Fly ash modification agent and modified low-quality fly ash active mixing material thereof

A technology of fly ash and modifier, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of limited effect, insufficient output of high-quality fly ash, high cost, etc., to improve early and Late strength, improving the effect of increasing shortage of resources, improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

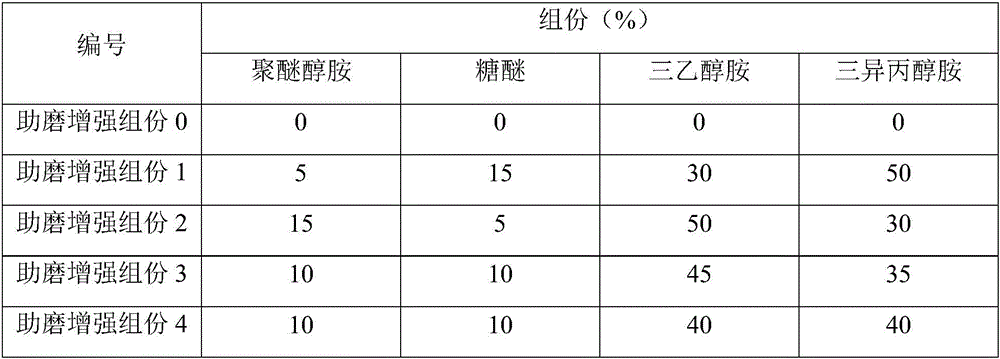

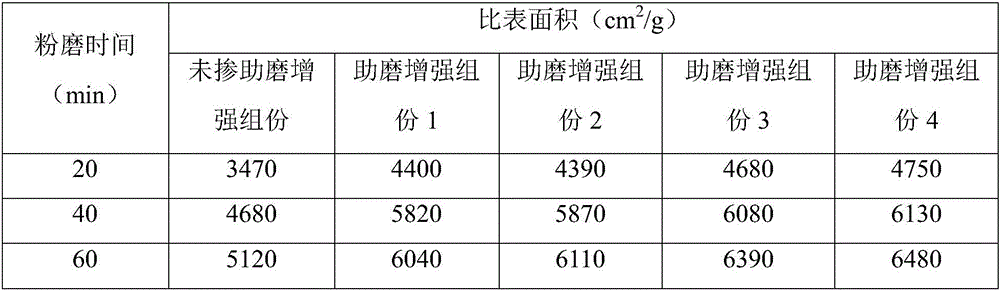

[0032] A fly ash modifier, which comprises the following components in parts by mass: 75 parts of red mud, 25 parts of phosphogypsum, and 0.1 part of a grinding aid strengthening component; the grinding aid strengthening component is polyether alcohol 5-15 parts of amine, 5-15 parts of sugar ether, 30-50 parts of triethanolamine, 30-50 parts of triisopropanolamine. The specific components are shown in Table 1. Dry the above-mentioned red mud and phosphogypsum at 105°C and mix them evenly to obtain a mixture; then, according to the ratio of the grinding-aiding strengthening components in Table 1, respectively mix the grinding-aiding strengthening components 0 to 4 (the grinding-aiding strengthening component 0 corresponds to In the case of not mixing the grinding aid strengthening component in Table 2) into the obtained mixture, then place them in a ball mill respectively, grind for 20-60min, and measure the specific surface area in different grinding time, see Table 2.

[0033...

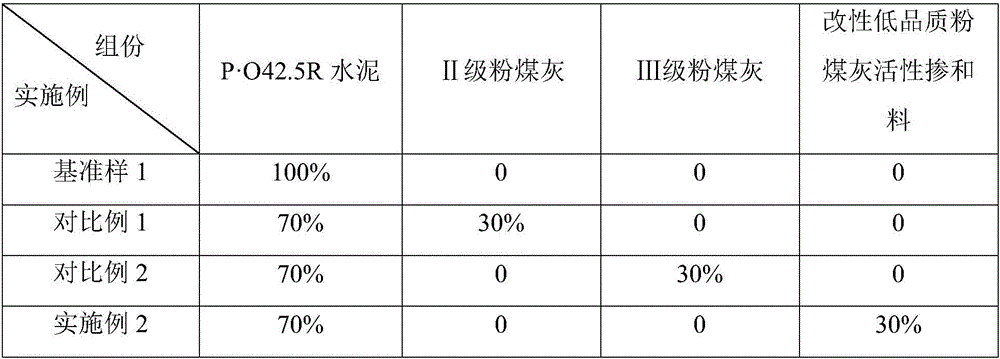

Embodiment 2

[0039] A fly ash modifier, which comprises the following components in parts by mass: 75 parts of red mud, 25 parts of phosphogypsum, and 0.1 part of a grinding aid strengthening component; both the red mud and phosphogypsum are baked The mass after drying: the grinding aid reinforcing component is composed of 10wt% polyetherolamine, 10wt% sugar ether, 45wt% triethanolamine and 35wt% triisopropanolamine according to mass percentage.

[0040] The preparation method of above-mentioned fly ash modifier, it comprises the steps:

[0041] (1) After drying red mud and phosphogypsum, set aside;

[0042](2) According to the mass fraction of each raw material, take the following components: 75 parts of red mud, 25 parts of phosphogypsum, and 0.1 part of grinding aid strengthening component; Ether alcohol amine 10wt%, sugar ether 10wt%, triethanolamine 45wt% and triisopropanolamine 35wt%; wherein, the quality of red mud and phosphogypsum is based on the mass after drying;

[0043] (3) ...

Embodiment 3

[0057] A fly ash modifier, which comprises the following components in parts by mass: 80 parts of red mud, 20 parts of phosphogypsum, and 0.2 part of a grinding aid strengthening component; both the red mud and phosphogypsum are baked The mass after drying: the grinding aid strengthening component is composed of 10wt% polyetherolamine, 10wt% sugar ether, 40wt% triethanolamine and 40wt% triisopropanolamine according to mass percentage.

[0058] Above-mentioned fly ash modifier preparation method, it comprises the steps:

[0059] (1) After red mud and phosphogypsum are dried, set aside;

[0060] (2) According to the mass fraction of each raw material, the following components are weighed: 80 parts of red mud, 20 parts of phosphogypsum, and 0.2 part of grinding aid strengthening component; 10wt% ether alcohol amine, 10wt% sugar ether, 40wt% triethanolamine and 40wt% triisopropanolamine; wherein, the quality of red mud and phosphogypsum is based on the mass after drying;

[0061...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com