Hydraulic interconnected suspension system for preventing pitching and rolling from crossing, lifting and twisting

A hydraulic interconnection suspension and cross-lifting technology, which is applied in the interconnection system, suspension, transportation and packaging, etc., can solve problems such as easy damage, rollover accidents, front and rear pitching, etc., achieve remarkable results, reduce costs, and improve ride comfort sexual and manipulative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

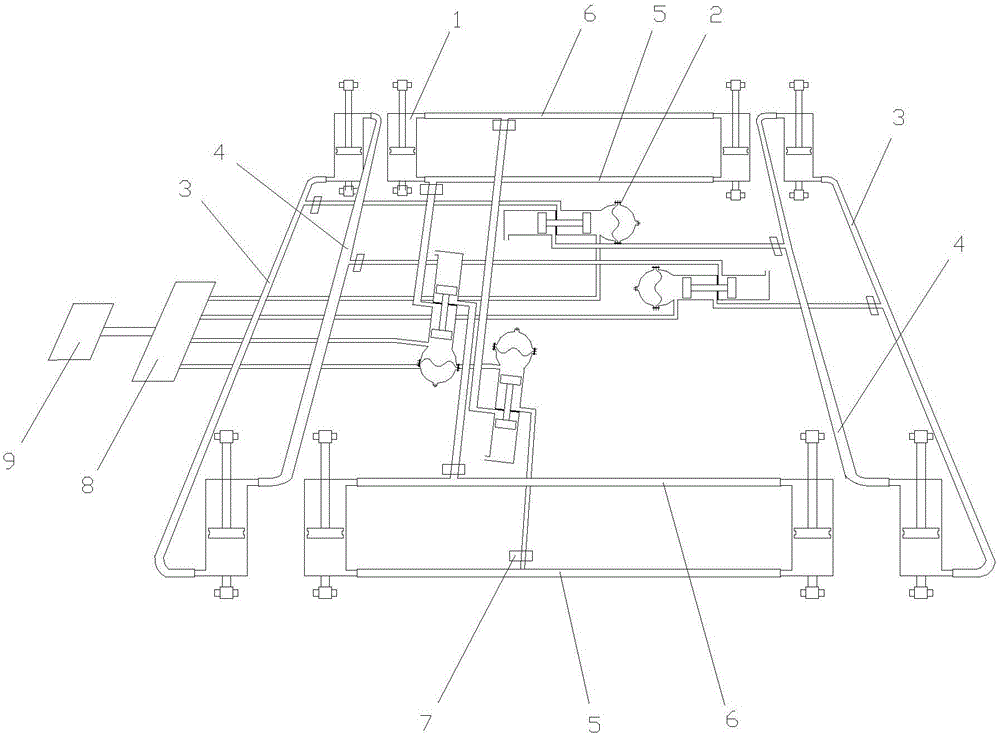

[0035] Such as figure 1 As shown, the hydraulically interconnected suspension system that realizes anti-pitch, anti-roll, cross-lift and anti-torsion includes a hydraulic cylinder 1 and a pressure shock absorber 2; the hydraulic cylinder 1 is arranged on the upper side of the wheels of the car, and the upper side of each wheel There are two hydraulic cylinders 1, the lower parts of the two hydraulic cylinders 1 on different wheels at the same end are connected through the first pipe 3 and the upper parts are connected through the second pipe 4, and the remaining parts on the different wheels at the same end The lower part of the lower hydraulic cylinder 1 is connected with the lower part of the remaining hydraulic cylinder 1 on the different wheels at the other end through the third pipeline 5 and the upper part is connected through the fourth pipeline 6; the first pipeline 3 is connected with the second pipeline on the opposite side through the pipeline. The pipeline 3 is con...

