Passenger car ABS brake test bench device

A brake test, passenger car technology, applied in the direction of measuring device, vehicle test, machine/structural component test, etc., can solve the problem that the contact situation of passenger car cannot be simulated more realistically, and achieve the effect of less capital consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

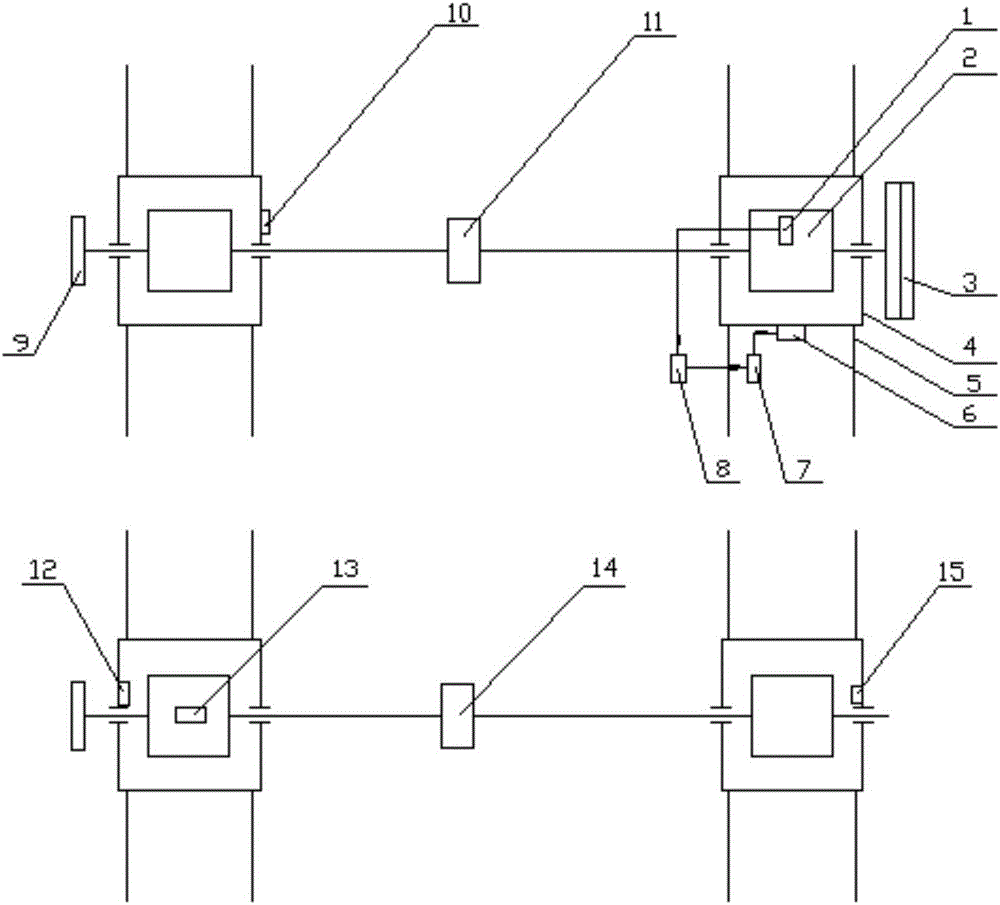

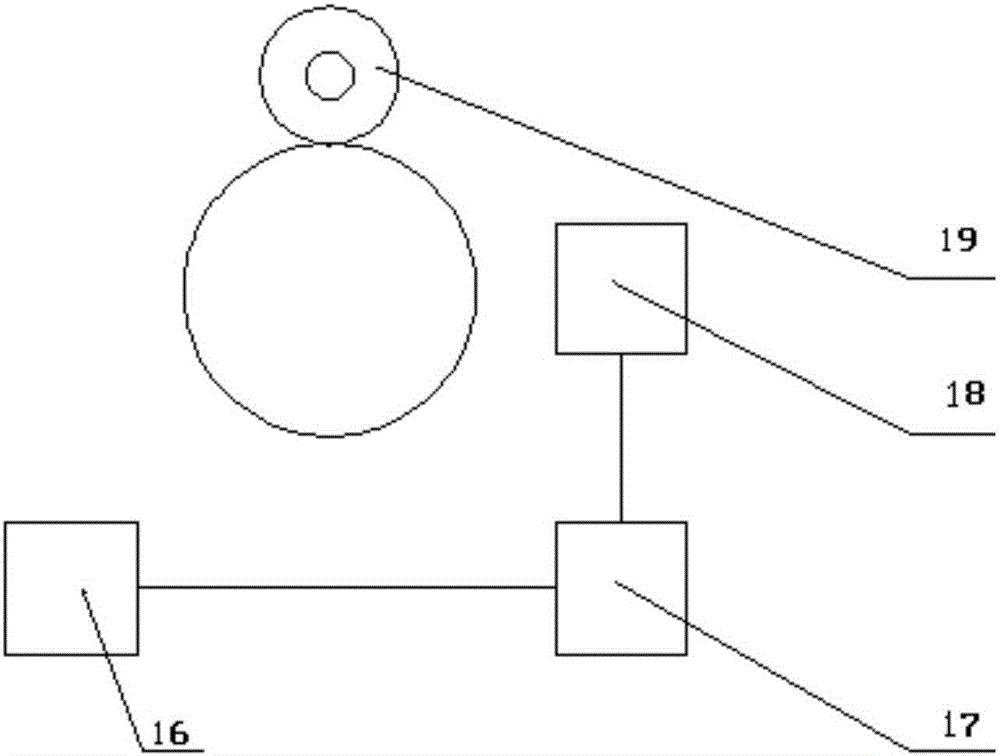

[0011] 1. Humidity sensor, 2. Roller, 3. Flywheel, 4. Roller rack, 5. Rack slide rail, 6. Automatic sprinkler, 7. Flow control valve, 8. Central processing unit, 9. Sprocket, 10. Wheel speed sensor, 11. A torque measuring instrument, 12. Drum speed sensor, 13. Wheel load sensor, 14. B torque measuring instrument, 15. Wheel position sensor, 16. Gravel collecting device, 17. Transmission device, 18, feed mechanism, 19, wheel.

[0012] Below in conjunction with accompanying drawing, the present invention will be further described

[0013] Such as figure 1 as well as figure 2 Shown: a kind of passenger car ABS braking test bench of the present invention comprises: humidity sensor 1, drum 2, flywheel 3, drum frame 4, rack type slide rail 5, automatic sprinkler 6, flow control valve 7 , central processor 8, sprocket 9, wheel speed sensor 10, wheel speed sensor, A torque measuring instrument 11, drum speed sensor 12, wheel load sensor 13, B torque measuring instrument 14, wheel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com