Mould molding slide block as well as production method thereof and production system thereof

A mold forming and production method technology, which is applied in the field of mold processing, can solve the problems that the product cannot achieve sharp edges and other problems, and achieve the effect of avoiding the low life of the mold, improving the life of the mold, and improving the appearance of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0038] In order to solve the problem of producing the injection mold of the target product in the existing technology through the copper processing method, due to the natural consumption of electric discharge machining, the ridge line of the product mold that originally needs a sharp edge effect is also processed into a naturally consumed rounded corner, which affects the product. Regarding the appearance effect, this embodiment provides a molded slider, through which the product obtained by injection molding the molded slider can directly obtain a sharp edge effect and improve the appearance effect of the product.

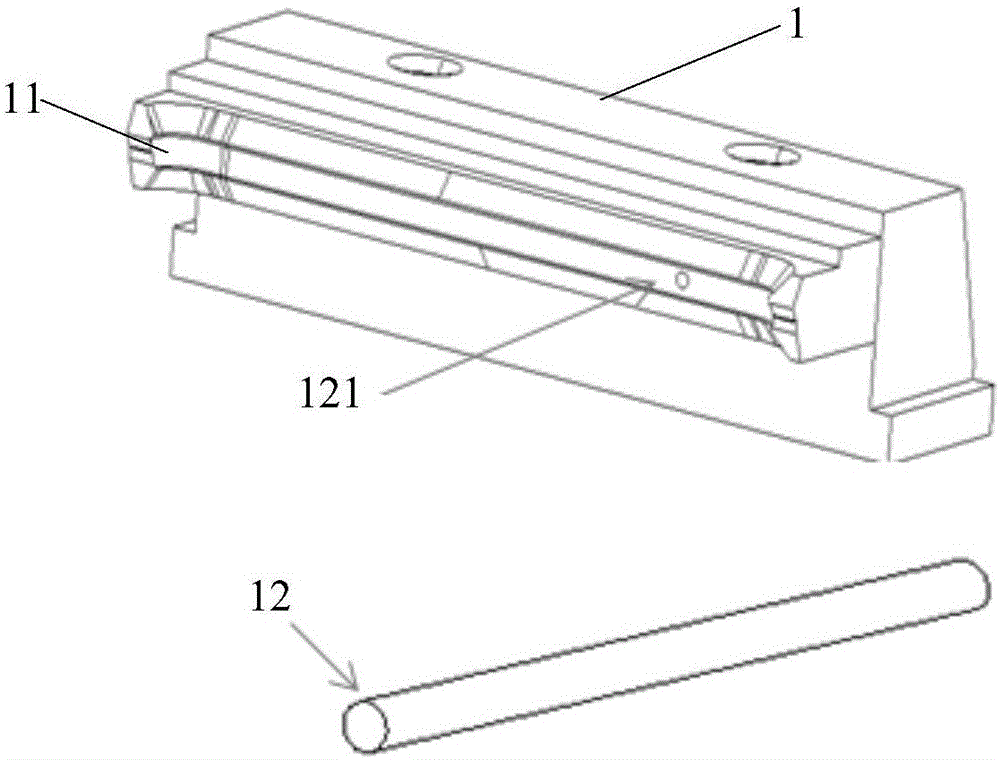

[0039] Please refer to figure 1 , figure 1 Structural diagram of the mold forming slider provided for this embodiment.

[0040] In this embodiment, the mold forming slider 1 includes: a processing surface 11, which is used to process the product side of the target product, and the processing surface 11 is directly processed by a profiling forming knife.

[0041]...