Embodiment 2

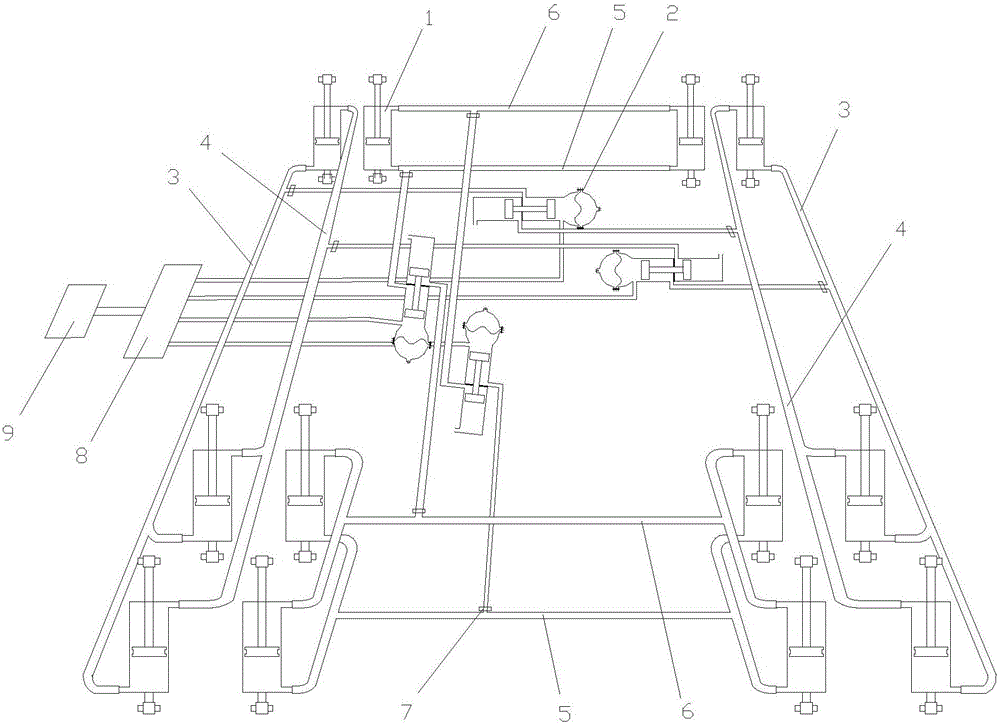

[0038] Such as figure 2 and 3 As shown, when used on a six-wheeled vehicle, the two wheels on the same end and side are regarded as the same group of hydraulic cylinders. The upper part and the upper part, the lower part and the lower part of the same group of hydraulic cylinders are connected by pipelines in pairs. The hydraulic cylinders connected in pairs in the same group of hydraulic cylinders are connected in the same way as one hydraulic cylinder in a four-wheeled vehicle. Other structures are consistent with Embodiment 1.

Embodiment 3

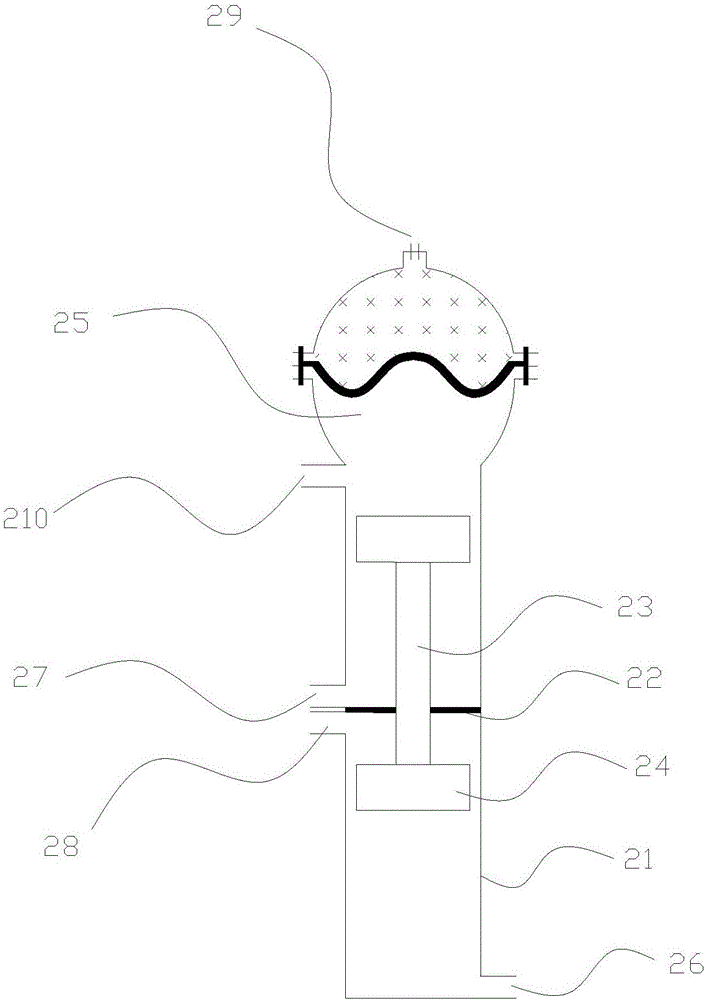

[0040] Such as Figure 4 and 5 as shown,

[0041] A hydraulically interconnected suspension system that realizes anti-pitching, anti-rolling, cross-lifting, and torsion reduction, including a hydraulic cylinder 1 and a shock absorber 2; the hydraulic cylinder 1 is set on the upper side of the wheels of the car, and two hydraulic pressure Cylinder 1, the lower parts of the two hydraulic cylinders 1 on different wheels at the same end are connected through the first pipe 3 and the upper parts are connected through the second pipe 4, and the remaining hydraulic cylinders on different wheels at the same end The lower part of 1 is different from the other end respectively. The lower part of hydraulic cylinder 1 left on the wheel is connected through the third pipeline 5 and the upper part is connected through the fourth pipeline 6; the shock absorber 2 is connected to the first pipeline 3, the second pipeline 4, Between the third pipeline 5 and the fourth pipeline 6 .

[0042] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com