A large-span support system for a subway foundation pit and its construction method

A support system and large-span technology, which is applied in infrastructure engineering, excavation, artificial islands, etc., can solve the problems of small support span, low construction efficiency and low structural strength of foundation pits, and achieve large construction work space and high construction efficiency. , the effect of speeding up the excavation work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

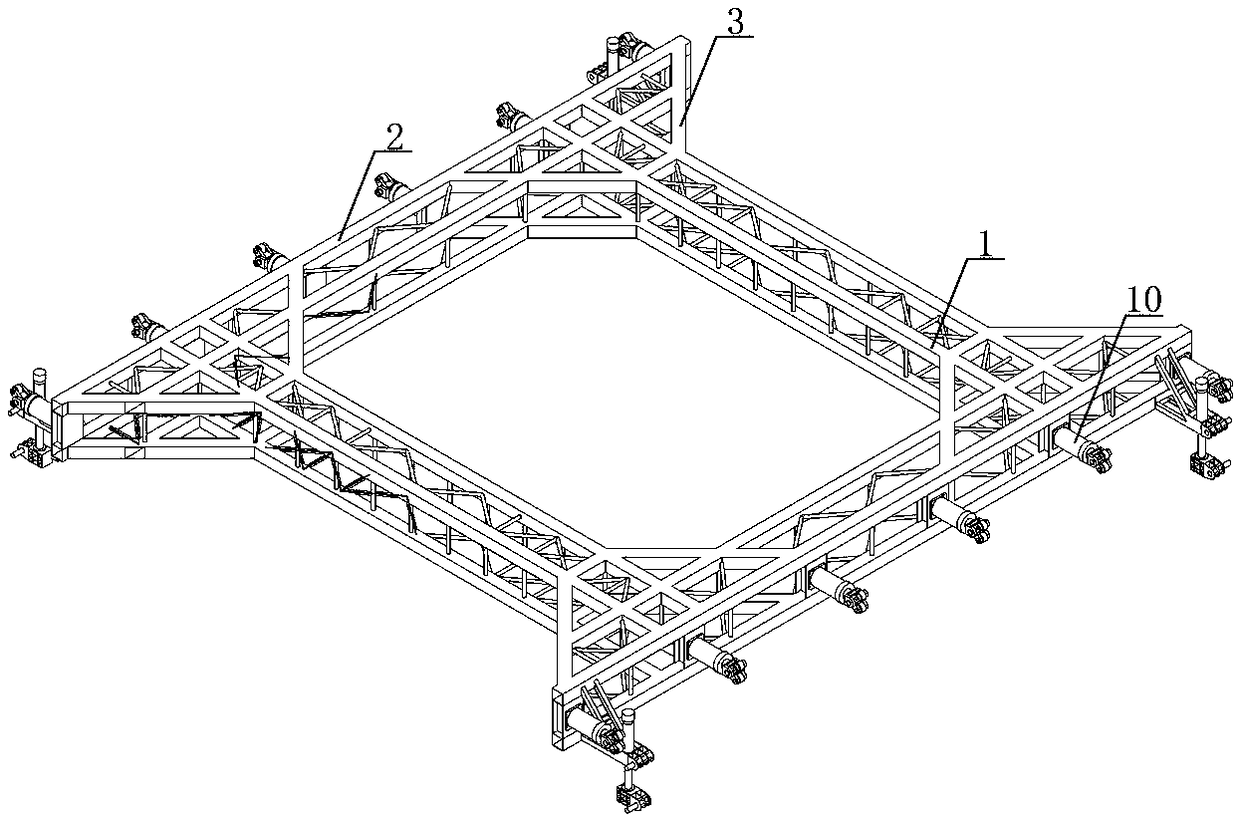

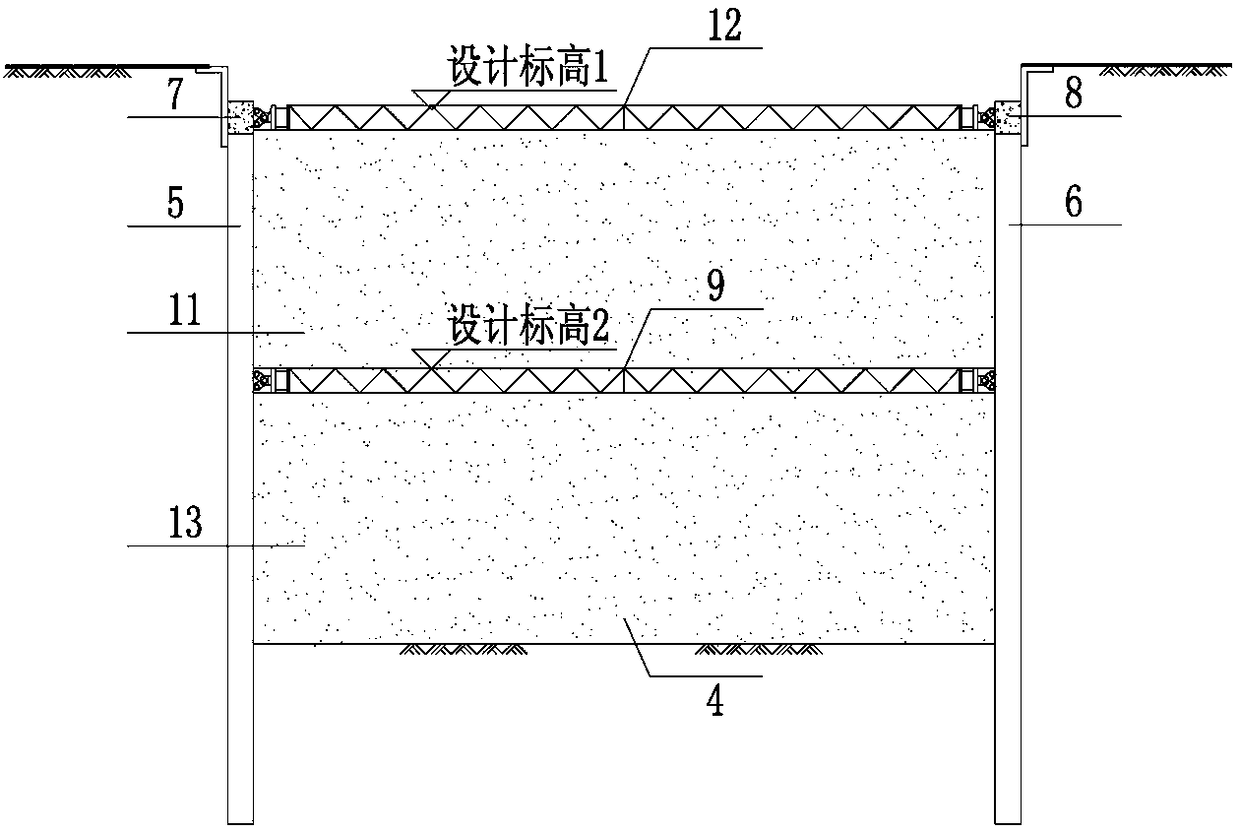

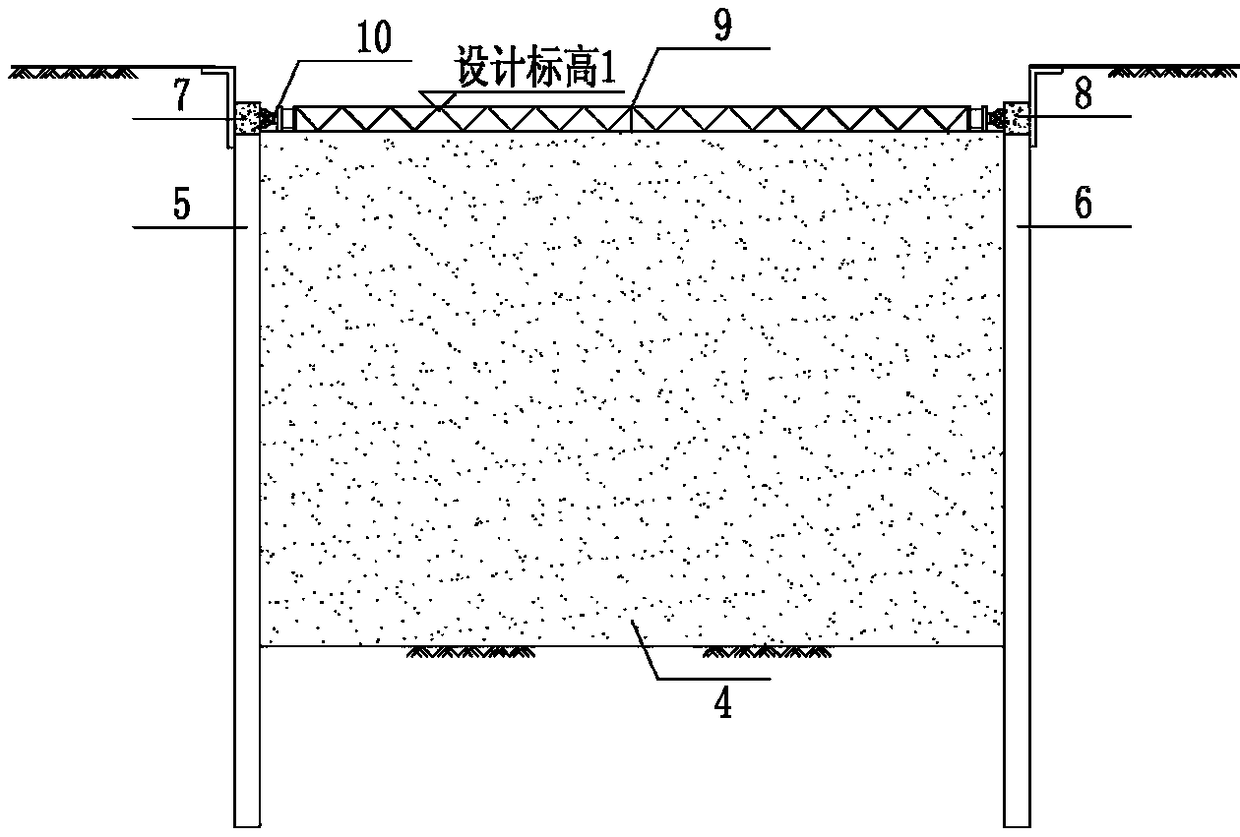

[0044] Examples see figure 1 As shown, in this example, the dimensions of the two directions of the subway foundation pit are 18m and 23m respectively; within the range of the support system, a clearance range of about 13m×16m is formed, and the medium-sized backhoe excavator can directly operate within this range. Compared with the conventional internal support, the excavation range is expanded, and the construction efficiency of the subway foundation pit can be improved. After the earthwork is excavated, the horizontal truss support system is quickly lowered to the design elevation through the lifting power mechanism, which improves the efficiency of support installation.

[0045] This large-span support system for a subway foundation pit includes horizontal truss support units horizontally supported between the underground diaphragm walls of the foundation pit. The truss support unit includes an upper plane truss support, a lower plane truss support and a connecting rod ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com