A kind of steel-cement mixing pile inner support structure and support method thereof

A technology for cement-soil mixing piles and supporting structures, which is applied in basic structure engineering, excavation, sheet pile walls, etc., can solve the problems of limited construction space, inability to implement, and increase construction period, so as to increase the construction work space and shorten the construction period. The effect of construction period and saving engineering quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawings and examples.

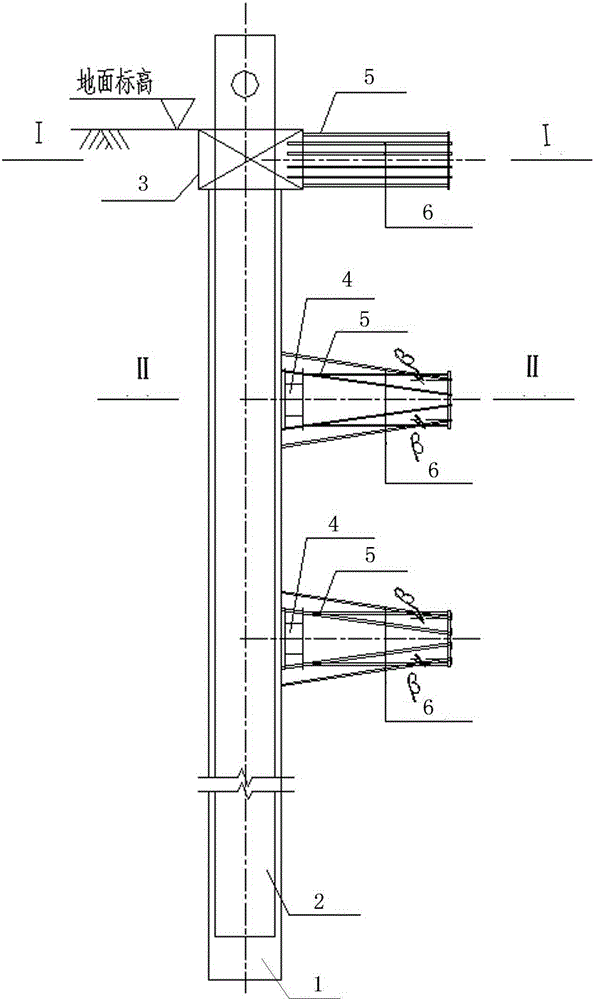

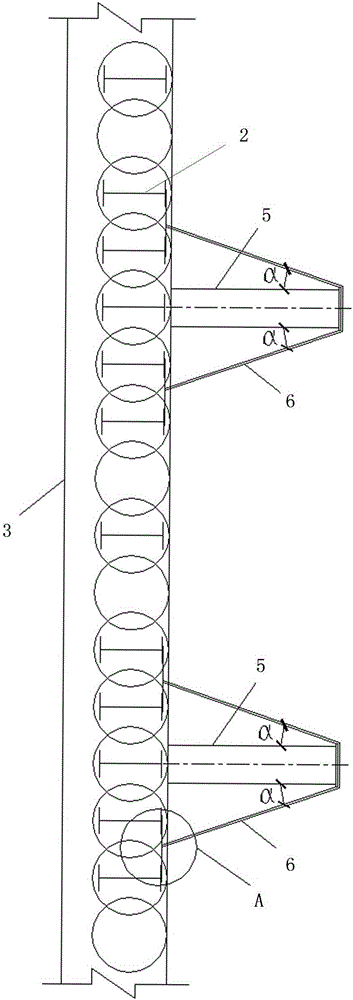

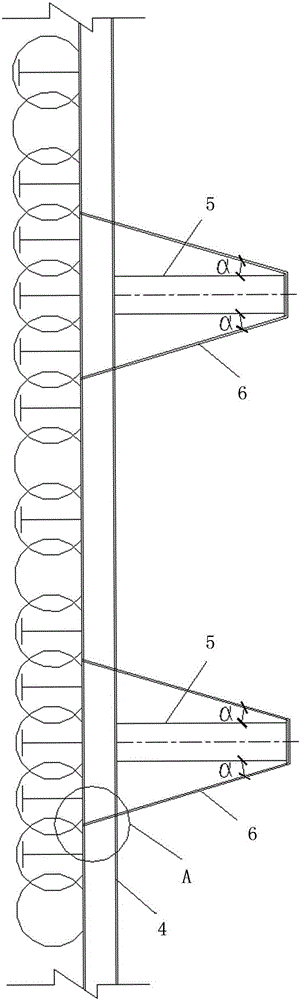

[0017] As shown in the figure, the steel-cement-soil mixing pile includes a cement-soil mixing pile. The cement-soil mixing pile 1 is provided with an embedded steel 2, and a support box 5 is set at the top ring beam 3 and the steel purlin 4 of the steel-cement-soil mixing pile. , one end of the support box is connected to the top ring beam or steel purlin of the shaped steel cement-soil mixing pile, and the other end of the support box is connected to the panel 7 through the steel strand 6, and the panel 7 is connected to two adjacent interpolated steel 2 Phase welding. The support box is arranged horizontally, the steel strands are arranged in pairs on both sides of the center line of the support box, the steel strands connected to the support box at the top ring beam are arranged horizontally, and the horizontal plane at the support box at the steel purlin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com