Portable double-layer coiled tubing sand pumping device and technology

A convenient, tubing technology, used in wellbore/well components, earth-moving drilling, etc., can solve the problems of affecting gas production, easy wear, difficult installation, etc., achieving good working stability, easy installation and use, sand pumping Efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

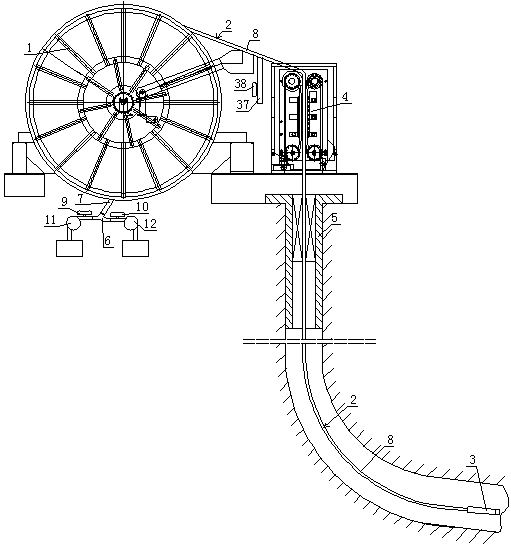

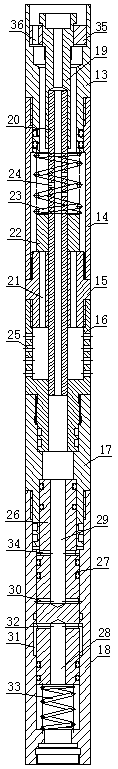

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

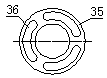

[0017] Such as Figure 1 to Figure 3 As shown, the portable double-layer coiled tubing sand pumping device of the embodiment of the present invention includes a drum 1, a motor and a reducer (not shown) as a driving device, a coiled tubing 2 wound on the drum 1, and a coiled tubing for conveying Injection head 4, blowout preventer 5 placed at the wellhead, sand washing nozzle 3; coiled tubing 2 includes inner pipe 7 and outer pipe 8, the space between the inner pipe 7 and the outer pipe 8 is an annulus, and the rear end of the annulus passes through the outer The tube 8 covers the inner tube 7 and closes; the rear end of the inner tube 7 is located outside the outer tube 8, and the rear end of the inner tube 7 is connected with a three-way joint 6, and the two inlet pipes of the three-way joint 6 are provided with control valves 9 and 10 , one inlet pipe is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com