Mining pattern of load meridian automobile tire

A technology of automobile tires and radials, which is applied to tire treads/tread patterns, heavy tires, heavy vehicles, etc., can solve the problems of insufficient lateral grip, slow heat dissipation, and easy sideslip of tires, so as to prevent premature aging and reduce The effect of creeping temperature rise and service life enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

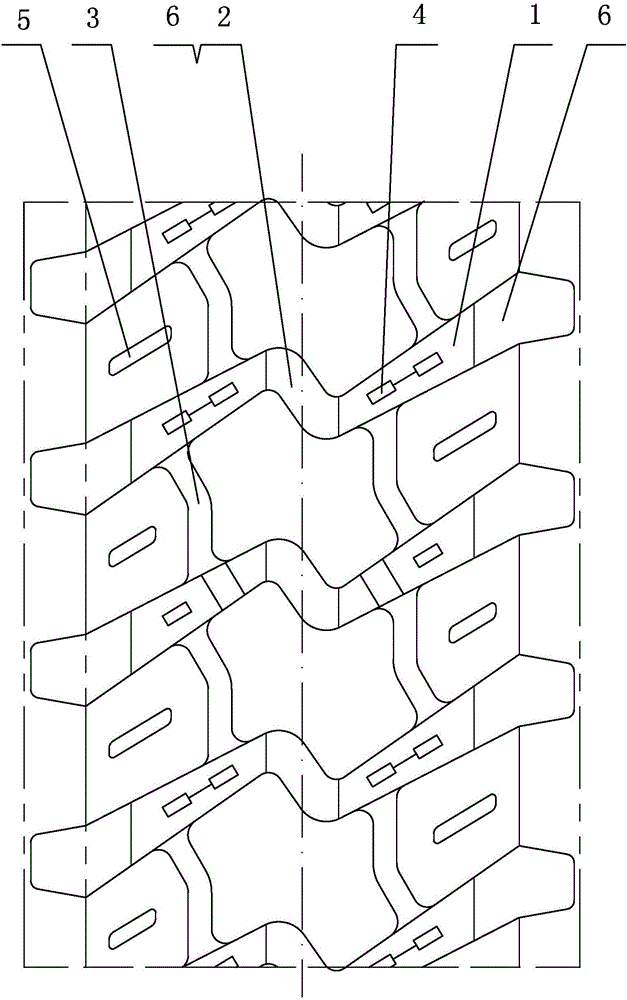

[0024] The mining pattern of the radial truck tire of the present invention includes pattern grooves, and pattern blocks are formed between the pattern grooves.

[0025] The pattern grooves are respectively opened on the tire shoulders, tire crowns and sidewalls on both sides of the tread centerline:

[0026] On the shoulder on the left side of the tread center line and on the crown, the left oblique long groove 1 is set in parallel intervals, and on the shoulder and the crown on the right side of the tread center line, the right oblique long grooves are arranged in parallel intervals 1. The oblique long grooves 1 of the left and right positions have the same inclination direction, the positions of the corresponding left and right oblique long grooves 1 are staggered, and the left and right oblique long grooves 1 with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com