Organic wastewater biochemical effluent ozone advanced treatment device and treatment method

A technology of organic wastewater and biochemical effluent, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of high investment and operating costs of the ozone oxidation device and treatment method, large area occupied by the ozone oxidation device, and low ozone utilization rate, etc., to achieve Increased treatment effect, ease of handling, effect of increased ozone solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1: Treatment of landfill leachate biochemical effluent

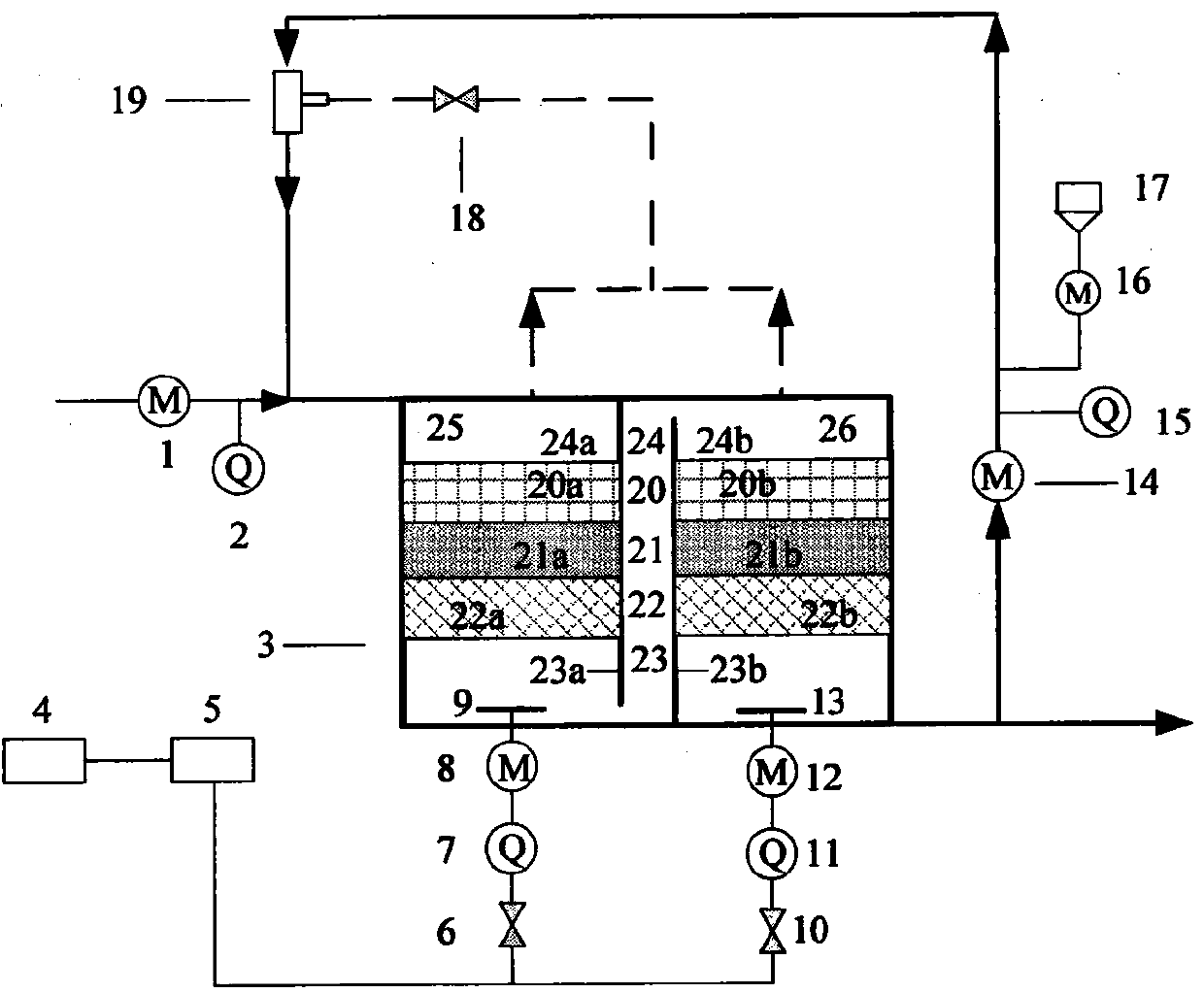

[0052] Such as figure 1 As shown, an organic wastewater biochemical effluent ozone advanced treatment device includes an ozone oxidation unit, an ozone supply unit, a wastewater circulation unit, and an ozone tail gas recovery unit.

