Method, device and system for detecting defects of liquid crystal screen

A technology of defect detection and LCD screen, which is applied in the field of detection to achieve the effect of improving accuracy, increasing contrast, and overcoming missed defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

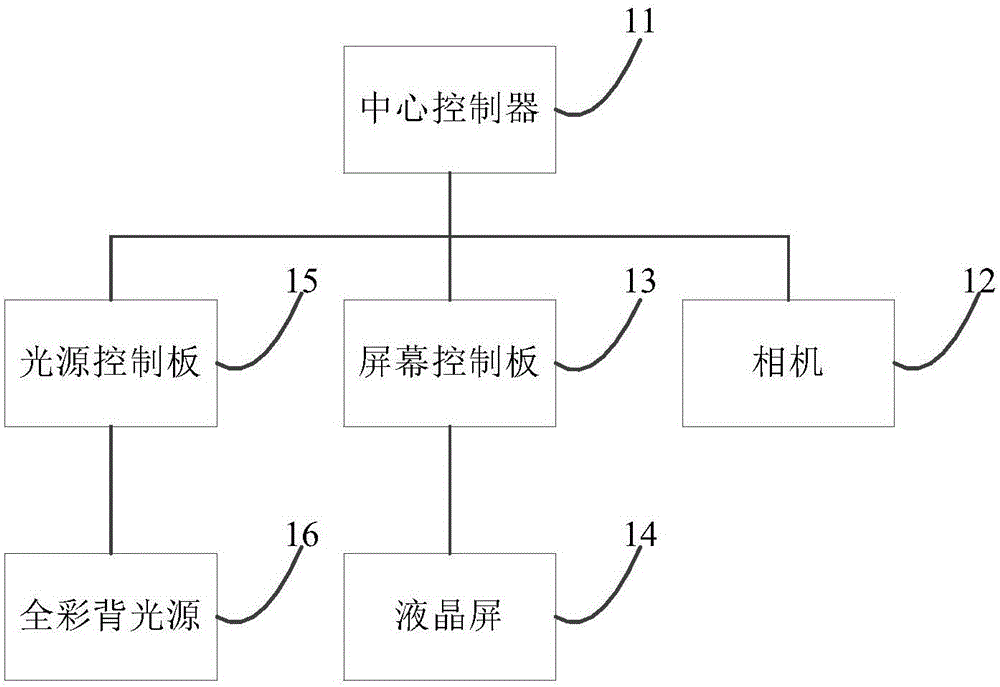

[0036] Embodiment 1 of the present invention provides a liquid crystal screen defect detection system, such as figure 1 As shown, the system includes: a central controller 11, a camera 12, a screen control board 13, a liquid crystal screen 14, a light source control board 15, and a full-color backlight 16;

[0037] In the liquid crystal screen defect detection system, in addition to the components included in the above system, it also includes auxiliary components such as brackets, conveyor belts, and power supply devices. Auxiliary components are indispensable and commonly used in liquid crystal screen detection, and in the embodiment of the present invention, the auxiliary components are not the key to solving the problem of missing detection during the detection process, so the detailed description of the auxiliary components will not be given here.

[0038] The central controller 11 is configured to send screen control signals.

[0039] The central controller 11 is the ma...

