Photovoltaic module and photovoltaic power generation system

A photovoltaic module and light-receiving surface technology, applied in the field of solar cells, can solve the problems of insufficient bonding force between a single-layer anti-reflection film and a substrate, low anti-reflection performance of the anti-reflection film, and single control means, etc., to reduce internal stress. , Good anti-reflection effect, and the effect of increasing power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

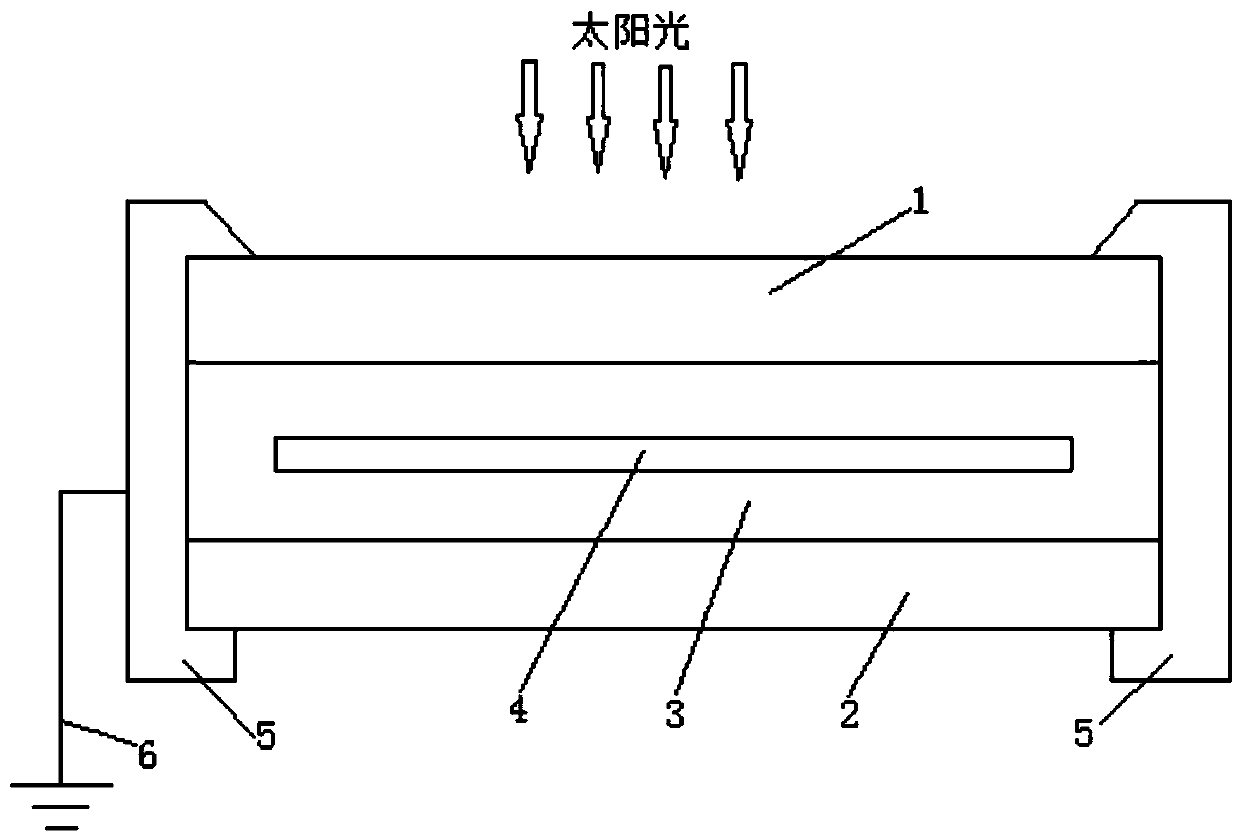

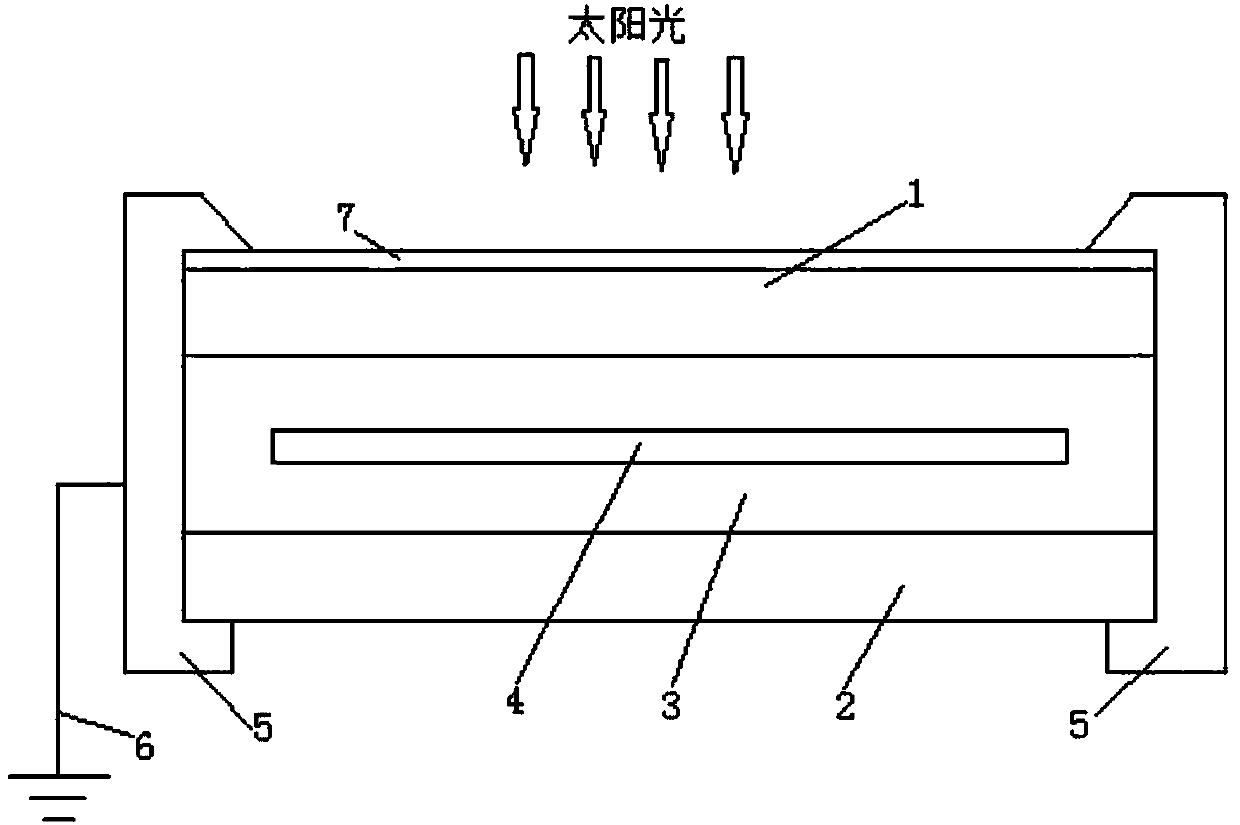

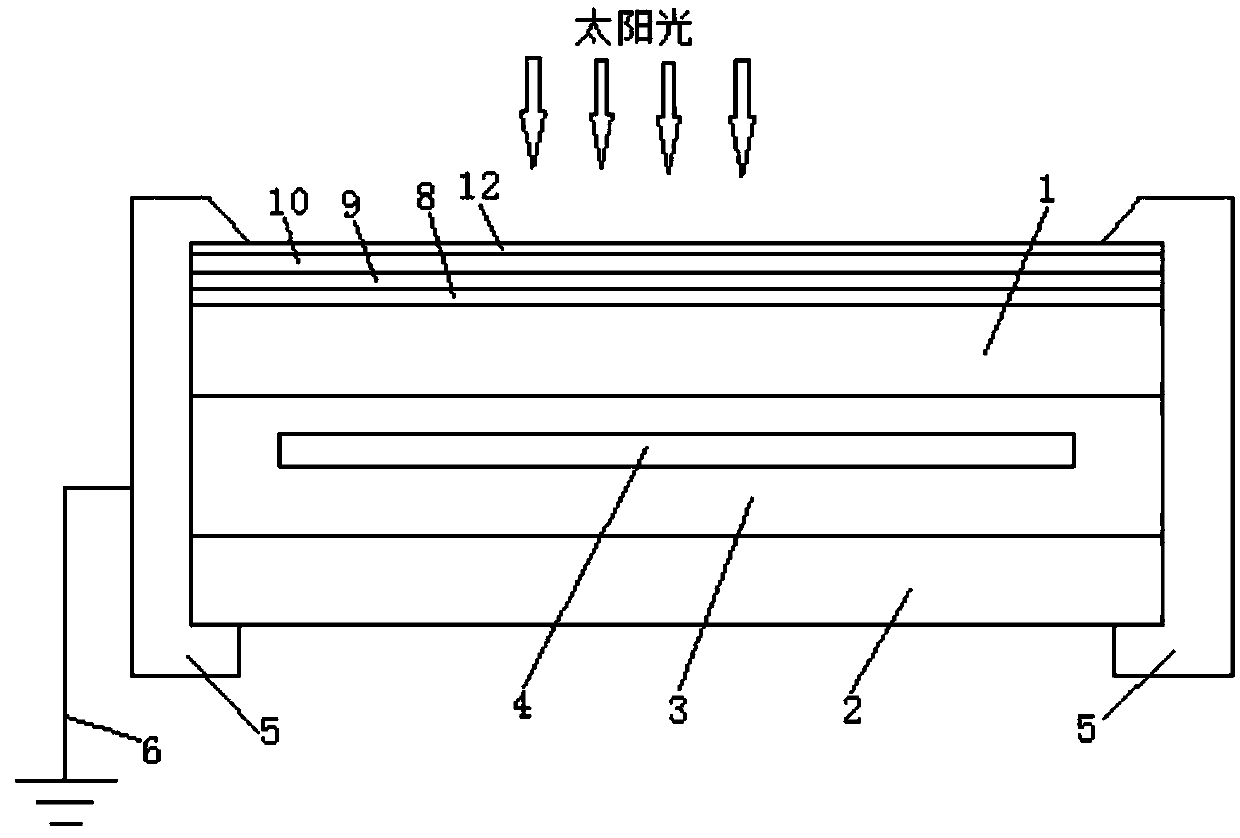

Embodiment 1

[0050] On the surface of a glass substrate with a thickness of 3mm, magnetron sputtering deposits a 20nm silicon oxide film layer as the first barrier layer 8; then, a 10nm Nb-doped titanium dioxide film is deposited on the silicon oxide film layer by magnetron sputtering layer as the conductive film layer 9; then on the Nb-doped titanium dioxide film layer, magnetron sputtering is used to deposit a 110nm silicon oxide film layer as the silicon-containing hydrophilic film layer 10; then on the silicon-containing hydrophilic film layer 10, CVD The titanium dioxide-based film layer 