Pulse pump

A technology of pulse pump and pump body, applied in the direction of pumps, pump components, fuel injection pumps, etc., can solve the problems of nitrogen oxides not being reduced, waste, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

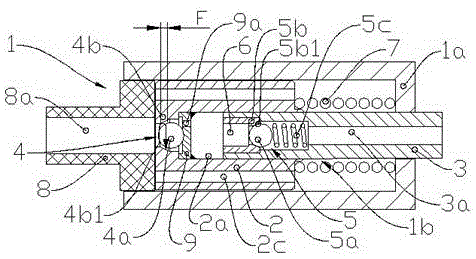

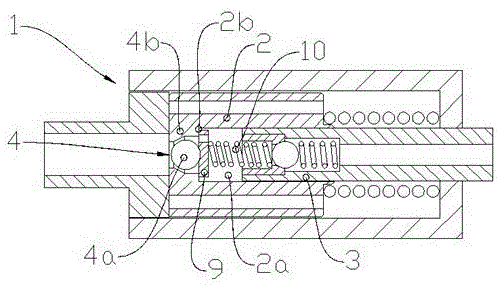

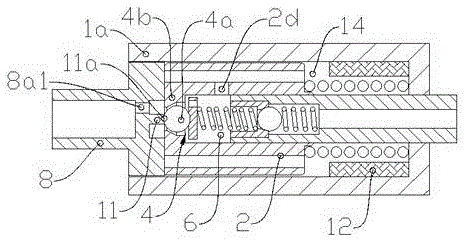

[0037] Such as figure 1As shown, it is one of the schematic diagrams of the embodiment of the pulse pump provided by the present invention. The pulse pump 1 includes the pump body 1a and the plunger pump 1b therein, the rear pump end 8 with the liquid inlet channel 8a and the return spring 7 . The plunger pump 1 b includes a sleeve 2 , a plunger 3 , an input valve 4 and an output valve 5 . The sleeve 2 and the plunger 3 form a pressure-feeding space 6, and the input valve 4 and the output valve 5 are respectively connected to the pressure-feeding space 6. The sleeve 2 includes a sleeve inner hole 2a, and the sleeve inner hole 2a closely fits with the outer surface of the plunger 3 and can slide freely. The plunger 3 is fixed on the pump body 1a, and the sleeve 2 can reciprocate along the plunger 3, causing the volume of the pressure-feeding space 6 to change alternately. The sleeve 2 is arranged with an axially through straight groove 2c to reduce the reciprocating motion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com