Improved pouring draught fan foundation pit

An improved and foundation pit technology is applied in the field of fan foundation pit and improved pouring fan foundation pit, which can solve the problems of large concrete slump, concrete waste, and reduce concrete water-cement ratio, so as to ensure the pouring quality and increase flexibility. performance, improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

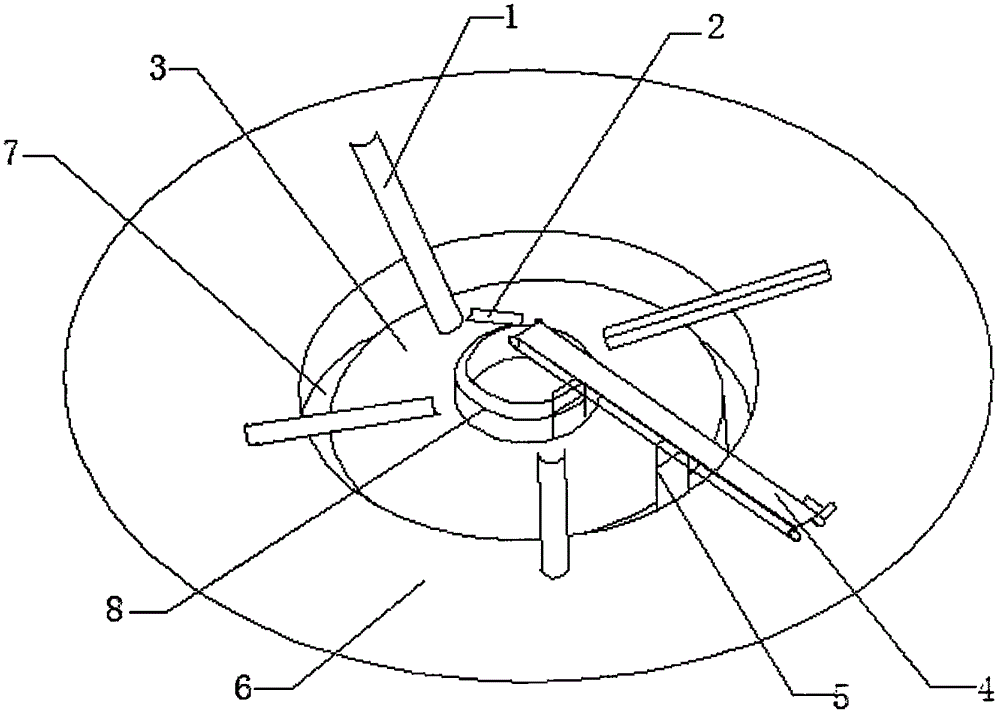

[0014] Such as figure 1 As shown, the improved pouring fan foundation pit of the present invention includes a foundation pit 6 and a template 7 installed in the foundation pit 6; the template 7 is constructed by a plurality of steel bars (not shown); the foundation pit 6 is provided with a foundation 3 in the center; a foundation ring 8 is provided in the center of the foundation 3; a steel pipe (not shown) of the same height as the template 7 is welded to the edge of the template 7; a door-type bracket 5 is installed on the steel pipe; A belt conveyor 4 is installed between the door-shaped bracket 5 and the base ring 8; four long chutes 1 are arranged between the foundation pit 6 and the base ring 8; the belt conveyor 4 has a short Chute 2.

[0015] The belt conveyor 4 is hoisted to the door-shaped bracket 5 by a crane, and the front end of the belt conveyor 4 is set in the center of the foundation ring 8, and the end of the belt conveyor 4 is set at a position not less than 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com