Integrated bandpass filter, manufacturing method thereof and spectrometer

A band-pass filter and manufacturing method technology, applied in the field of optics, can solve the problems of bulky size, inability to meet the application requirements of miniaturization and speed, slow speed, etc., and achieve the effect of easy preparation, low cost and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following description, numerous specific details are set forth in order to provide a thorough understanding of the invention. The present invention may be practiced without some or all of these specific details. In other instances, well known process operations have not been described in detail in order not to unnecessarily obscure the present invention. While the invention will be described in conjunction with specific embodiments, it will be understood that they are not intended to limit the invention to those embodiments.

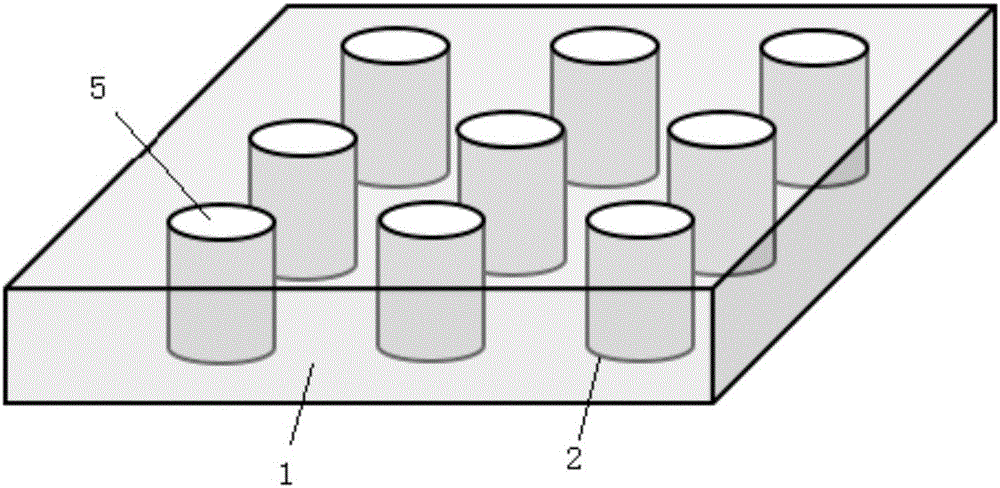

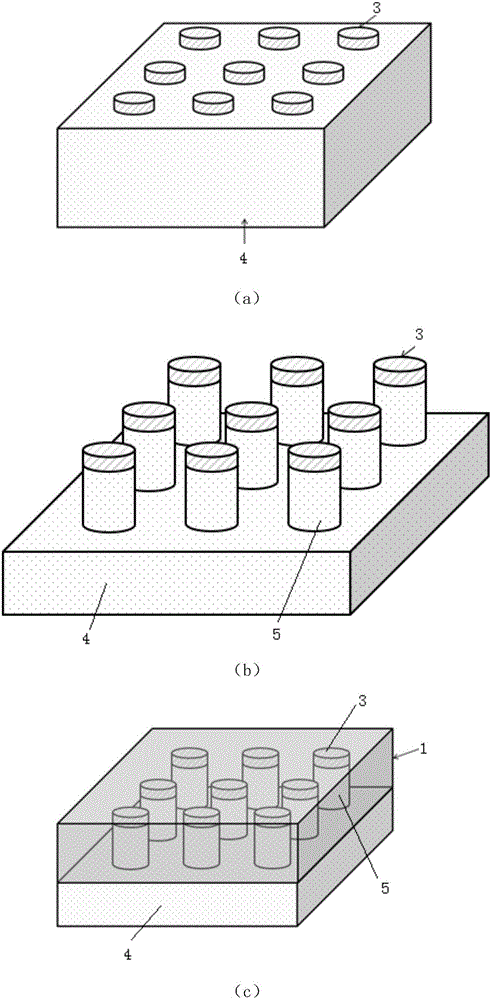

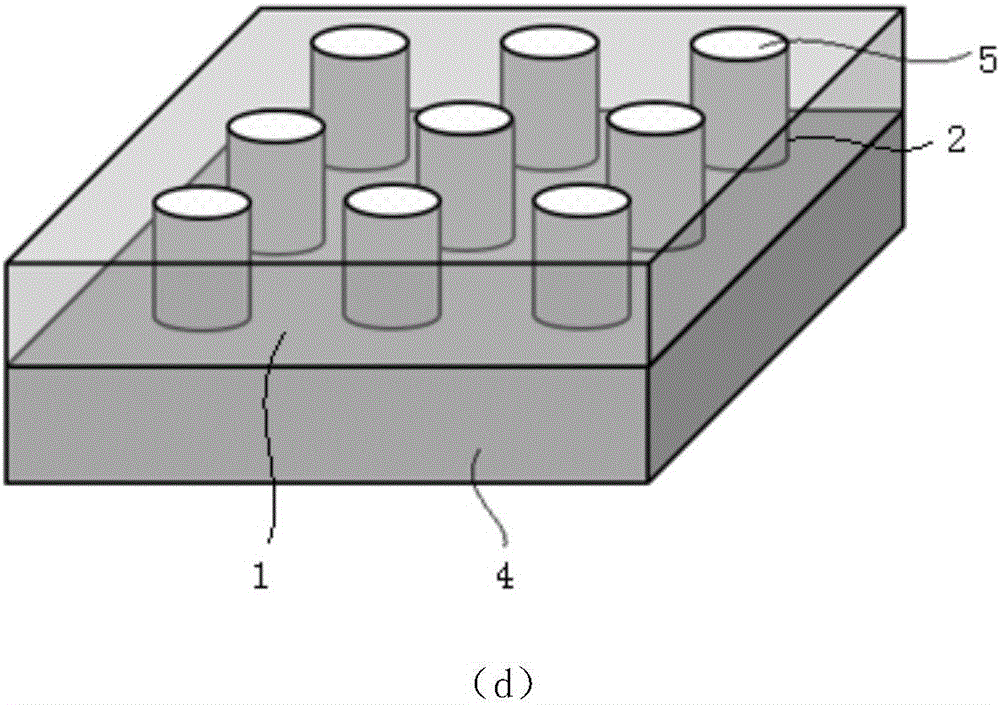

[0028] figure 1 It is a structural schematic diagram of the integrated bandpass filter of the present invention. like figure 1 As shown, the integrated bandpass filter of the present invention includes a metal layer or a layer 1 mainly of metal, in which a through micron or nanohole array is formed, i.e. metal micron or nanohole Array 2, the characteristic wavelength λ of the light passing through the metal micro or nano hole (metal hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com