A vertical wall sliding installation support device and its construction method

A technology for sliding installation and support device, applied in the field of civil engineering, can solve the problems of complex situation, complex road structure, increase the operating cost of wheeled cranes, etc., and achieve the effects of cost saving, convenient installation and assembly operations, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

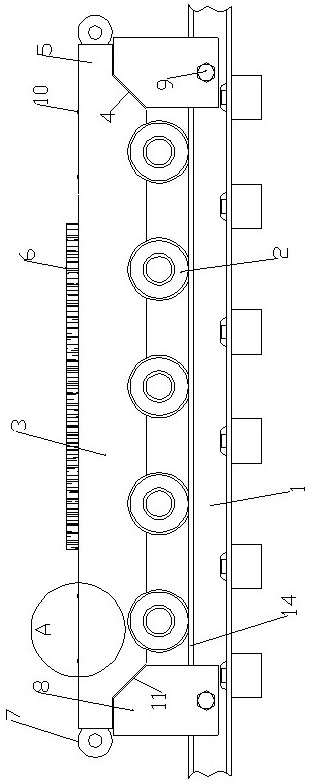

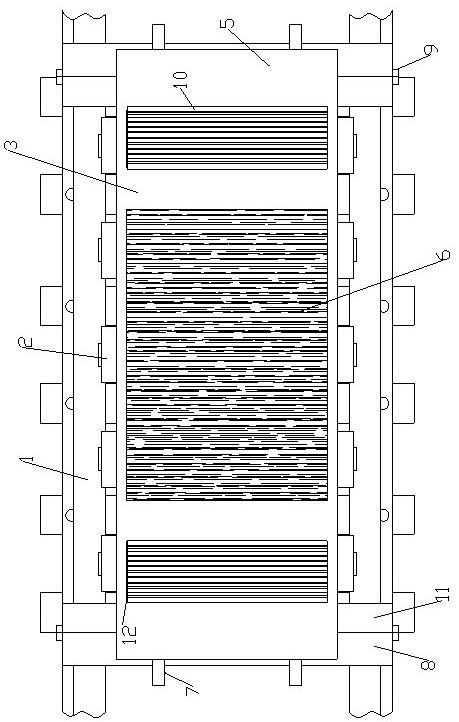

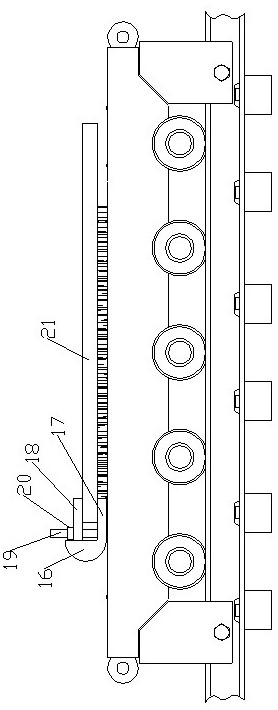

[0025] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, a vertical wall sliding installation support device includes a translation trolley 3 installed on the translation track 1 through track wheels 2, and the bottoms at both ends of the translation trolley 3 All are provided with inclined retaining grooves 4, and the outer ends of the translation trolley 3 outside the inclined retaining grooves 11 are fixedly equipped with reinforced support seats 5, and the center position of the top surface of each reinforced support seat 5 is provided with a displacement rotation groove 12, and the displacement rotation The groove 12 is a groove-like structure with a semicircular cross section. A number of rollers 10 are movably installed on the inner wall of the displacement rotation groove 12 in the length direction. Raise the anti-skid support layer 6, a rotating support device is movably installed on at least one side of the raised anti-skid support layer 6, and a bottom limit support blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com