Bionic passive rebound mechanical leg

A technology of mechanical legs and fuselage, applied in the field of robotics, can solve problems such as low energy utilization, failure to operate normally, damage to machine parts, etc., and achieve the effects of low cost, stable work, and large carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

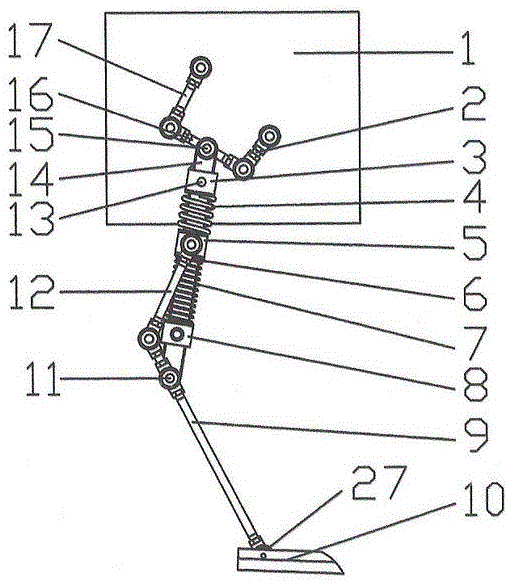

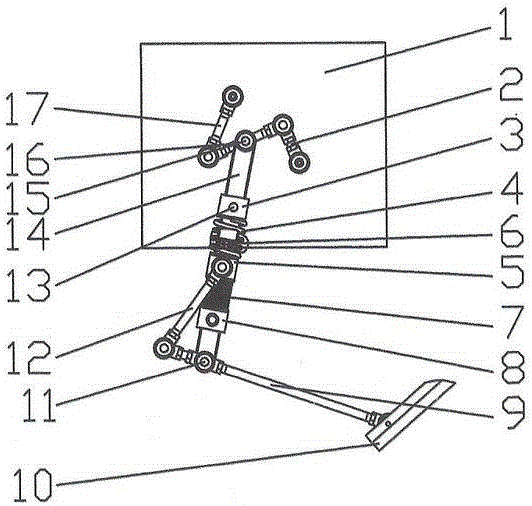

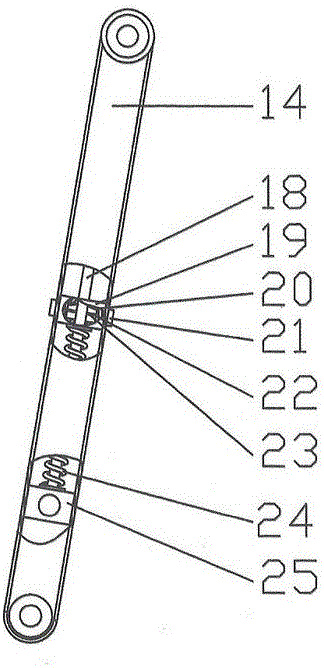

[0018] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a fuselage 1, a crank linkage mechanism, a passive rebound mechanism and a foot end; the crank linkage mechanism includes a crank 2, a femur 16 and a rocker 17; , upper outer spring 4, pulley 26, movable slider 5, fibula 12, lower outer spring 7, block 8, metatarsal bone 9, pin shaft 11 and inner spring mechanism 6, wherein inner spring mechanism 6 includes base 25, inner shaft 18 , compression spring plate 21, compression spring plate base 19, baffle plate 27, small spring 23, small spring guide rod 22, brake line 20; Foot end comprises torsion spring 28 and toe 10, and toe 10 is made of flexible energy storage material production.

[0019] The fixed slider 3 in the passive rebound mechanism is fixed on the fuselage 1, and the tibia 14 and the fixed slider 3 form a sliding pair; the pulley 26 is fixed on the tibia 14; the upper outer spring 4 and the lower outer spring 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com