Embodiment 2

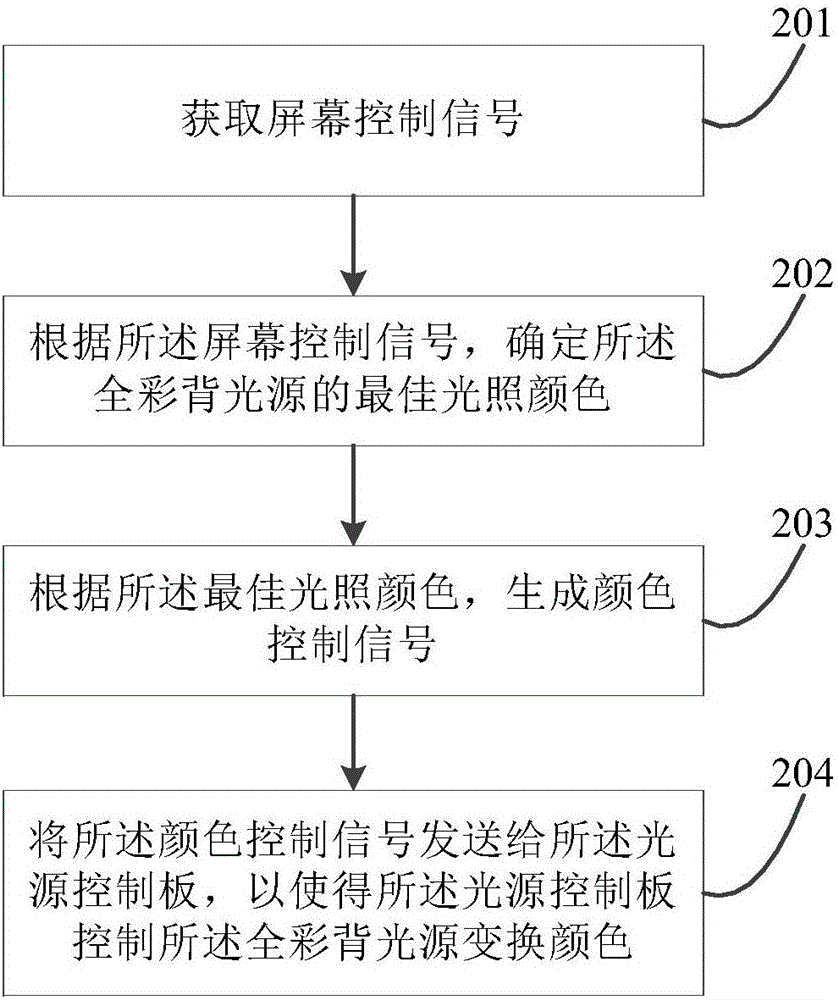

[0061] Embodiment 2 of the present invention provides a liquid crystal screen defect detection method, which is applied to a liquid crystal screen defect detection system. The system includes a central controller, a camera, a screen control board, a liquid crystal screen, a light source control board, and a full-color backlight, such as figure 2 As shown, the method includes:

[0062] 201. Acquire a screen control signal.

[0063] The screen control signal refers to the signal that controls the display on the LCD screen. Obtain the screen control signal sent by the control center, so as to determine the change of the LCD screen according to the screen control signal.

[0064] 202. Determine an optimal illumination color of the full-color backlight according to the screen control signal.

[0065] When detecting defects on the LCD screen, it was found that when the white backlight evenly irradiates the LCD screen, the LCD screen lights up with a monochrome background image, a...

Embodiment 3

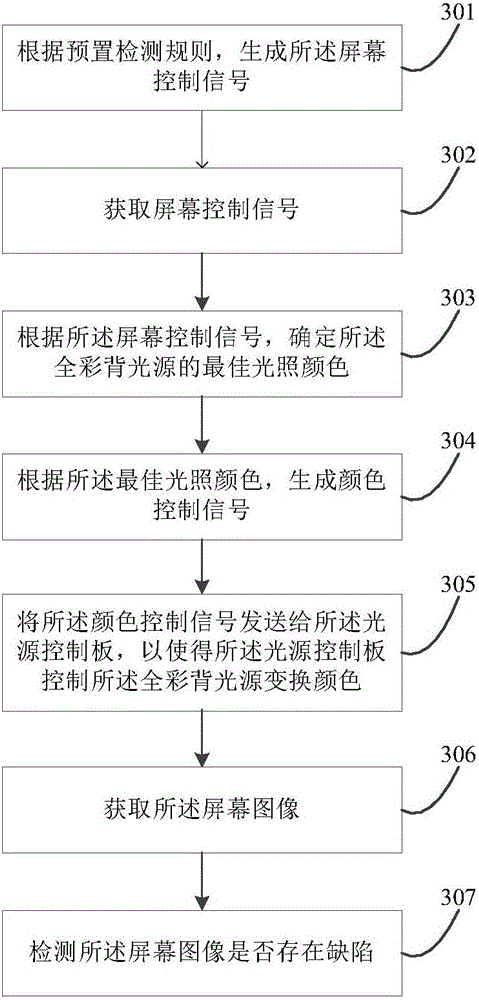

[0073] Embodiment 3 of the present invention provides another liquid crystal screen defect detection method, which is applied to a liquid crystal screen defect detection system. The system includes a central controller, a camera, a screen control board, a liquid crystal screen, a light source control board, and a full-color backlight. like image 3 As shown, the method includes:

[0074] 301. Generate the screen control signal according to a preset detection rule;

[0075] When detecting liquid crystal screen defects, it is necessary to detect the filtering conditions of the liquid crystal screen under different bandpass conditions, so before the detection starts, a screen control signal is generated. The screen control signal refers to a continuous control signal that controls the LCD screen multiple times during one LCD screen detection process. The preset detection rules can be arranged from high to low according to the defect probability of the LCD screen; they can also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com