Flow guide type coke oven leaking smoke collection device and method

A soot collection and coke oven technology, which is applied in coking ovens, soot removal, chemical instruments and methods, etc., can solve the problems of long-term accumulated pollution, escape, and gas release in the environment, and achieve the effect of improving the efficiency of soot collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

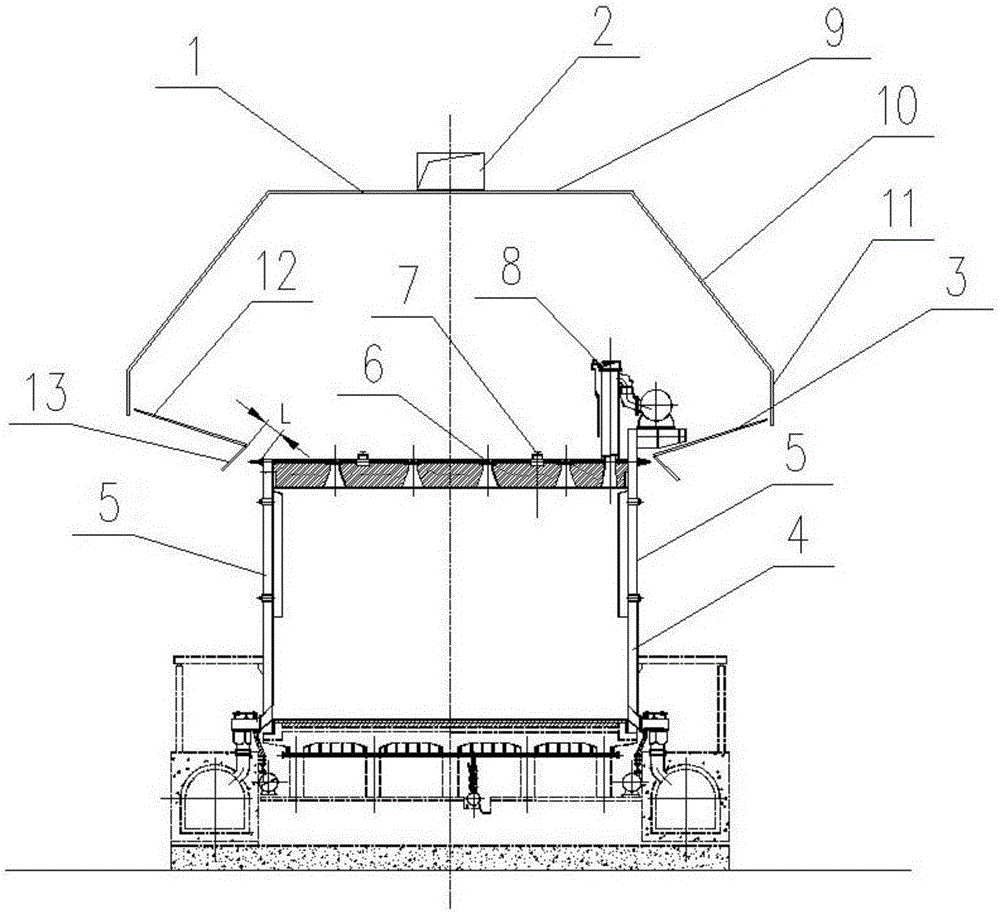

[0028] Such as figure 1 As shown, a diversion type coke oven fugitive dust collection device according to the present invention includes a dust collection cover 1 and a windproof adjustment device 3; the dust collection cover 1 is arranged above the coke oven 4, and its projected area covers And larger than the projected area of the coke oven 4, the center of the top of the dust collection cover 1 is provided with a flue gas conveying pipe 2 connected to the external smoke purification treatment equipment; In the annular space of the wind speed regulating plate 12, the adjusting mechanism and the lower air flow baffle 13, the bottom of the wind speed regulating plate 12 is connected with the top of the lower air flow baffle 13; The mechanism is used to adjust the porosity of the wind speed regulating plate 12; the height of the upper edge of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com