Product testing and supervision method and monitoring system thereof

A product testing and monitoring system technology, applied in data processing applications, resources, computing, etc., can solve problems that affect the performance of the target product tested, the quality of the test cannot be guaranteed, and affect the efficiency of product testing, so as to avoid task restart , Improve test efficiency and avoid waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

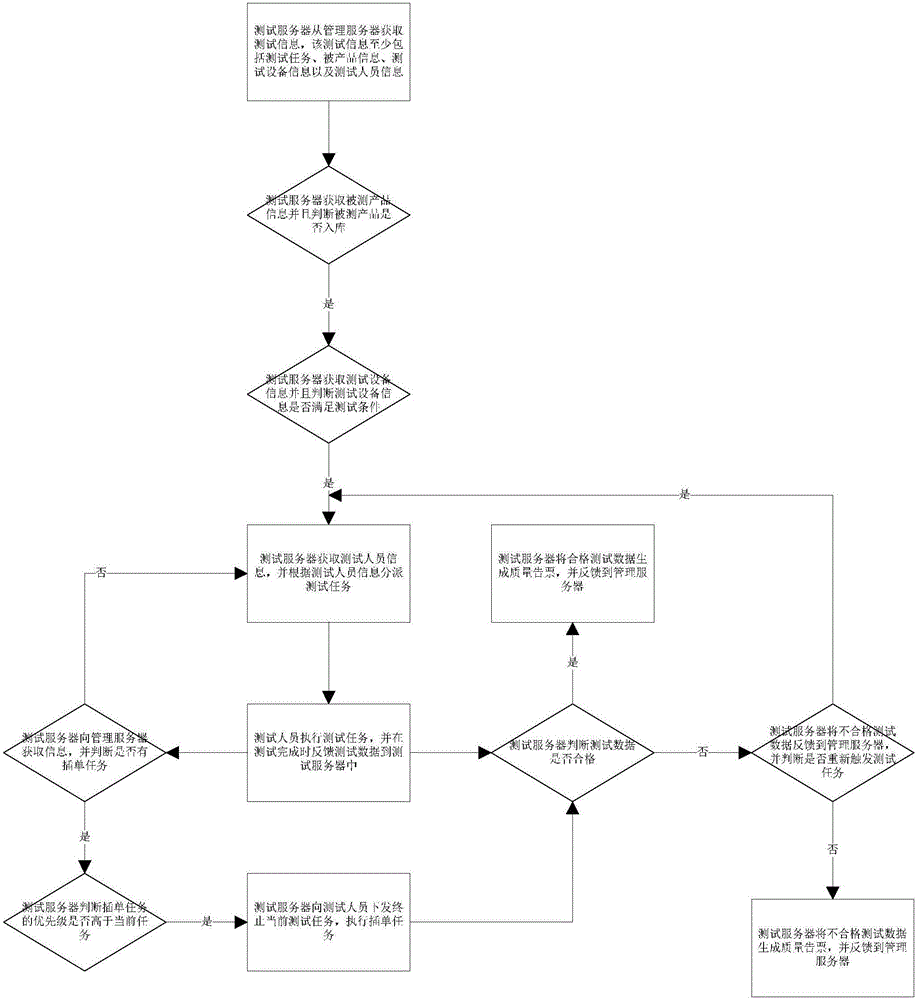

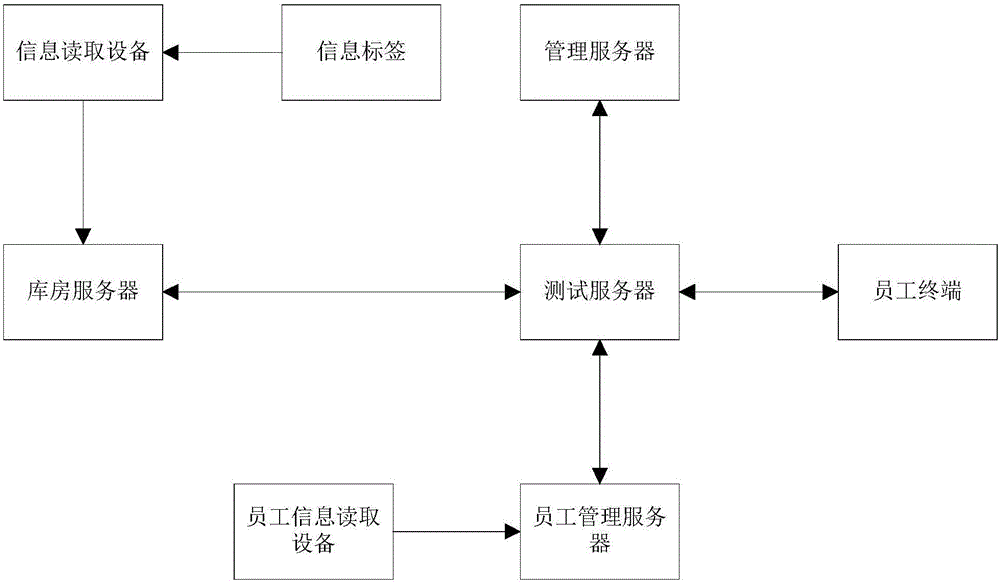

[0057] The following is attached figure 1 And figure 2 To further explain the present invention, the products in the present invention can be parts, such as intermediate products such as engines and brakes, or final products such as vehicles and lathes.

[0058] A product testing supervision method provided by the present invention includes the following steps:

[0059] S1. The test server obtains test information from the management server, the test information includes at least test tasks, tested product information, test equipment information, and tester information;

[0060] S2. The test server judges whether the current test information meets the test conditions, and if so, the test server assigns test tasks to the testers according to the tested product information, test equipment information, and tester information;

[0061] S3. The tester completes the test according to the test task, and uploads the feedback test data to the test server;

[0062] Wherein, the test tasks inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com