Assembly type energy-saving thermal-insulation composite wall board and making method thereof

A technology of thermal insulation compounding and manufacturing method, applied in thermal insulation, walls, building components and other directions, can solve the problems of poor energy saving and thermal insulation effect, difficult construction, and non-compliance with the construction requirements of prefabricated buildings, so as to achieve simple construction operations and lighten wall Self-weight, enhancing the effect of heat preservation and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution will be described in detail below in conjunction with the drawings and specific implementations.

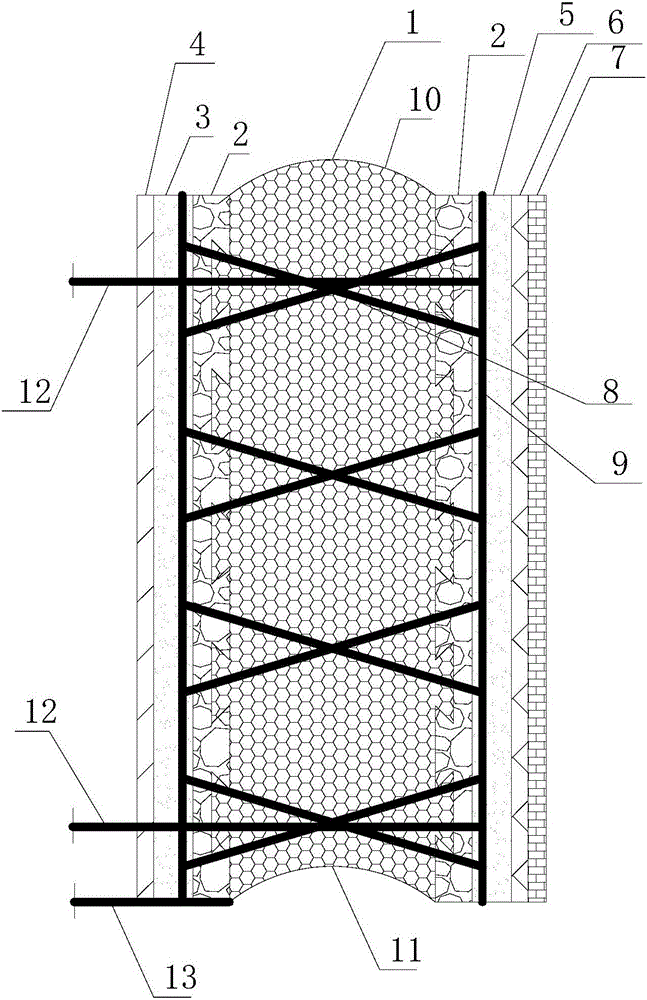

[0040] As shown in the figure, a fabricated energy-saving and thermal insulation composite wall panel includes an intermediate thermal insulation layer 1 and a steel wire mesh frame. The two sides of the thermal insulation layer 1 are provided with an inner wall layer and an outer wall layer, and the steel wire mesh frame includes a diagonal Insert wires 8 and steel mesh sheets 9, the oblique insert wires 8 penetrate through the insulation layer 1 and are fixedly connected to the steel mesh sheets 9 arranged in the inner wall layer and the outer wall layer, and the inner wall layers are respectively arranged from the indoor to the outdoor direction Mixed mortar layer 4, light mortar layer 3, interface mortar layer 2. The outer wall layer is provided with interface mortar layer 2, thermal insulation mortar layer 5, and polymer plastering mortar composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com