Safety explosion-proof device and working method for continuous monitoring of material fermentation

An explosion-proof device and material technology, applied in biochemical cleaning devices, biochemical equipment and methods, enzymology/microbiology devices, etc., can solve the problems of foreign matter obstructing the observation line of sight, use safety cannot be judged, etc., and achieve convenient stirring time , prolong the time of fermentation and gas production, and prevent the generation of fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

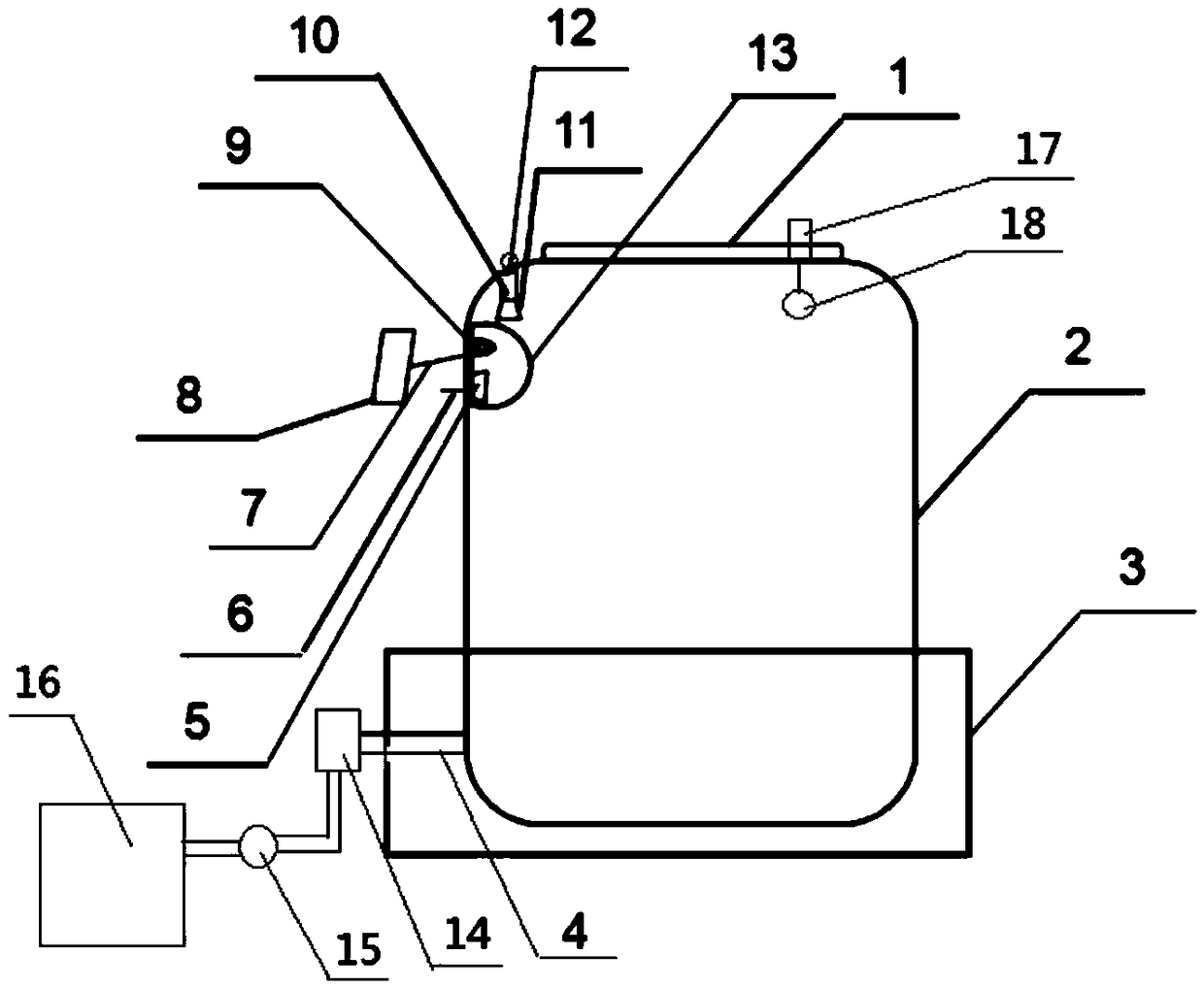

[0022] A safety explosion-proof device for continuously monitoring material fermentation, comprising a fermenter 2, a sealing cover 1 is installed at the center of the top of the fermenter 2, a heating belt 3 is installed at the bottom of the fermenter 2, and the fermenter 2 A pressure valve 12 is installed on the left side of the top, the pressure valve 12 is connected to the water inlet pipe 10, the water inlet pipe 10 is connected to the nozzle 11, and the bottom left side of the fermenter 2 is equipped with a feed pipe 4 , the feed pipe 4 passes through the heating belt 3 and is connected to the flow meter 14, the flow meter 14 is connected to the feed pump 15 through the pipeline, and the feed pump 15 is connected to the feed tank 16, The upper left side of the fermenter 2 is equipped with a sealing glass cover 13, inside the sealing glass cover 13 is fixed a heating fan 5 and a lighting probe 9, the lighting probe 9 is connected to an external wire 7, and the The externa...

specific Embodiment approach 2

[0025] A safety explosion-proof device for continuously monitoring material fermentation, comprising a fermenter 2, a sealing cover 1 is installed at the center of the top of the fermenter 2, a heating belt 3 is installed at the bottom of the fermenter 2, and the fermenter 2 A pressure valve 12 is installed on the left side of the top, the pressure valve 12 is connected to the water inlet pipe 10, the water inlet pipe 10 is connected to the nozzle 11, and the bottom left side of the fermenter 2 is equipped with a feed pipe 4 , the feed pipe 4 passes through the heating belt 3 and is connected to the flow meter 14, the flow meter 14 is connected to the feed pump 15 through the pipeline, and the feed pump 15 is connected to the feed tank 16, The upper left side of the fermenter 2 is equipped with a sealing glass cover 13, inside the sealing glass cover 13 is fixed a heating fan 5 and a lighting probe 9, the lighting probe 9 is connected to an external wire 7, and the The externa...

specific Embodiment approach 3

[0028] A safety explosion-proof device for continuously monitoring material fermentation, comprising a fermenter 2, a sealing cover 1 is installed at the center of the top of the fermenter 2, a heating belt 3 is installed at the bottom of the fermenter 2, and the fermenter 2 A pressure valve 12 is installed on the left side of the top, the pressure valve 12 is connected to the water inlet pipe 10, the water inlet pipe 10 is connected to the nozzle 11, and the bottom left side of the fermenter 2 is equipped with a feed pipe 4 , the feed pipe 4 passes through the heating belt 3 and is connected to the flow meter 14, the flow meter 14 is connected to the feed pump 15 through the pipeline, and the feed pump 15 is connected to the feed tank 16, The upper left side of the fermenter 2 is equipped with a sealing glass cover 13, inside the sealing glass cover 13 is fixed a heating fan 5 and a lighting probe 9, the lighting probe 9 is connected to an external wire 7, and the The externa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com