Hot-pressing formation control method for lithium-ion batteries

A technology of lithium ion battery and control method, which is applied in the field of hot and cold pressing of lithium ion battery to achieve the effect of flexible detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

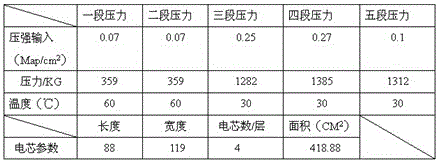

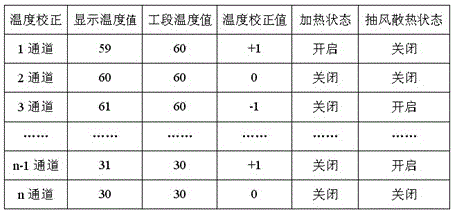

[0020] A kind of lithium-ion battery thermocompression forming control method described in the present invention, refer to Figure 1-2 , including the following steps:

[0021] A. Store multi-section operation control parameters, each operation control parameter includes cell size, section atmospheric pressure value and section temperature value;

[0022] B. Set up the forming fixture, place the forming fixture in the forming working chamber, and run the forming fixture step-by-step downward along the forming working chamber, and run for one stage step by step, triggering the operation control parameters stored in the corresponding stage;

[0023] C. Set the parameter device corresponding to the operation control parameters, the parameter device is set in the chemical working chamber, and includes a pressure device and a heating device, the pressure device pressurizes the battery cell, adjusts the atmospheric pressure value of each section, and the heating device Heating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com