Omnidirectional dynamic observation method for uniaxial compression crack propagation in coal and rock mass

A crack propagation and uniaxial compression technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems that a single camera is difficult to reflect the overall crack growth, analysis distortion, crack growth dependence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

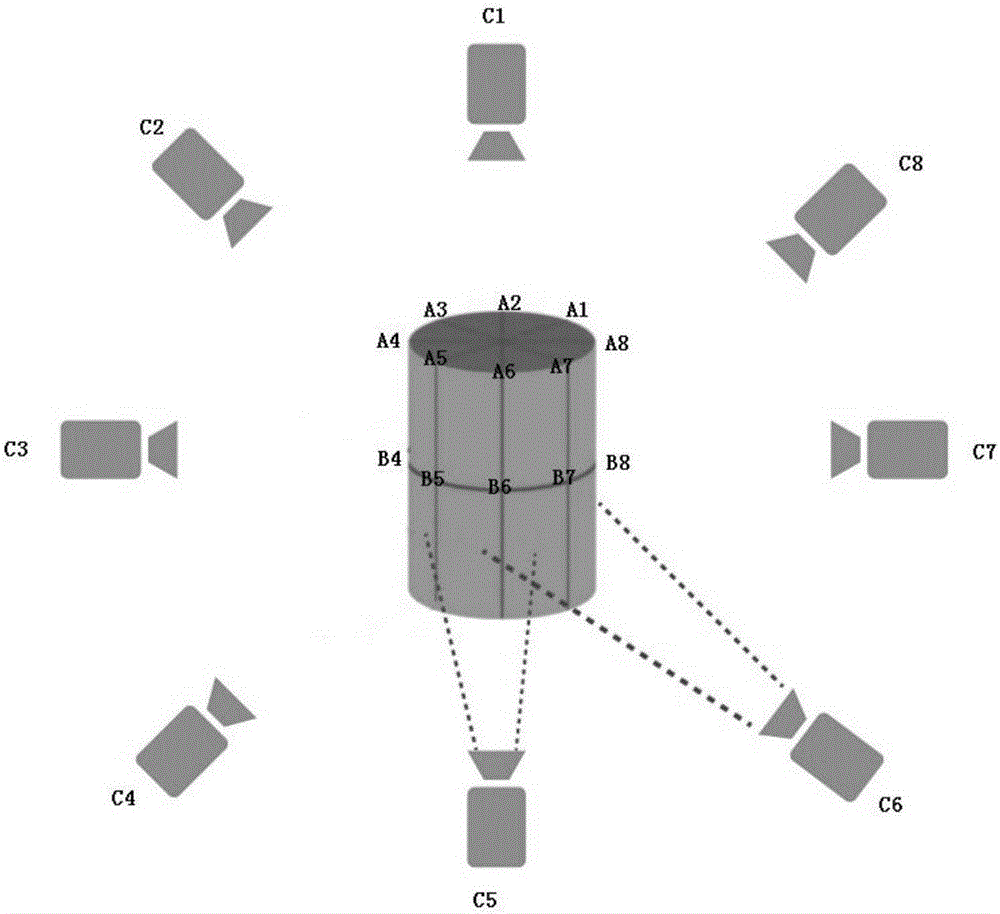

[0034] An all-round dynamic observation method for uniaxial compression crack propagation of coal and rock mass includes the following steps:

[0035] S101: Select the coal block in the coal mining face of the mine, and drill a standard compression test cylinder of φ50mm×100mm. The processing accuracy of the sample, the requirements and preparation of the compression instrument, and the requirements for the placement of the sample are all in accordance with the standards of the International Society of Rock Mechanics.

[0036] S102: Draw 8 vertical straight lines on the coal sample so that the included angle between them is 45°, and the labels are A1, A2, A3, ..., A8. Use a ruler to measure the midpoints of the eight vertical straight lines, and use the Tajima hand-rolled ink fountain ink line PS-RAKT to connect the eight points in turn into a closed horizontal curve.

[0037] S103: Taking the specific position of the cylindrical coal body on the workbench as the center, place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com