no. 2 example

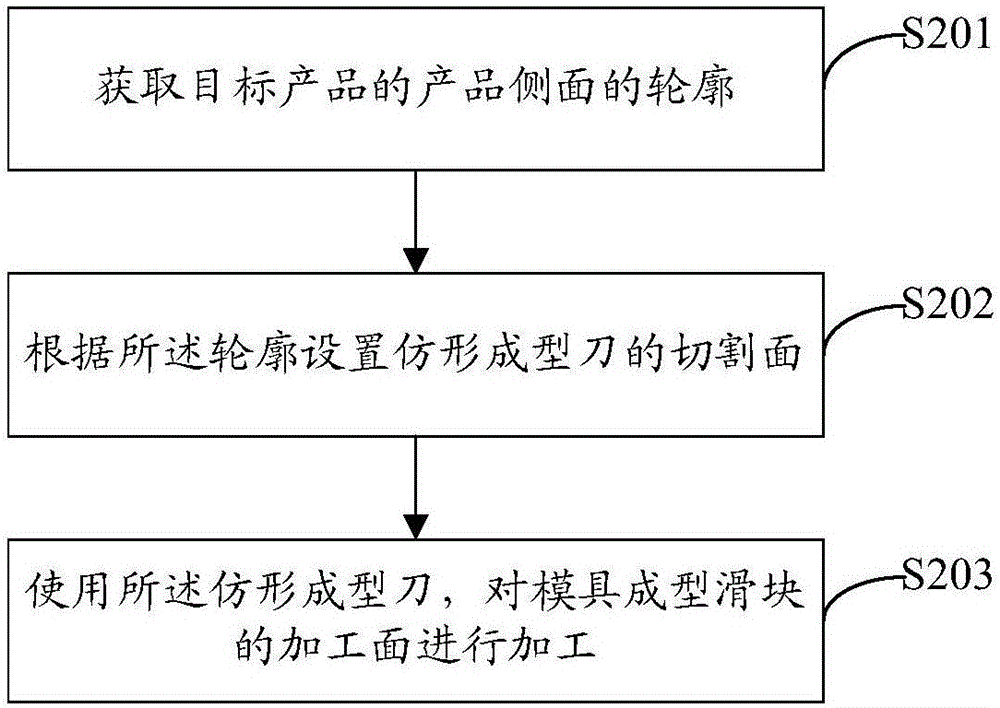

[0048] See figure 2 , figure 2 The flow chart of the production method of the mold forming slider provided in this embodiment, the method is mainly used to produce the appearance product with sharp corners, and realize the sharp edge effect of the product. Specifically, the processing steps of the method are as follows;

[0049] S201. Acquire a profile of a product side of a target product.

[0050]In this embodiment, obtaining the profile of the side of the target product can specifically be analyzed by designing the software of the target product, analyzing the design parameters of the ridgelines and sharp angles in the profile of the product, and the positions of holes, grooves, etc. on the side of the product. Structural parameters such as protrusions, etc., these parameters are the outline of the target product; design the mold slider according to the above parameters obtained from the analysis.

[0051] S202, setting a cutting surface of the profiling knife according...

no. 3 example

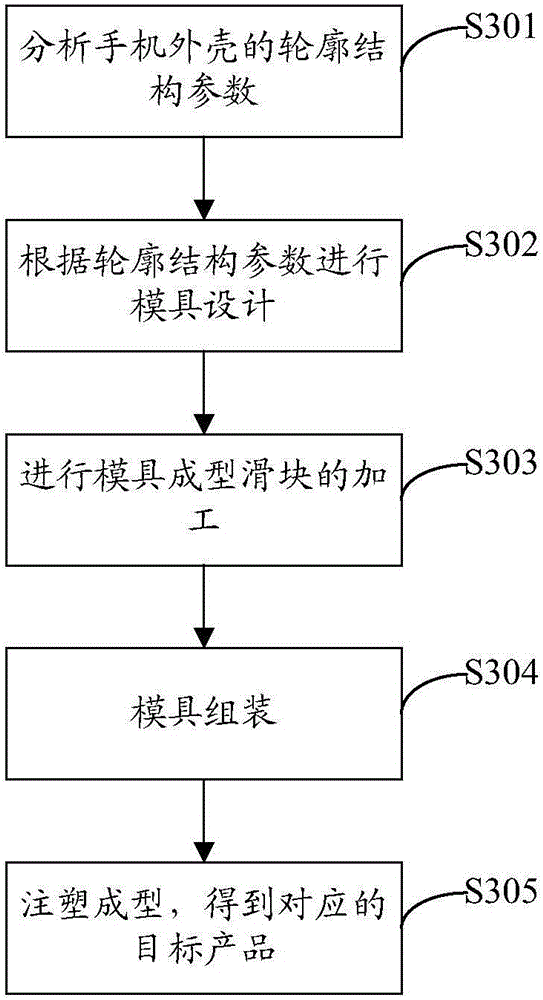

[0061] See image 3 , image 3 The specific flow chart of the production method of the molded slider is provided for this implementation. In this embodiment, the mobile phone casing is taken as an example to further illustrate the production method of the molded slider of the present invention.

[0062] In this embodiment, the processing steps of molding the slider of the mobile phone shell include:

[0063] S301. Analyze the contour structure parameters of the mobile phone case. Specifically, the contour structure parameters include the inclined plane on the surface of the mobile phone case, the angle formed between the inclined plane and the inclined plane, whether each included angle is a sharp angle, and the position and location of the holes on the mobile phone case. Hole shape parameters, location parameters, etc.

[0064] Such as Figure 4 , 5 As shown in FIG. 2 , they are the structural diagram and partial enlarged view of the mobile phone case provided by this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com