12 of 5nm is deposited by the method; then the glass deposited with the above film layer is subjected to tempering heat treatment, and the glass after the tempering heat treatment is used as the cover glass 1 of the photovoltaic module, and the film layer on the surface of the tempered glass faces the side of the photovoltaic module The light-receiving surface and the metal frame 5 of the photovoltaic ...

Embodiment 2

[0052] On the surface of a glass substrate with a thickness of 4mm, magnetron sputtering deposits a 25nm silicon oxynitride film layer as the first barrier layer 8; then adopts magnetron sputtering to deposit 15nm Ta-doped The titanium dioxide film layer is used as the conductive film layer 9; then on the Ta-doped titanium dioxide film layer, the silicon oxide film layer of 110nm is deposited by magnetron sputtering as the silicon-containing hydrophilic film layer 10; then on the silicon-containing hydrophilic film layer 10 A 3nm titanium dioxide-based film layer 12 is deposited by CVD; then the glass deposited with the above film layer is tempered and heat-treated, and the tempered glass is used as the cover glass 1 of the photovoltaic module, and the film layer on the surface of the tempered glass faces the photovoltaic The light-receiving surface of the module, and the metal frame 5 of the photovoltaic module is in contact with the Ta-doped titanium dioxide film layer 9, the...

Embodiment 3

[0054] On the surface of a glass substrate with a thickness of 4mm, magnetron sputtering deposits a 10nm zirconia film layer as the first barrier layer 8; then, a 5nm W-doped titanium dioxide film is deposited on the zirconia film layer by magnetron sputtering layer as the conductive film layer 9; then on the W-doped titanium dioxide film layer, magnetron sputtering is used to deposit a 105nm silicon oxide film layer as the silicon-containing hydrophilic film layer 10; then on the silicon-containing hydrophilic film layer 10, CVD The titanium dioxide-based film layer 12 of 7nm is deposited by the method; then the glass deposited with the above film layer is tempered and heat-treated, and the glass after the tempered heat treatment is used as the cover glass 1 of the photovoltaic module, and the film layer on the surface of the tempered glass faces the side of the photovoltaic module. The light-receiving surface, and at the same time, the metal frame 5 of the photovoltaic module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com