A high-speed automatic online detection device for LED lamp integrated chip junction temperature

A technology of LED lamps and integrated chips, which is applied in the field of high-speed automatic detection devices for junction temperature of LED integrated chips, and can solve problems such as inability to obtain junction temperature data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

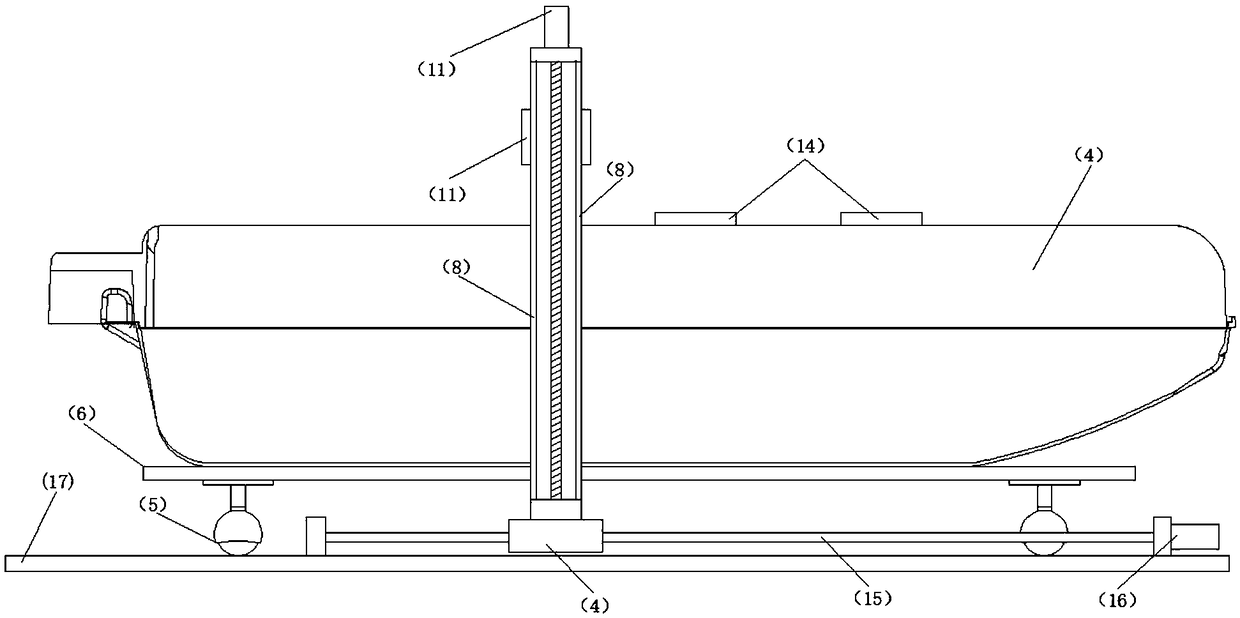

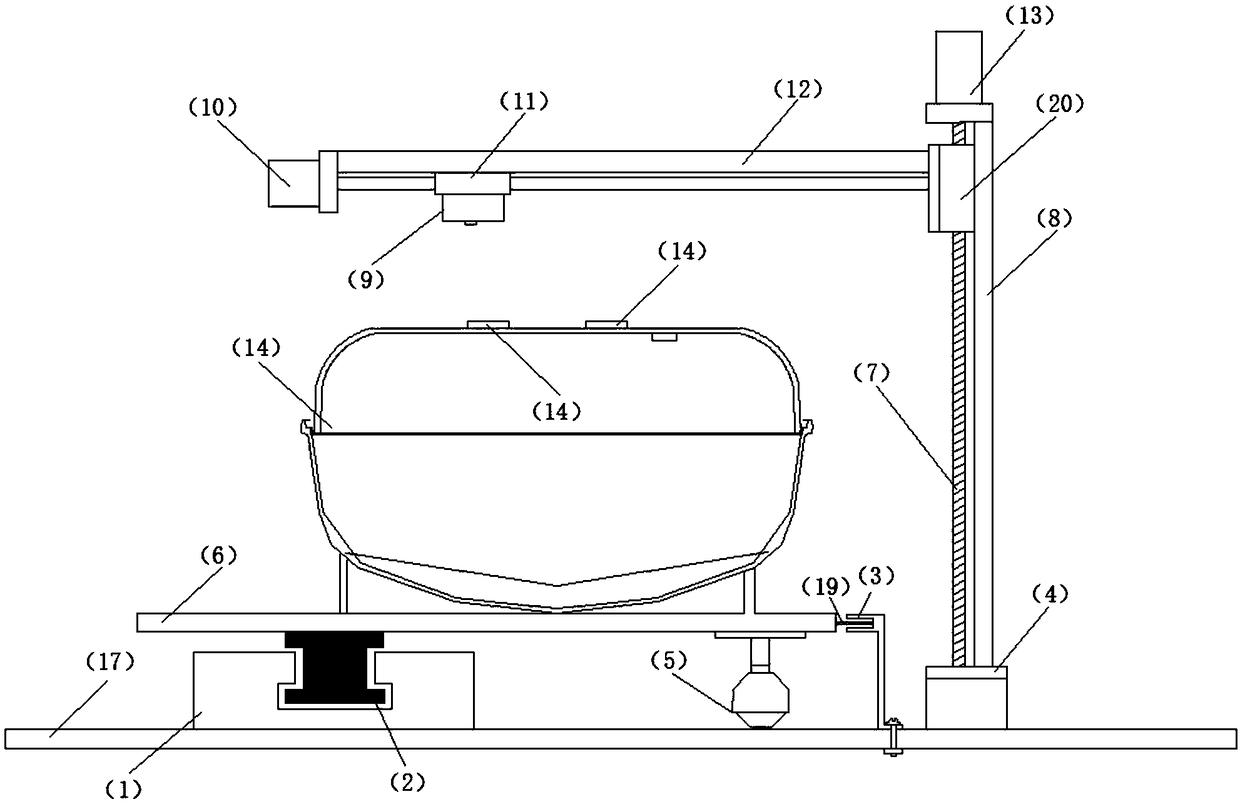

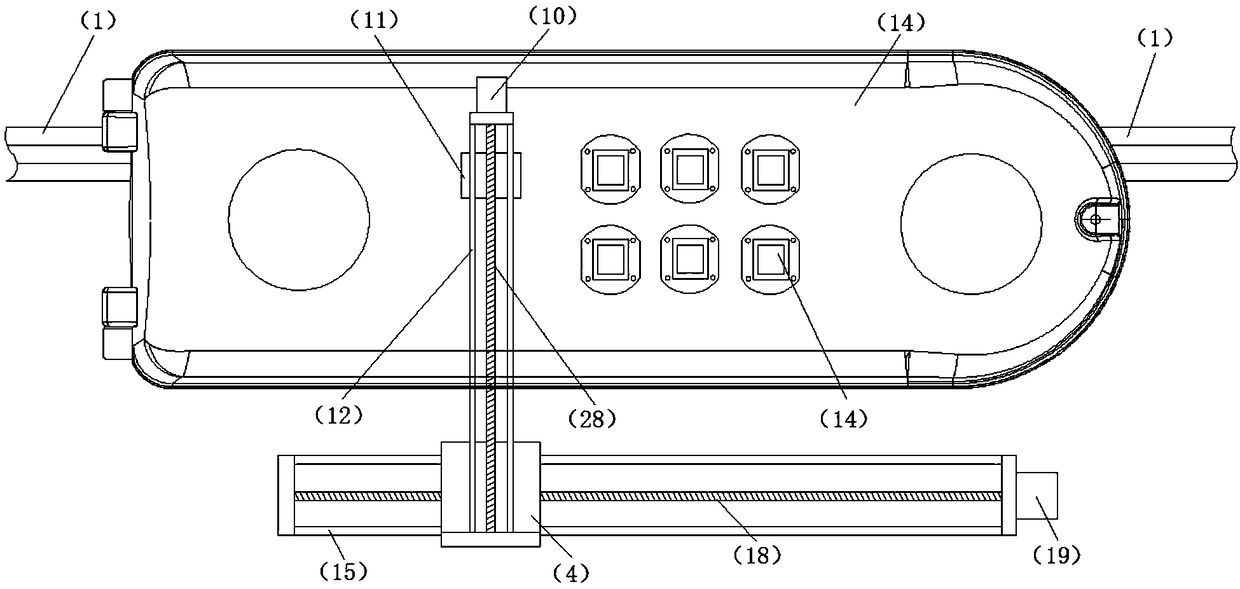

[0027] A high-power LED integrated chip junction temperature high-speed automatic detection device, comprising a polyvinyl chloride sliding guide 1, a chain 2, a production line chain rail motor controller 25, a production line chain rail motor driver 26, a production line chain rail motor 27, and an unpowered corner chain The slide rail automatic production line composed of the wheel 31, the power corner sprocket 30, and the production line assembly car 6. The computer and the production line chain rail motor controller 25 program jointly complete the control of the production line sequence and step sequence. The invention adopts the running mode of the sprocket and the sliding rail, and the assembly vehicle of the production line is fixed on the chain pendant, and is driven by the chain to travel. Two swivel wheels are installed under the assembly car on the production line to overcome the speed difference when cornering. The sprocket method is adopted at the 90° corner of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com