Plastic particle heating and drying device

A technology of heating and drying plastic granules, which is applied in the direction of drying gas arrangement, drying of granular materials, drying of solid materials, etc. It can solve problems such as troublesome operation, high energy consumption, and inability to meet production and use, and achieve simple structure and efficient drying treatment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

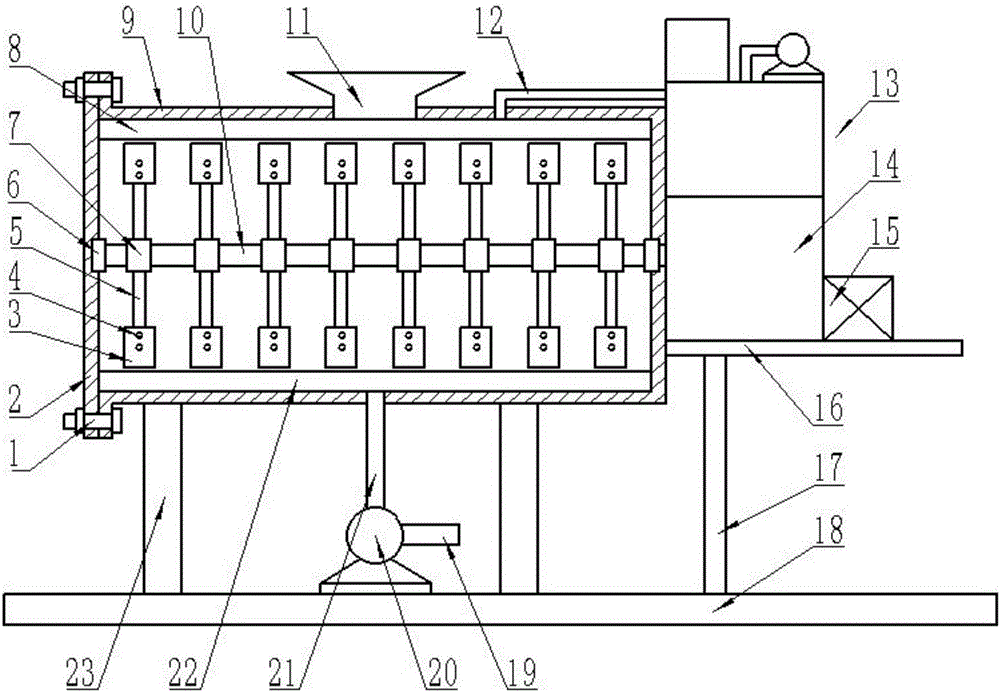

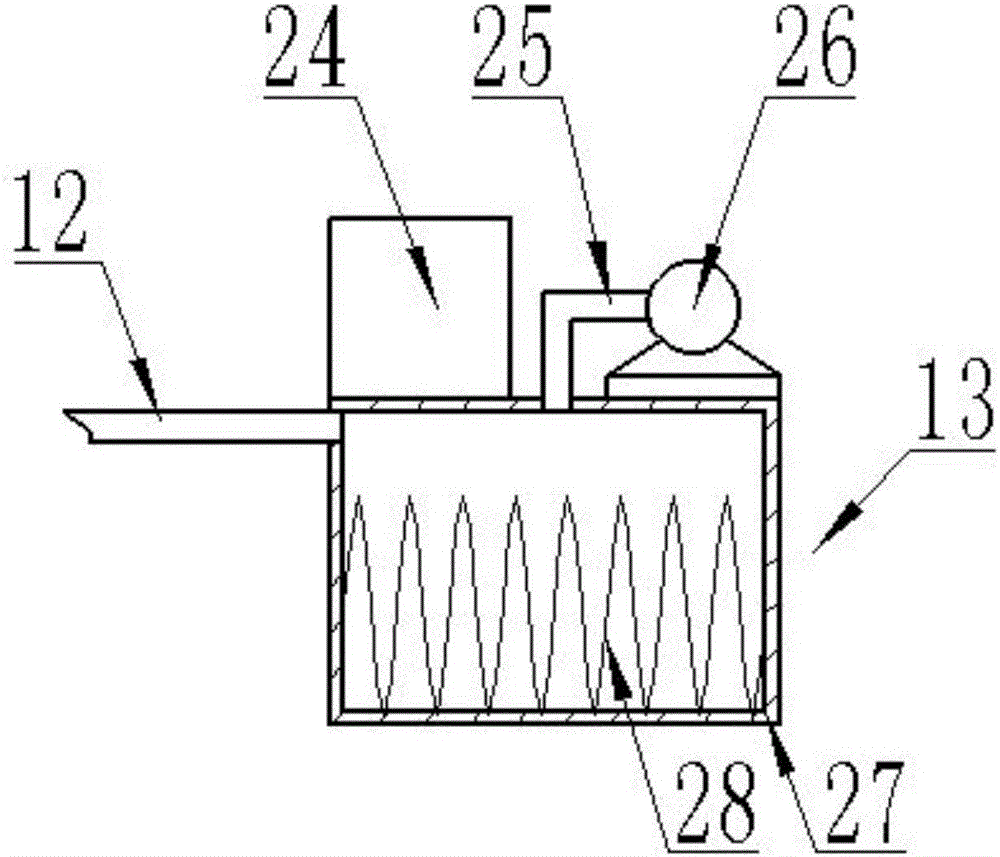

[0018] see Figure 1-4 , a heating and drying device for plastic particles, including a material stirring device and a dehumidification drying device; the material stirring device includes a bolt 1, a cover 2, a turning plate 3, a screw 4, a fixing rod 5, a bearing 6, a fixing sleeve 7, Processing cylinder 9, stirring shaft 10, feeding cylinder 11, transmission box 14, motor 15, fixed plate 16, support frame 17, base 18, support plate 23, transmission shaft 29, first transmission gear 30 and second transmission gear 31 The support plate 23 is provided with two pieces, which are welded on the base 18; the processing cylinder 9 is welded on the two support plates 23; the cover 2 is fixedly connected with the left side of the processing cylinder 9 by bolt 1, The bolt 1 is fixedly connected to facilitate disassembly and installation; the bearing 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com