Screw vacuum pump

A screw vacuum pump and screw technology, applied in pumps, rotary piston pumps, rotary piston machinery, etc., can solve the problems of low compression and reduced sealing area of screw vacuum pumps, and improve the sealing effect, compression ratio, and sealing effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

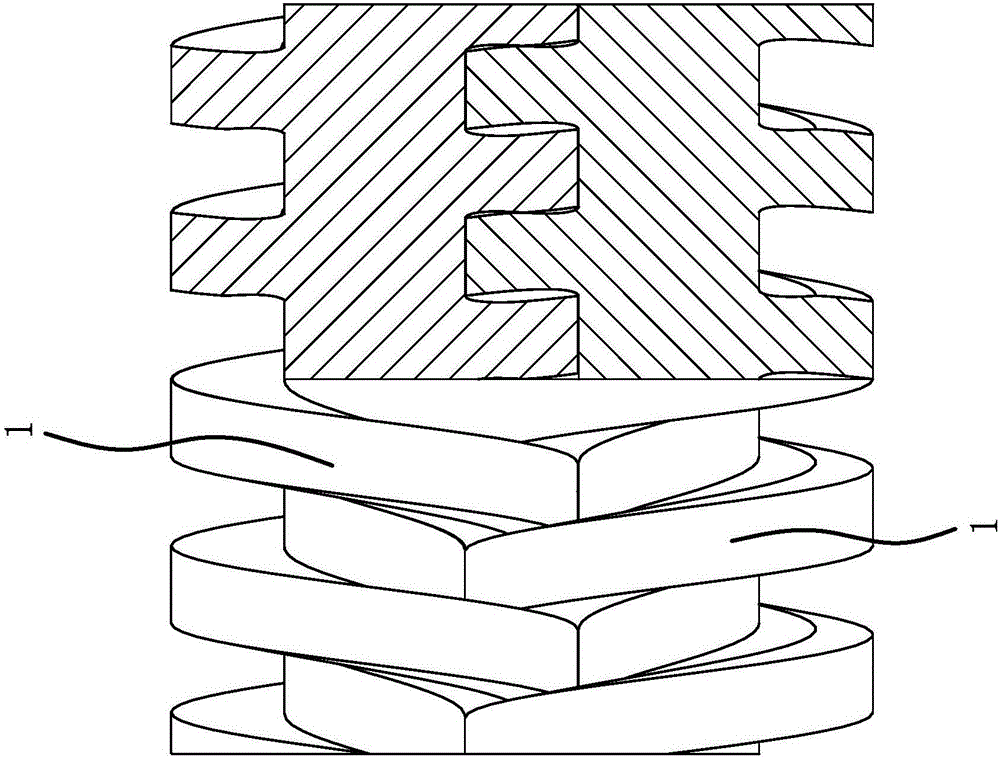

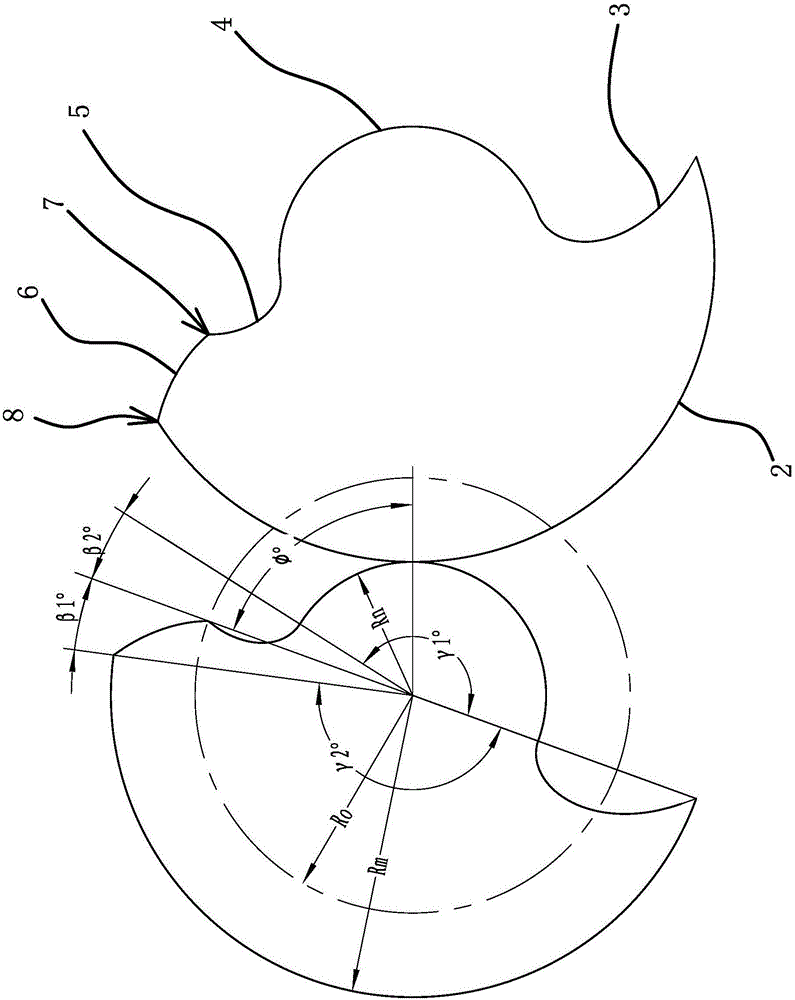

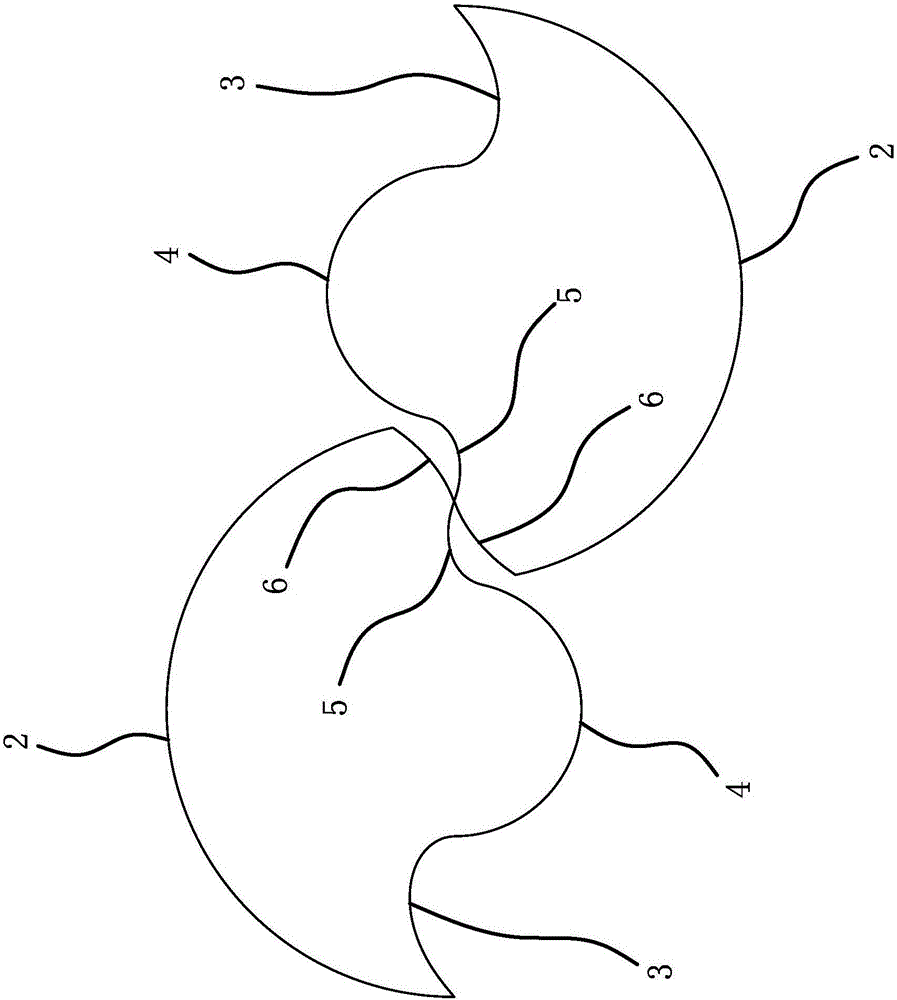

[0027] Such as Figure 1 to Figure 3 As shown, the screw vacuum pump includes two screws 1 with the same end profile and opposite rotation direction. The end profile of the screw 1 is composed of a section of addendum arc section 2, a section of cycloid section 3, and a section of dedendum circle section 4, which are sequentially connected. A section of cycloidal segment 5 and a segment of cycloidal segment 6 are composed, the segment of cycloidal segment 5 is a concave arc, the transition between segment of cycloidal segment 5 and root circle segment 4 is smooth, segment of cycloidal segment 5 and segment of node cycloid segment 6 are mutually Conjugate, the nodal cycloid segment 6 is an outwardly convex arc, the intersection of the nodal cycloid segment 5 and the nodal cycloid segment 6 forms a sharp angle 17, and the intersection of the nodal cycloid segment 6 and the addendum arc segment 2 forms a sharp angle 2 8; The equation for segment 5 of the cycloid is:

[0028] ...

Embodiment 2

[0038] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference lies in: the circular arc transition section is formed by rounding between the cycloid segment and the addendum arc segment, and the radius value range of the arc transition segment is: 0 ~0.2mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com