Turntable error detection method based on multi-station etalon laser tracking system

A technology of laser tracking and error detection, applied in measurement devices, optical devices, instruments, etc., can solve problems such as cable disturbance errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

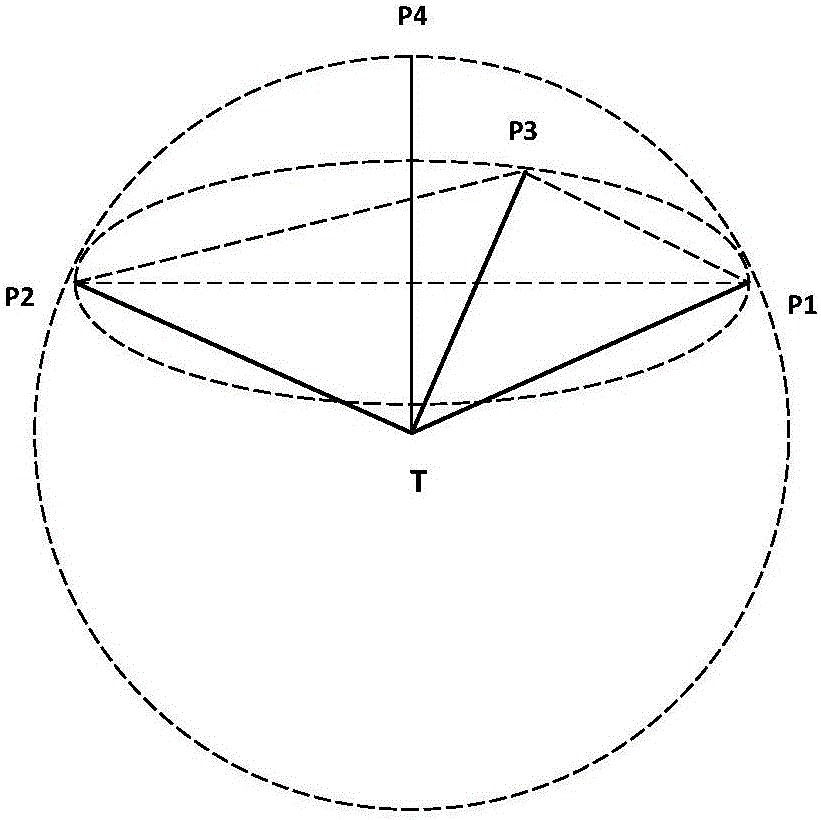

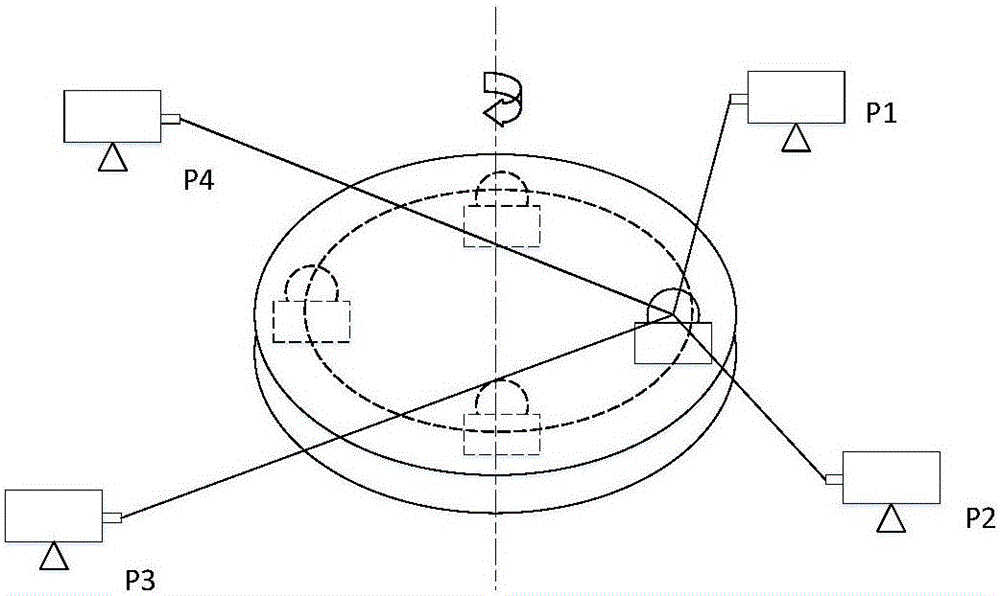

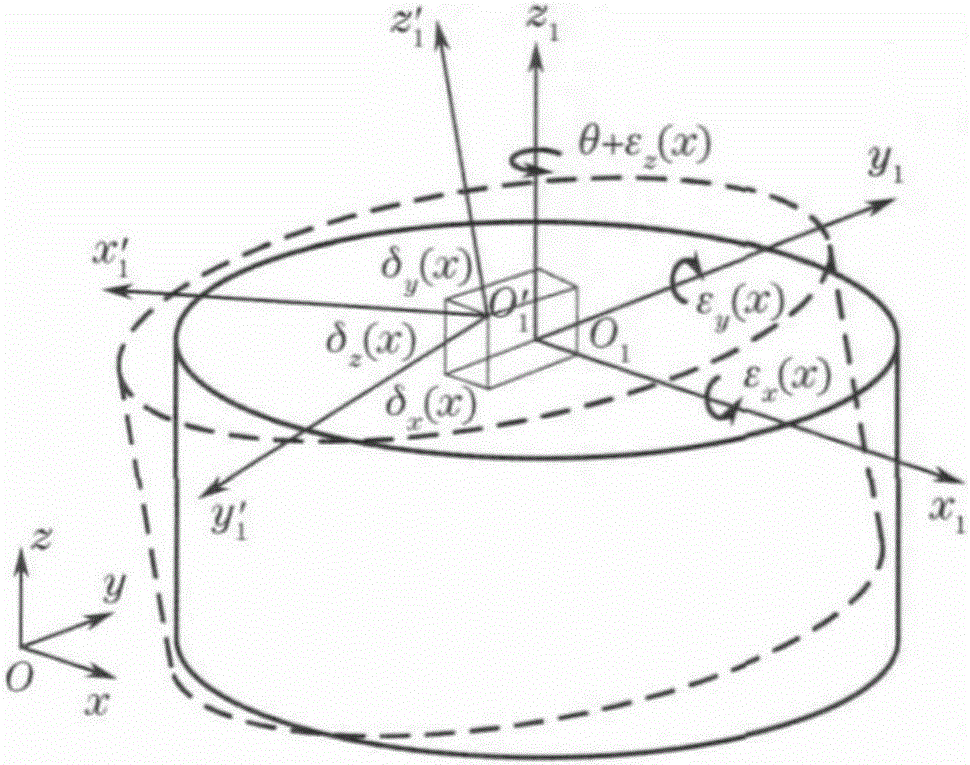

[0070] The invention is based on a multi-station etalon laser tracker's numerical control turntable rotation error detection method, which includes two parts, a measurement scheme and measurement data processing.

[0071] 1. Multi-station simultaneous measurement scheme

[0072] 1) Use the reflector as the target mirror to be fixedly installed on the turntable of the machine tool through tooling. The initial center position of the target mirror is A 1 .

[0073] 2) Select the rotation center of the turntable as the origin of the coordinate system O, and the projection point from the initial center position of the target mirror to the turntable at the initial moment is A 1 ′ To OA 1 ′ Is the positive direction of the X axis, and the direction perpendicular to the face of the turntable through the O point is the positive direction of the Z axis, and the right-hand reference coordinate system O-XYZ of the measurement system is established.

[0074] 3) Put four laser trackers P j (j=1, 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com