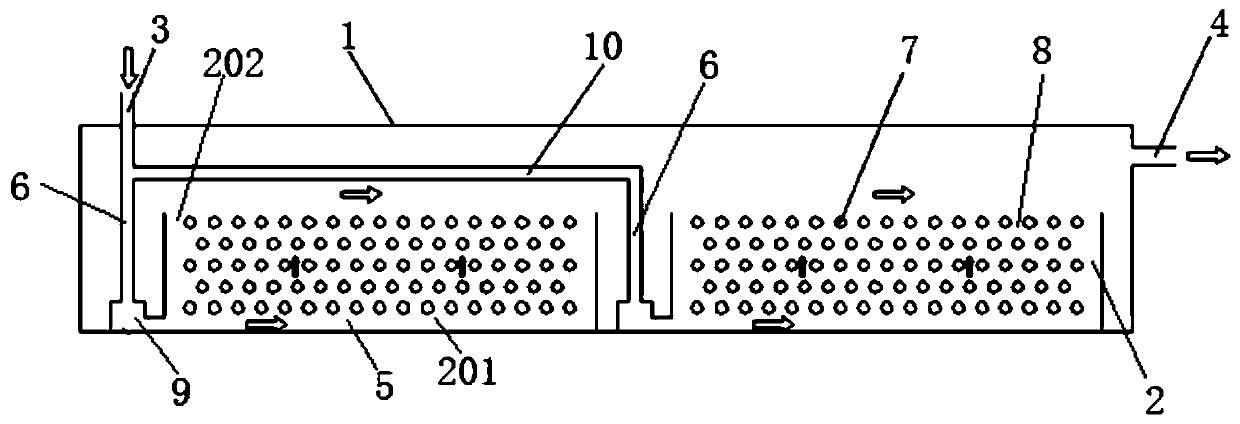

[0044] An embodiment of the present invention provides an electric vehicle battery thermal management system, such as image 3 As shown, the electric vehicle battery thermal management system includes: a battery pack case 1; a plurality of battery modules 2 connected at the bottom of the battery pack case 1; 3, and the battery pack air outlet 4 provided at the other end of the upper part of the battery pack case 1;

[0045] Wherein, the bottom 201 of the battery module is provided with a cavity 5;

[0046] There is a heat dissipation air duct 6 inside the battery pack housing 1, and the upper end of the heat dissipation air duct 6 is connected to the air inlet 3 of the battery pack, and the lower end of the heat dissipation air duct 6 communicates with the cavity 5;

[0047] There are gaps 8 between the cells 7 inside the battery module 2 .

[0048] When the electric car is discharged, the battery cell 7 continuously generates heat, and the battery temperature continues to r...

Embodiment 2

[0055] An embodiment of the present invention provides an electric vehicle battery thermal management system, such as Figure 4 As shown, the electric vehicle battery thermal management system includes: a battery pack housing 1; a plurality of battery modules 2 connected to the top of the battery pack housing 1; a battery pack air inlet provided at one end of the lower part of the battery pack housing 1 3, and the battery pack air outlet 4 provided at the other end of the lower part of the battery pack case 1;

[0056] Wherein, the bottom 201 of the battery module is provided with a cavity 5;

[0057] There is a heat dissipation air duct 6 inside the battery pack housing 1, and the lower end of the heat dissipation air duct 6 is connected to the air inlet 3 of the battery pack, and the upper end of the heat dissipation air duct 6 communicates with the cavity 5;

[0058] There are gaps 8 between the cells 7 inside the battery module 2 .

[0059] When the electric car is disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com