On-line detection device for process liquid parameters of batch dyeing machine

A technology of detection device and process fluid, applied in textile processing machine accessories, equipment configuration for processing textile materials, textiles and papermaking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

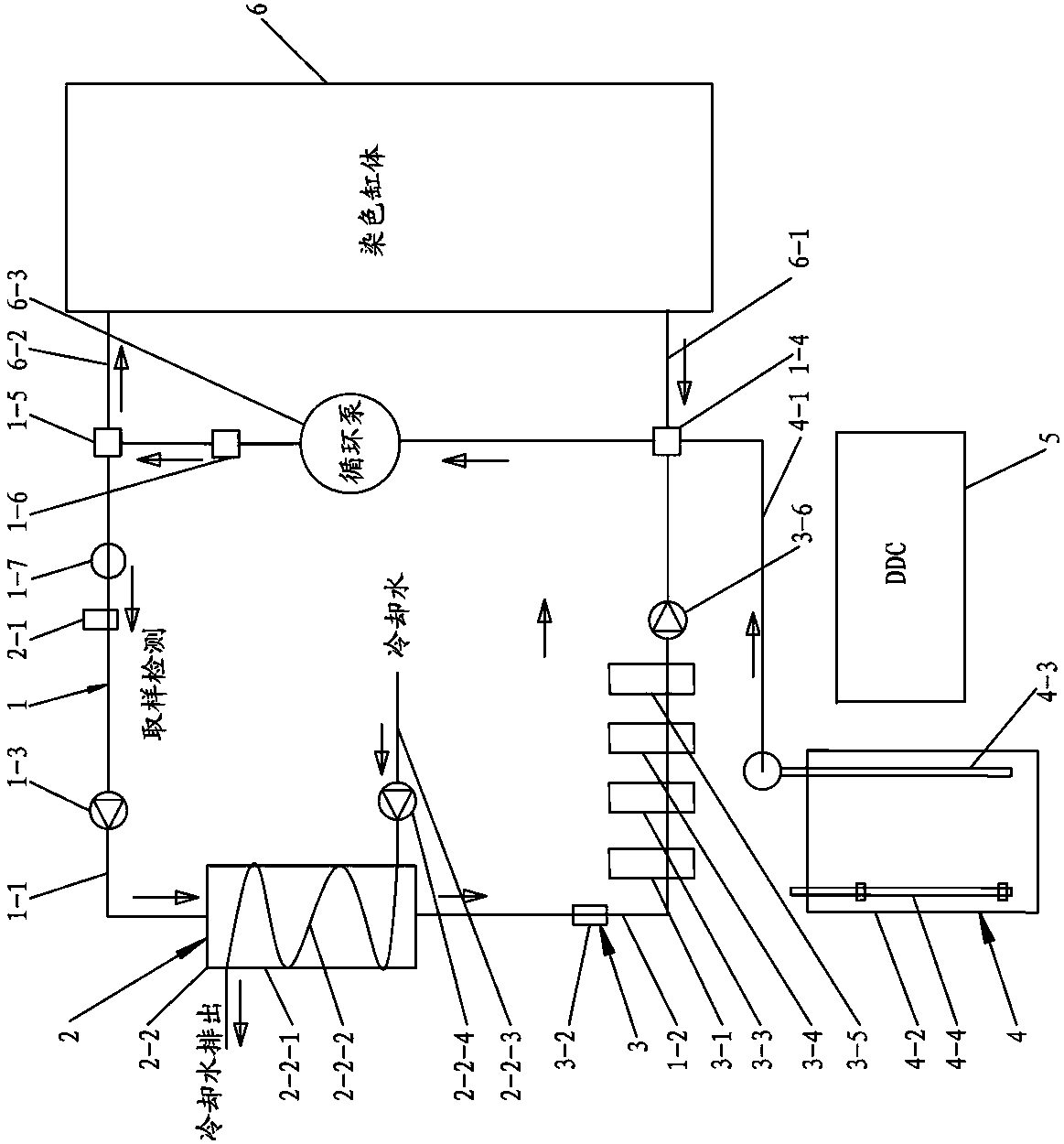

[0040] like figure 1 As shown, an on-line detection device for process liquid parameters of an intermittent dyeing machine includes a dyeing cylinder 6, a first communicating pipe 6-1, a second communicating pipe 6-2 and a circulation pump 6-3, and the first communicating pipe One end of 6-1 and one end of the second communicating pipe 6-2 communicate with the dyeing vat 6 respectively, the inlet of the circulation pump 6-3 communicates with the first communicating pipe 6-1, and the outlet of the circulating pump 6-3 communicates with the first communicating pipe 6-1. The second connecting pipe 6-2 is connected;

[0041] It also includes a process liquid sampling unit 1, a sample cooling unit 2, a sample detection unit 3 and a control and data processing unit 5;

[0042] The process liquid sampling unit 1 includes a sampling pipe 1-1 and a sample return pipe 1-2, and one end of the sampling pipe 1-1 is simultaneously connected with the other end of the second communication pi...

Embodiment 2

[0060] like figure 1 As shown, the difference between Embodiment 2 and Embodiment 1 is: an on-line detection device for process liquid parameters of an intermittent dyeing machine, including a dyeing cylinder 6, a first communicating pipe 6-1, and a second communicating pipe 6-2 And circulation pump 6-3, one end of the first communication pipe 6-1 and one end of the second communication pipe 6-2 are respectively connected with the dyeing vat 6, and the inlet of the circulation pump 6-3 is connected with the first communication pipe 6. -1 is connected, and the outlet of the circulating pump 6-3 is connected with the second connecting pipe 6-2;

[0061] It also includes a process liquid sampling unit 1, a sample cooling unit 2, a sample detection unit 3 and a control and data processing unit 5;

[0062] The process liquid sampling unit 1 includes a sampling pipe 1-1 and a sample return pipe 1-2, and one end of the sampling pipe 1-1 is simultaneously connected with the other end...

Embodiment 3

[0069] like figure 1 As shown, the difference between embodiment 3 and embodiment 1 is: an on-line detection device for process liquid parameters of an intermittent dyeing machine, including a dyeing cylinder 6, a first communicating pipe 6-1, and a second communicating pipe 6-2 And circulation pump 6-3, one end of the first communication pipe 6-1 and one end of the second communication pipe 6-2 are respectively connected with the dyeing vat 6, and the inlet of the circulation pump 6-3 is connected with the first communication pipe 6. -1 is connected, and the outlet of the circulating pump 6-3 is connected with the second connecting pipe 6-2;

[0070] It also includes a process liquid sampling unit 1, a sample cooling unit 2, a sample detection unit 3 and a control and data processing unit 5;

[0071] The process liquid sampling unit 1 includes a sampling pipe 1-1 and a sample return pipe 1-2, and one end of the sampling pipe 1-1 is simultaneously connected with the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com