[0053] Described ozone oxidation unit comprises airtight ozone oxidizer 3, and described ozone oxidizer 3 comprises the first oxidation chamber 25, the second oxidation chamber 26 and is located between the first oxidation chamber 25 and the second oxidation chamber 26 Intermediate partition 23, said intermediate partition 23 comprises a first oxidation chamber partition 23a positioned at one side of the first oxidation chamber 25 and a second oxidation chamber partition 23b positioned at one side of the second oxidation chamber 26, the first oxidation chamber The chamber 25 and the second oxidation chamber 26 are separated by an intermediate partition 23 , and the first oxi...

Embodiment 2

[0075] Example 2: Treatment of biochemical effluent from papermaking wastewater

[0076] Such as figure 1 As shown, an organic wastewater biochemical effluent ozone advanced treatment device includes an ozone oxidation unit, an ozone supply unit, a wastewater circulation unit, and an ozone tail gas recovery unit.

[0077]Described ozone oxidation unit comprises airtight ozone oxidizer 3, and described ozone oxidizer 3 comprises the first oxidation chamber 25, the second oxidation chamber 26 and is located between the first oxidation chamber 25 and the second oxidation chamber 26 Intermediate partition 23, said intermediate partition 23 comprises a first oxidation chamber partition 23a positioned at one side of the first oxidation chamber 25 and a second oxidation chamber partition 23b positioned at one side of the second oxidation chamber 26, the first oxidation chamber The chamber 25 and the second oxidation chamber 26 are separated by an intermediate partition 23 , and the ...

Embodiment 3

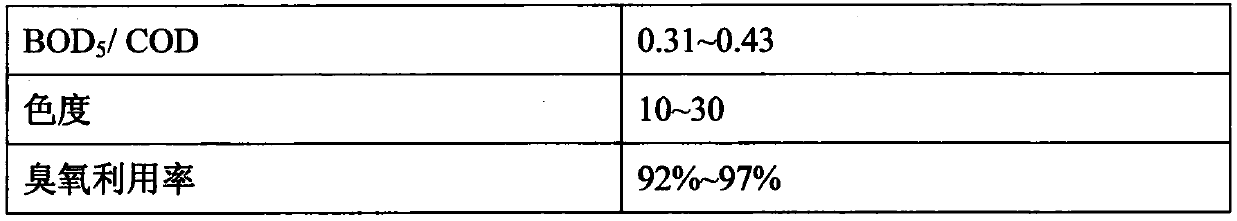

[0099] Example 3: Treatment of printing and dyeing wastewater biochemical effluent

[0100] Such as figure 1 As shown, an organic wastewater biochemical effluent ozone advanced treatment device includes an ozone oxidation unit, an ozone supply unit, a wastewater circulation unit, and an ozone tail gas recovery unit.

[0101] Described ozone oxidation unit comprises airtight ozone oxidizer 3, and described ozone oxidizer 3 comprises the first oxidation chamber 25, the second oxidation chamber 26 and is located between the first oxidation chamber 25 and the second oxidation chamber 26 Intermediate partition 23, said intermediate partition 23 comprises a first oxidation chamber partition 23a positioned at one side of the first oxidation chamber 25 and a second oxidation chamber partition 23b positioned at one side of the second oxidation chamber 26, the first oxidation chamber The chamber 25 and the second oxidation chamber 26 are separated by an intermediate partition 23 , and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com